Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Aim

Learning outcome

Assessment Criteria

The learner can:

1.1 identify Personal Protective Equipment (PPE) appropriate to

constructing frames using through mortice and tenon joints have already been covered in the following link

Personal Protective Equipment (PPE)

1.2 identify Materials required to construct frames using through mortice and tenon joints.

Has already been covered in the following link.

1.4 identify Tools and Equipment required to construct Through Mortice & Tenon Joints.

The following tools have already been covered in the previous section.

Try Square

Mortice Gauge

Rule

Tenon Saw

Bevel-Edged Chisel

Bench Hook

G-Cramp

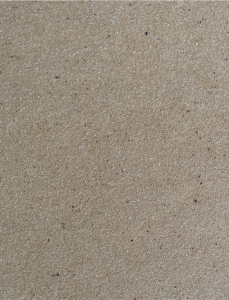

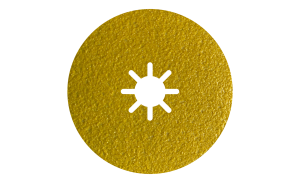

Glasspaper originally manufactured by crushing glass into a fine powder, Sand was also used this where the name sandpaper comes from wrongly used.

There are several different types of glasspaper choose from some are made from natural materials like flint, garnet and emery.

Synthetic abrasives like aluminium oxide and silicon carbide both are tougher than natural materials and last longer the toughest one is silicon carbide.

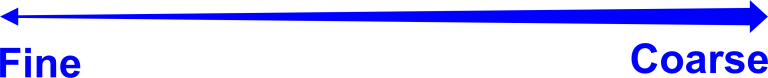

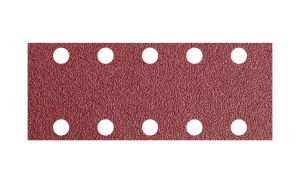

Abrasives glasspaper comes in different lengths, sizes and shapes the most common one for small jobs are packets of various grade grit sheets, making it easy to take a surface from rough to finish.

P240

P100

P60

P40

Sheet Glasspaper

Palm Glasspaper

Belt Glasspaper

Glasspaper has a range of grit sizes are used to remove material from surfaces like old paint or sanding painted layer between coats to make them smoother.

Preparation for glueing requires the area to make the surface rougher with sandpaper to make a good contact surface for the glue

Grit size normally printed on the back of glasspaper with a letter P before the number, the number indicating the size of the grit.

P20 to P36

Roughing up surfaces ready for glue

P40 to P50

Removal of rough materials

P80 to P120

Preparation for finishing and for removing stains

P150 to P180

Final step before finishing

P220 to P240

Sanding Between Coats

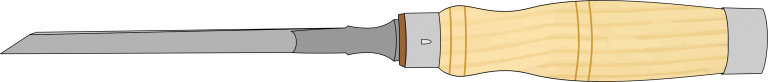

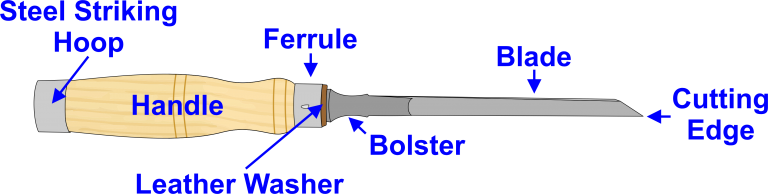

Mortise chisels are designed for chopping out a mortise and levelling out waste material.

The Steel Striking Hoop is designed to receive heavy blows with a wooden mallet and can cut across the grain.

The construction of the blade is thicker than a normal chisel which is the only chisel able to lever out waste material.

