Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

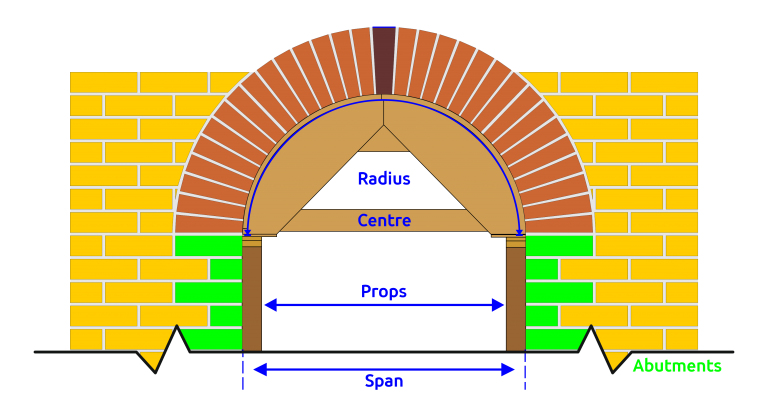

Arche Centres are temporary timber support during the construction of an arch, they are needed when forming an opening over and openings like doors, windows or passageway.

The timber’s centre must be strong enough to carry the load imposed upon it during the construction of the arch until the mortar has set, otherwise, a total collapse of the arch will occur.

There are two common types of temporary supports one is a Turning Piece and the other is an Arch Centre, both have a radius enabling bricks or stone to be laid on top of the centre with even joints.

There are several types of arch centres depending upon the type of arch constructing, all have the same basic principle, that arch must span the opening which sits inside the abutments and has a radius enabling the bricks or stone to sit on until arch is set.

Supporting the arch centre is normally done by timber props or masonry units as long as they are stable without toppling over during construction.