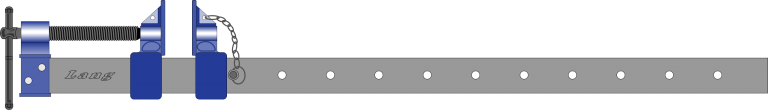

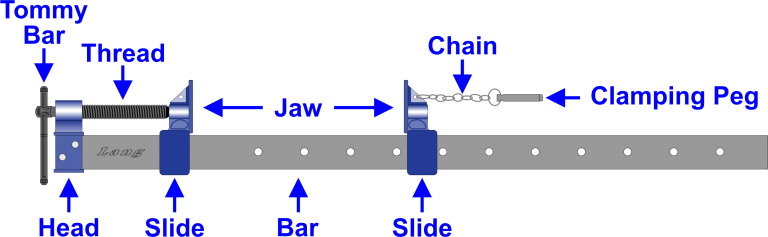

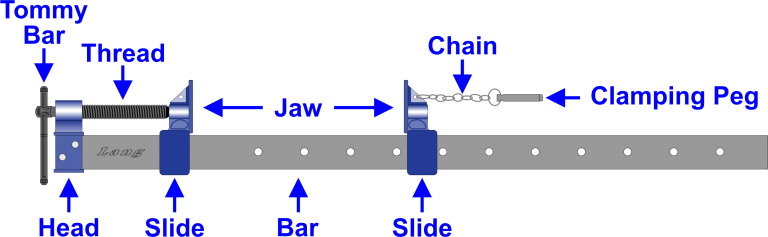

Sash clamps have a wide range of uses, used to glue up panels and help with the assembly of units.

The flat bar has dimensions 40mm wide, 10mm thick and 600mm long, which also incorporates a series of 6mm holes at 100mm part to accept the clamping pin.

Objects are placed between the two sliders, ensuring the slide and nearest the head has enough thread to clamp the object against the opposite slider which is held in place with a clamping pin.

The head is fixed to the end of the bar which incorporates a Tommy bar, thus enabling you to loosen or tighten the jaw with a screw thread.

T Bar Clamp is a robust clamping for heavy-duty applications which has the option of fitting to a workbench.

The only difference between the SA Sash Cramp and ST Sash Cramp is the sliders do not in case the bar.

The sliders only go down as far as the clamping holes, this allows free movement when attaching to a workbench.

You can purchase Sash clamp heads which are fitted onto any length of wooden batten which needs a series of holes for the clamping pin, this alternative is only suitable for light duties.

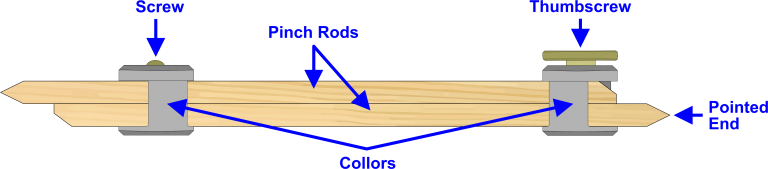

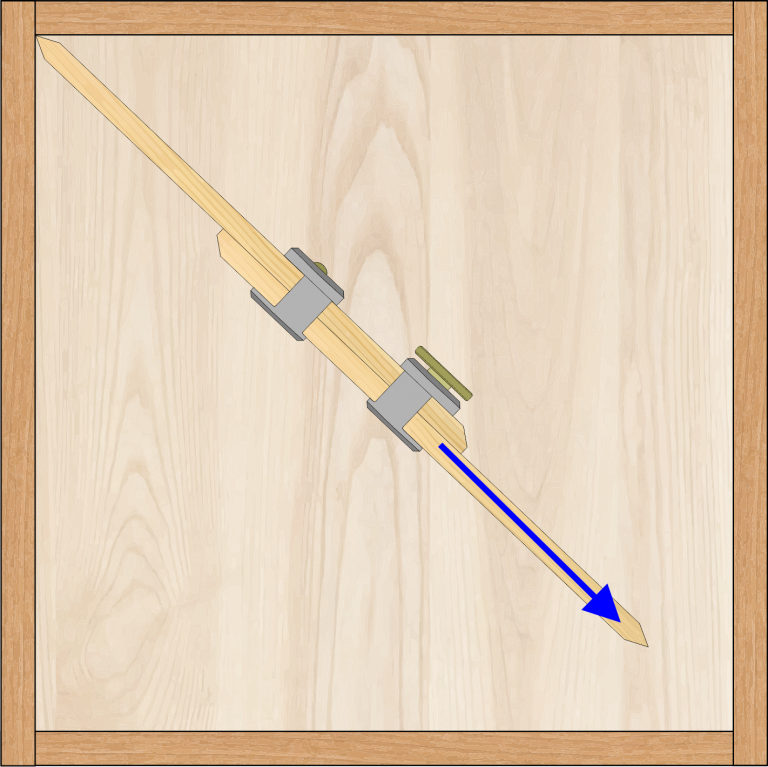

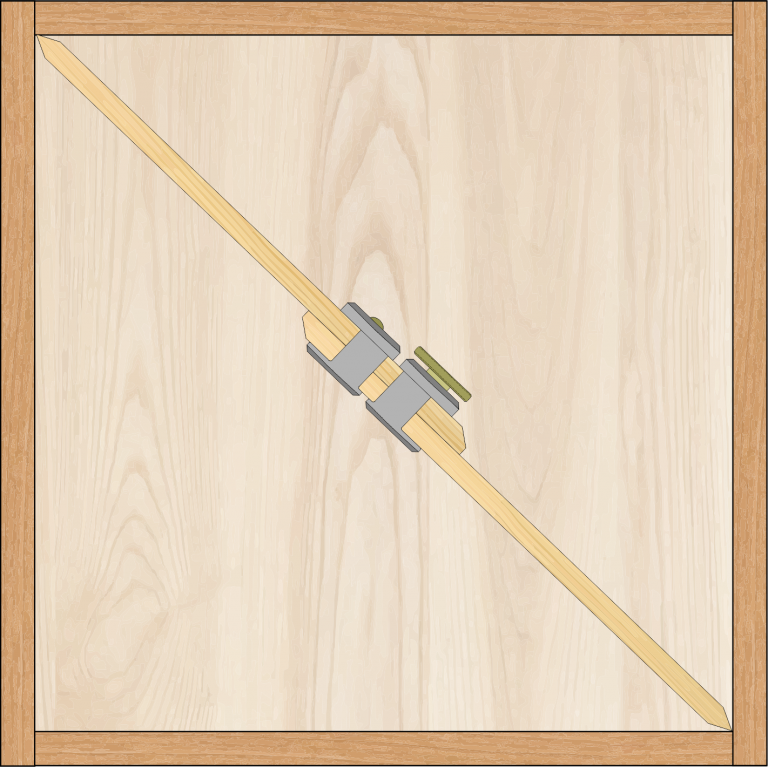

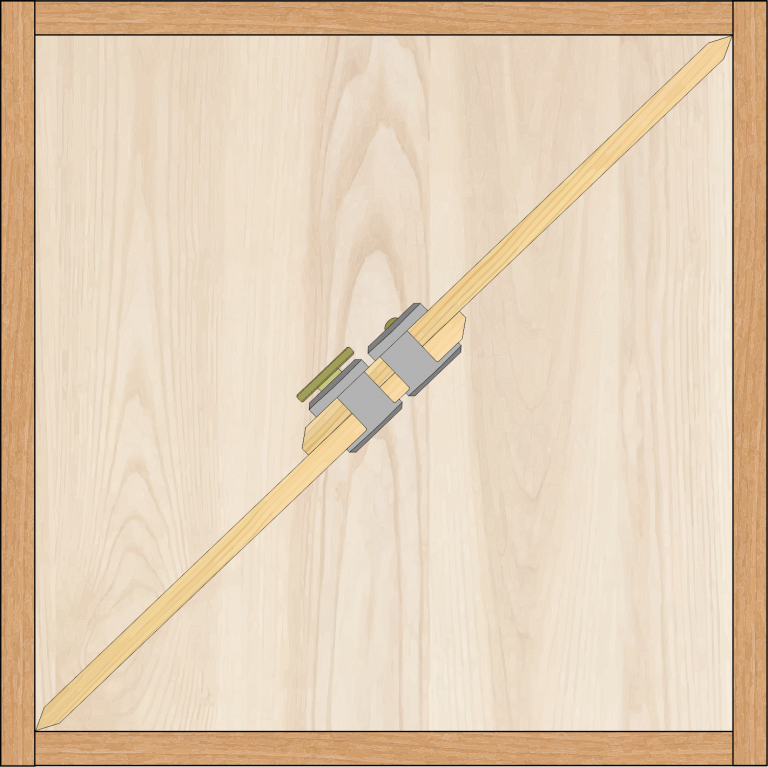

A Pinch Rod is designed to check the diagonals to ensure the frame or casework is perfectly square.

Pinch Rod comprises two pieces of wood that have two sharpened points and is cut back to allow access into internal corners.

To keep the pinch rods together there are two collars one with a normal screw and the other with a thumbscrew.

you need to undo the screw and Thumbscrew just enough allowing the rods to move freely, place a one-pointed pointed end into the top left-hand corner.