Parts of a Arch Centres

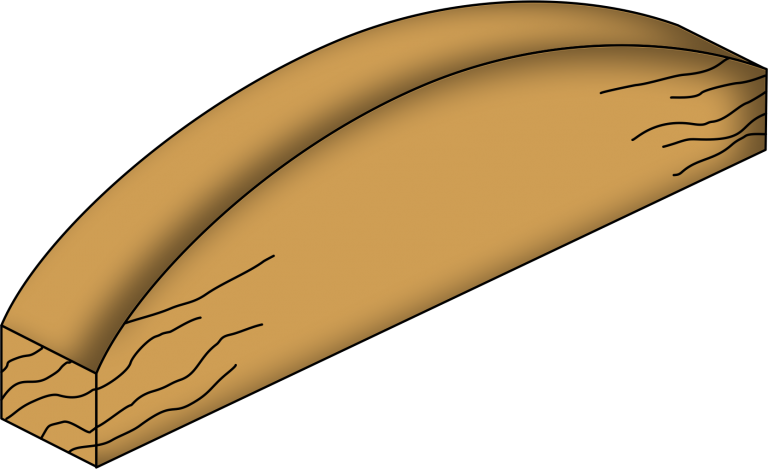

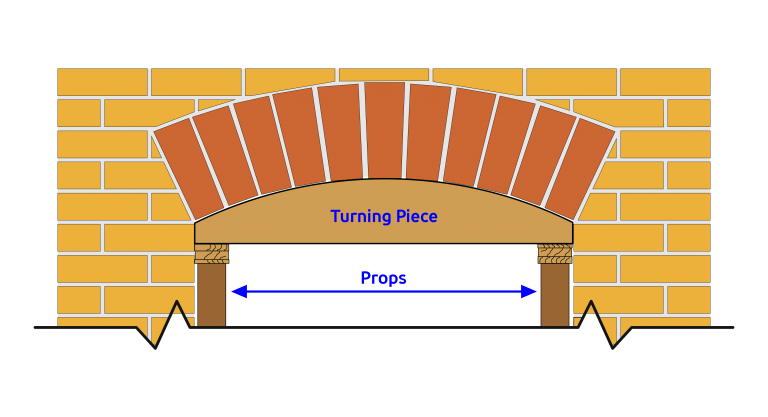

A Turning Piece

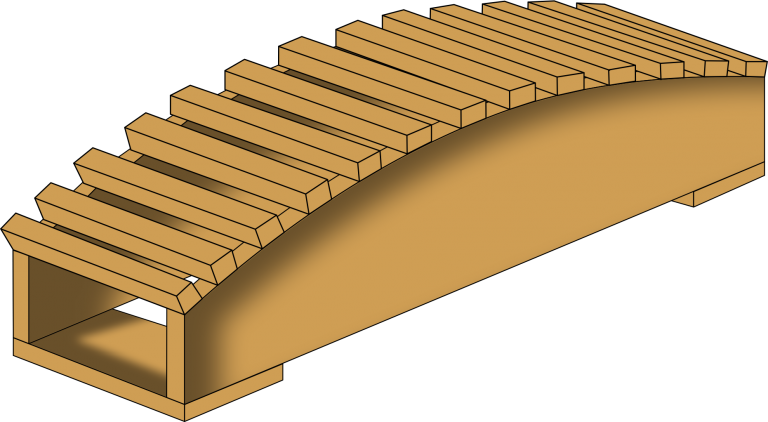

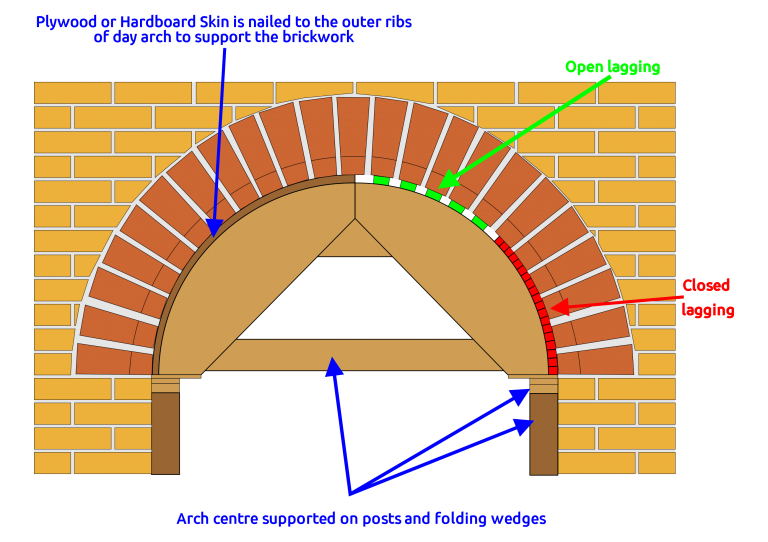

Turning Piece with Open Lagging

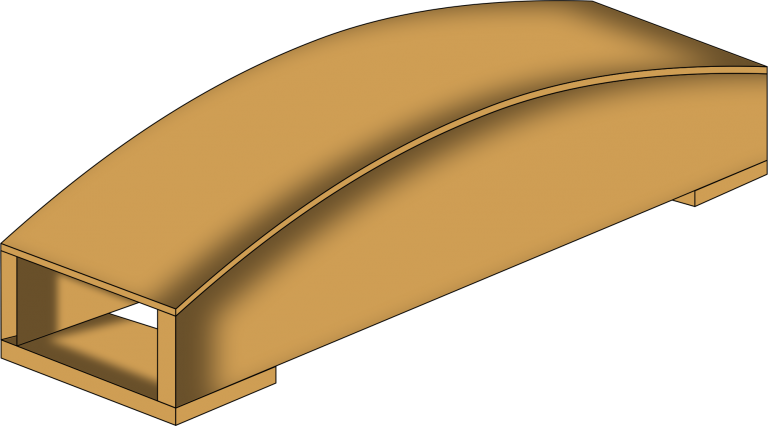

Turning Piece with Closed Lagging

A turning piece is normally constructed out of a solid piece of timber or several sections of timber forming a turning piece with open or closed lagging.

Turning piece is normally constructed for small opening sizes and out readily available timber on site which are generally 225mm and have a thickness of 75 to 200mm which is then cut to the shape of the arts and supported by props.