Extend the other pointed end so it’s inside the internal corner on the bottom right-hand side, doublecheck both points are in the internal corners then tighten the Thumbscrew.

Remove the pinch rod from the left-hand internal corner and rotate so it fits inside the opposite internal corner, if both points just fit inside the top right-hand corner in the bottom left-hand corner then the frame or casework is perfectly square.

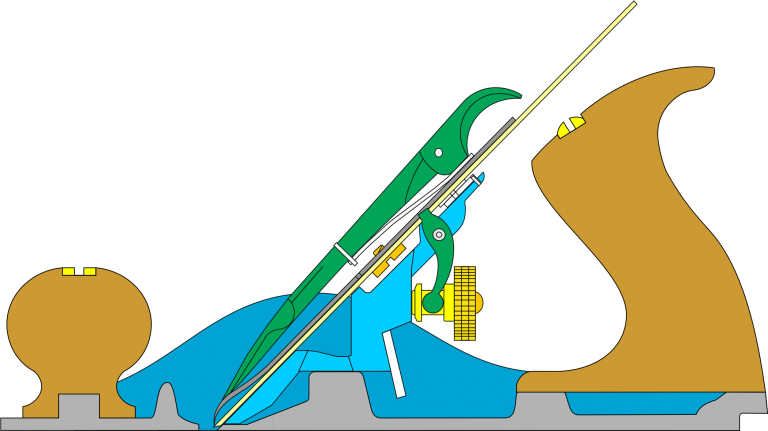

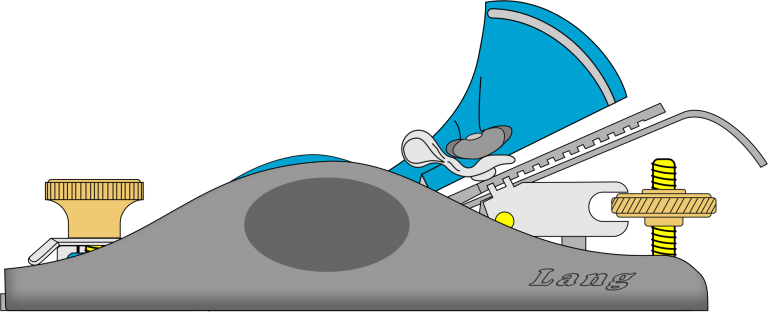

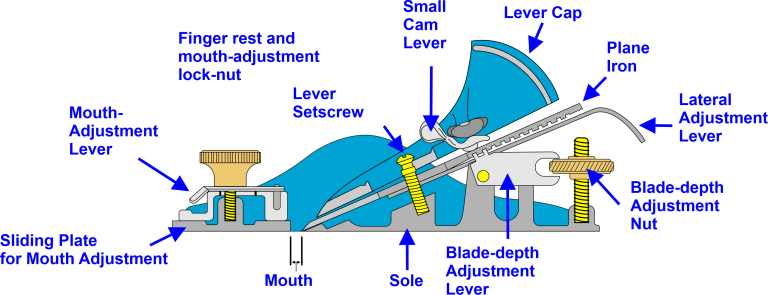

The smoothing plane is similar in design to the metal jack plane except that the length of the sole is much shorter and the plane blade is ground and sharpened with corners slightly rounded.

This plane is capable of taking off very thin shavings from all over the surface of the timber.

The purpose of this is to leave the finished timber clean and smooth with no previous plane marks showing.

This type of plane is very popular as it is easy to handle and can be used for all kinds of work.

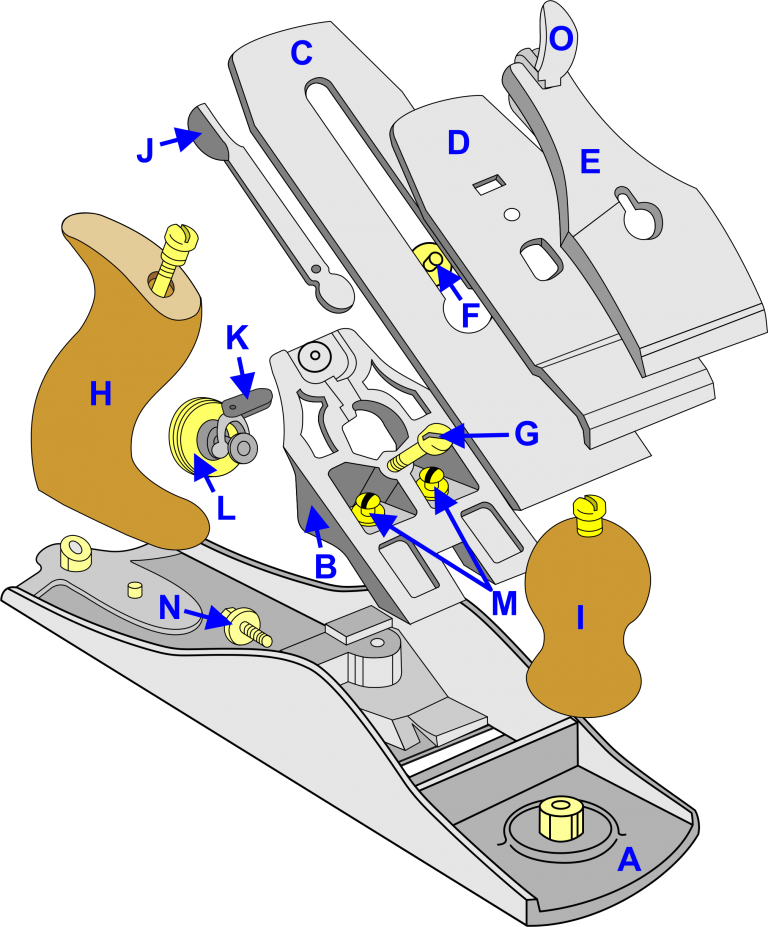

A – Plane Body

B – Frog

C – Plane Blade

D – Chip-breaker

E – Cap

F – Chip-breaker Screw

G – Blade/Cap Screw

H – Tote

I – Knob

J – Lateral Blade Adjustment Lever

K – Blade Depth Lever

L – Fine Adjuster Nut

M – Frog Attachment Screws

N – Mouth Opening Adjustment Screw.

O – lever cap

This plane is used for small general work.

It is designed to be used both single and double handed.

It is capable of tackling some of the most awkward cross-grained timbers.

The blade of this plane is pitched at 20˚ and mounted with the bevel upwards.

The depth of cut can be controlled by means of an adjusting nut, and the mouth of the plane can also be altered to suit different types of work.

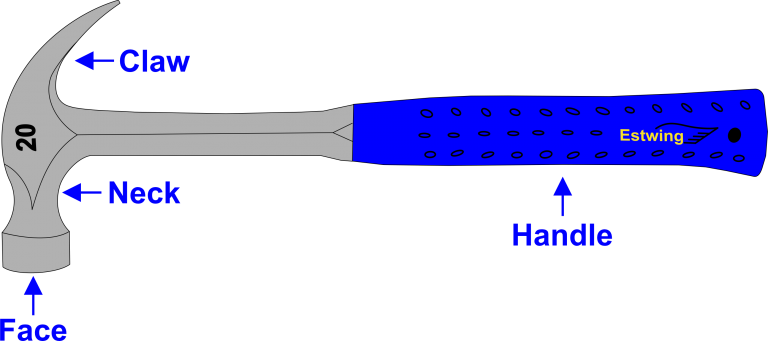

There are a number of types of hammer available to the carpenter and joiner, but the most

commonly used hammer is the claw hammer.

It can be used to extract nails and so it saves the carpenter carrying pincers with him.

Hammers may be obtained in various weights and sizes.

The very smallest hammer is known as a pin or tack hammer.

The hammer used by joiners and cabinet makers is the warrington hammer.

This hammer is lighter than a claw hammer and has a cross pein instead of a claw.

Hammer handles are usually made from ash or hickory but modern claw hammers now

have rubber or plastic handles and some expensive hammers have leather handles.

Where the hammer has an ash or hickory handle ,the head of the hammer is secured in

place by means of wooden and malleable iron wedge.

The striking face of the hammer is slightly rounded to prevent it from marking the timber

badly if it should come into contact with by accident.