Turning Piece

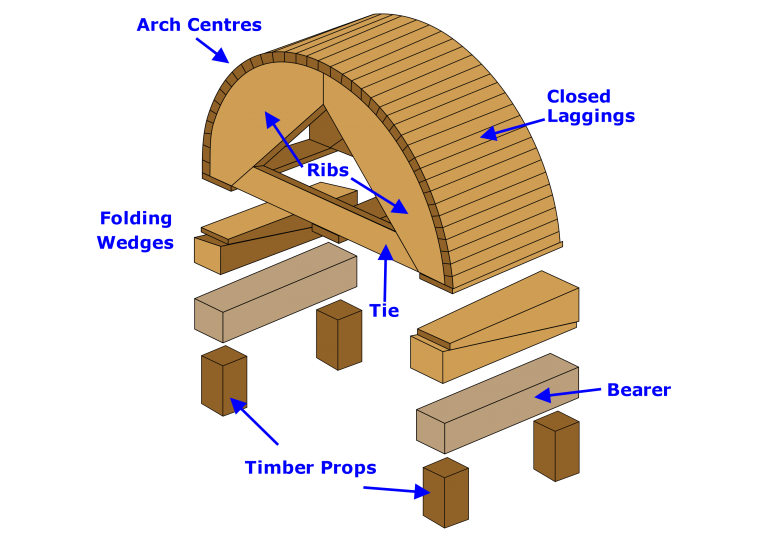

Parts of a Arch Centres

Arch centres are generally used for larger openings, the centre can have close lagging provide a continuous surface on which to mark out the voussoirs.

Just like a turning piece, you can have open lagging enabling you to remove excess mortar from the soffit of the arch (Intrados) to avoid staining of the bricks or stone.

Alternative methods instead of using strips of wood is to use Plywood or Hardboard, extra care is needed when buttering the bed of the brick to avoid excess mortar being squeezed out of the face of the header onto the top of the centre.

Arch centres can be simple with a single striking point or more complex arches which has several striking points like Four Centred Gothic Arches.

Parts of a Arch Centres

To support arch centres you need timber props with bearers on top.

Folding wedges are made from timber to the same dimensions and the length is slightly longer than the width of the arch this will prevent the centre from rocking.

The wedges are placed underneath the purpose-made timber centre but on top of the supporting post at each end of the opening.

During the process of setting out the centre. bricklayer or stonemason can make slight adjustments by sliding the wedges over themselves to raise or lower the timber centre and to ensure it is level.

When removing the timber centre, the folding wedges are gently removed enabling the centre to rest on to the supporting post.

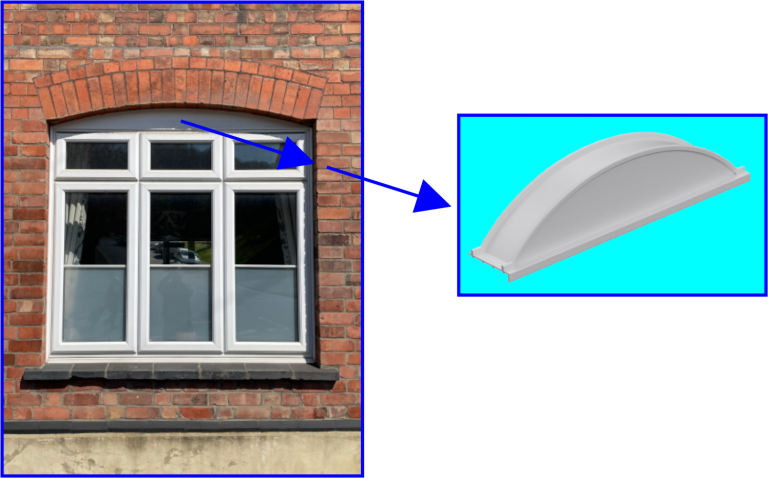

The arch former is made out of Extruded from PVC-u for greater UV stability, the arch centres are designed to weather just like PVC-u windows.