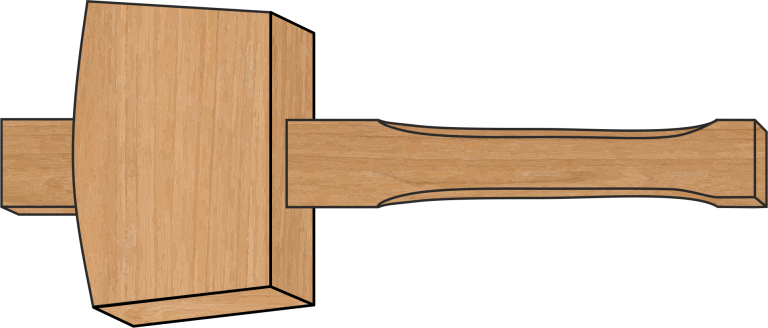

Mallets are made from wood, usually beechwood, and are used to strike the handle of wood-cutting chisels.

The mallet is designed so that the head of the mallet provides a large striking face.

The shaft of the mallet is tapered to make it self tightening during use.

Many joiners prefer to make their own mallet, in which case it can be shaped to suit their own hand.

When using the mallet, never strike the chisel with the side of the mallet always use one of the two strike faces, otherwise the mallet will crack or break.

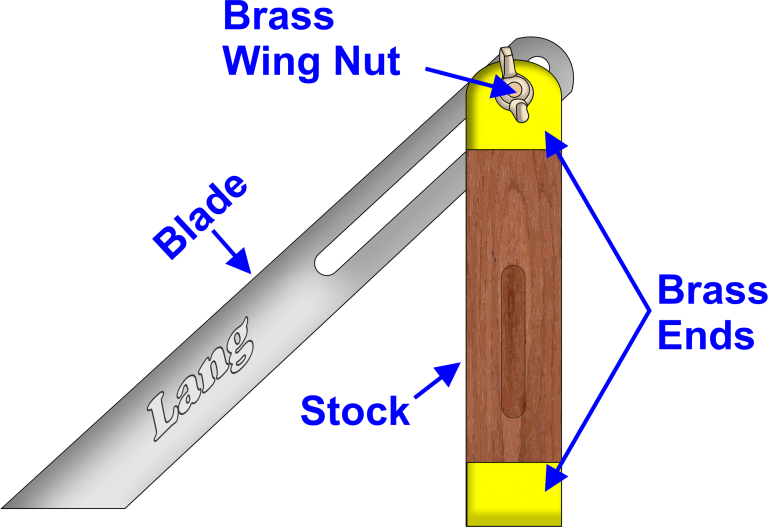

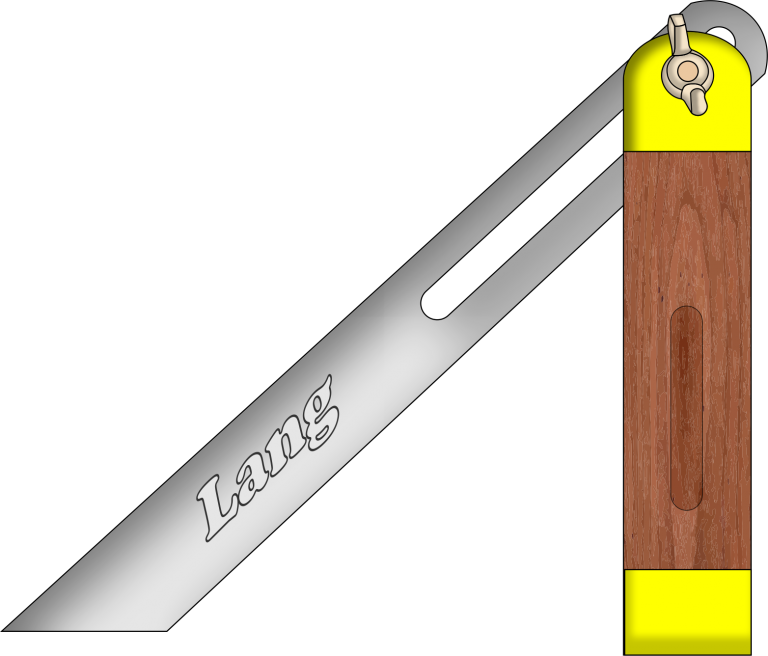

Parts of a Sliding Bevel

The sliding bevel is made up of two components, the blade and the stock.

Bevel stock is made from high quality and hard-wearing African Rosewood with brass ends fitted to prolong the life of the stock.

Chemically blue blade to prevent corrosion, which can be adjusted to various angles and can be locked into position using a Brass Wing Nut.

This is useful for transferring the same angle onto timbers or masonry units.

Sliding Bevel