PVC-u arch former resting upon the flange of a steel lintel and can be removed when the arch is formed and the mortar is set, or it can be left in as a feature and is ideal when flat-topped windows or doors are to be fitted into the structure

Arch Former

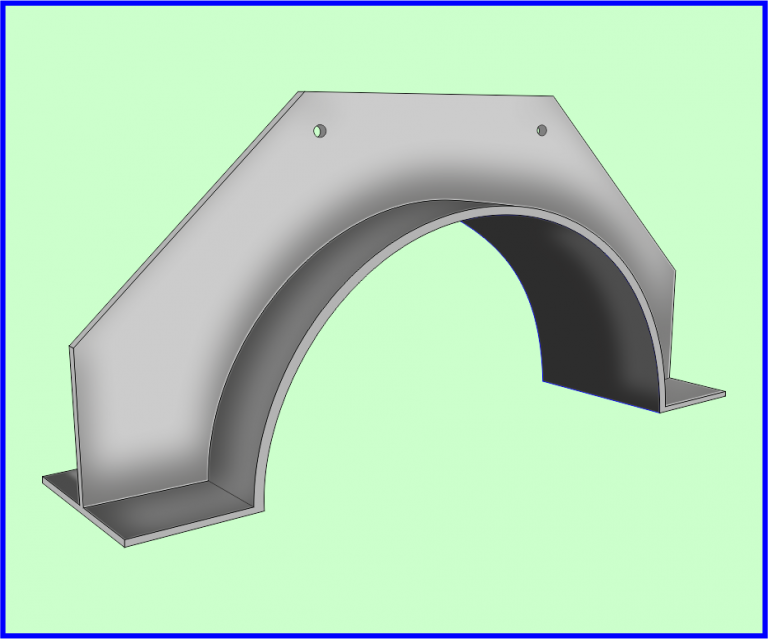

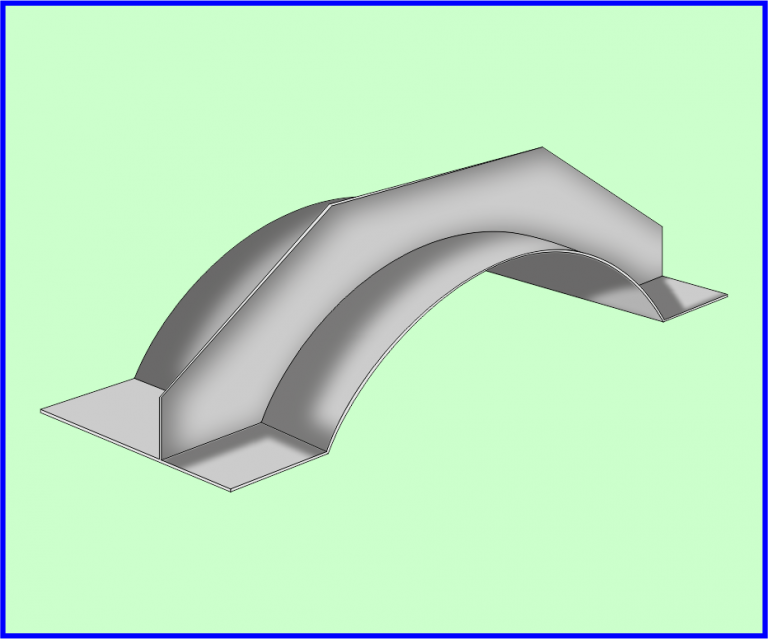

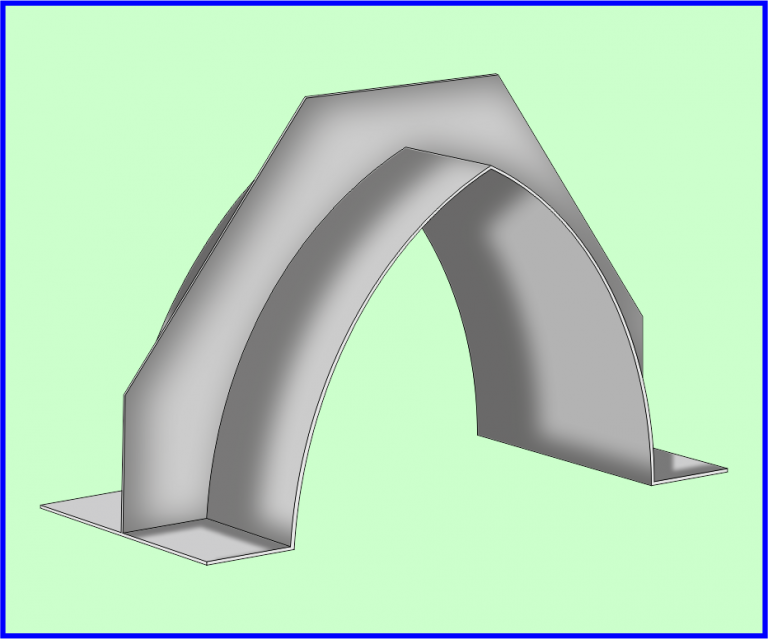

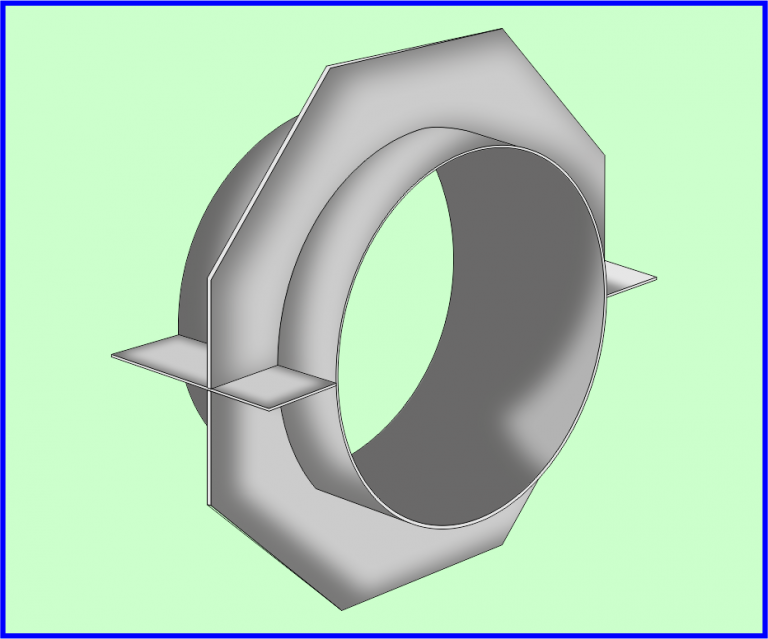

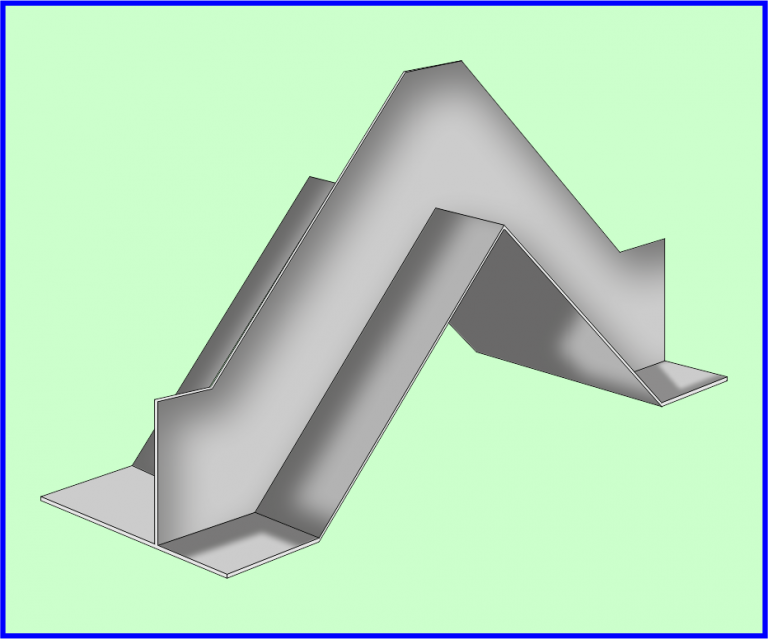

Modern techniques used steel arch shapes which are custom-made arch formers, they eliminate temporary arch centres and form part of the structure acting as a lintel over an opening.

Below is a selection of still arch shapes.

Semi-Circular Arch

Segmental Arch

Gothic Arch

Bull’s-Eye Arch

Apex Arch Arch