Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Aim

Learning outcome

Assessment Criteria

The learner can:

1.3 state the process required to mark out frames using through mortice

and tenon joints

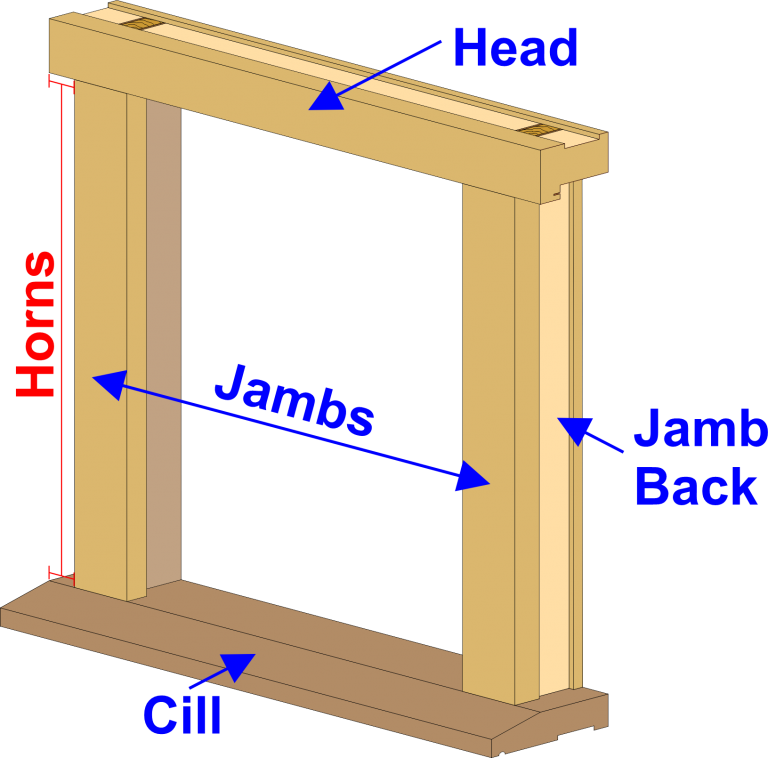

Cill

Cill is the bottom component part of the door frame, the cill keeps the vertical door Jambs in place.

Jambs

The door frame jambs run vertically up either side of the door frame which in turn is fixed to the exterior reveals of the door opening.

The door is fitted to the Hinge Jamb by two or more hinges, On the opposite side is a Latch Jamb which has a mortise for Strike Plate this enables you to open and lock the door.

Header

The horizontal header is the top part of a door frame.

Horns

The horn is the projection of horizontal members of the frame at the bottom and top.

The main advantage of the horn is that it fixes the frame in a wall opening.

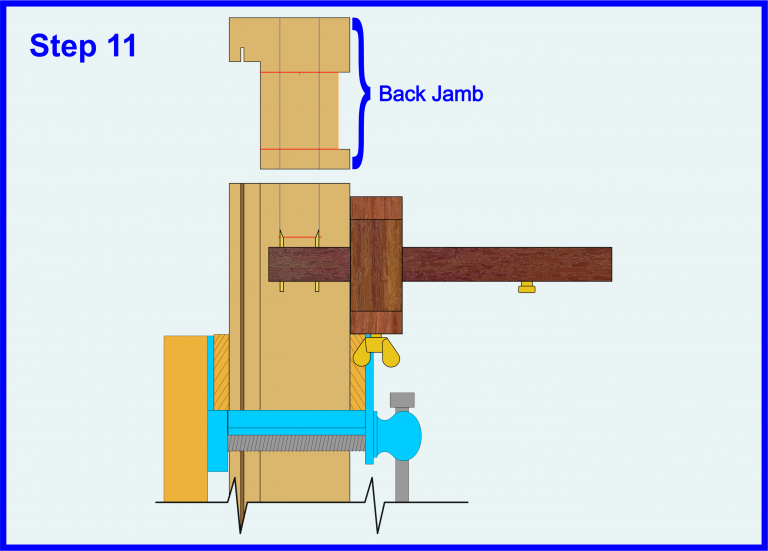

Jamb Back

The Jamb Back is a recess for receiving Frame Cramps are used when installing door and window frames into masonry.

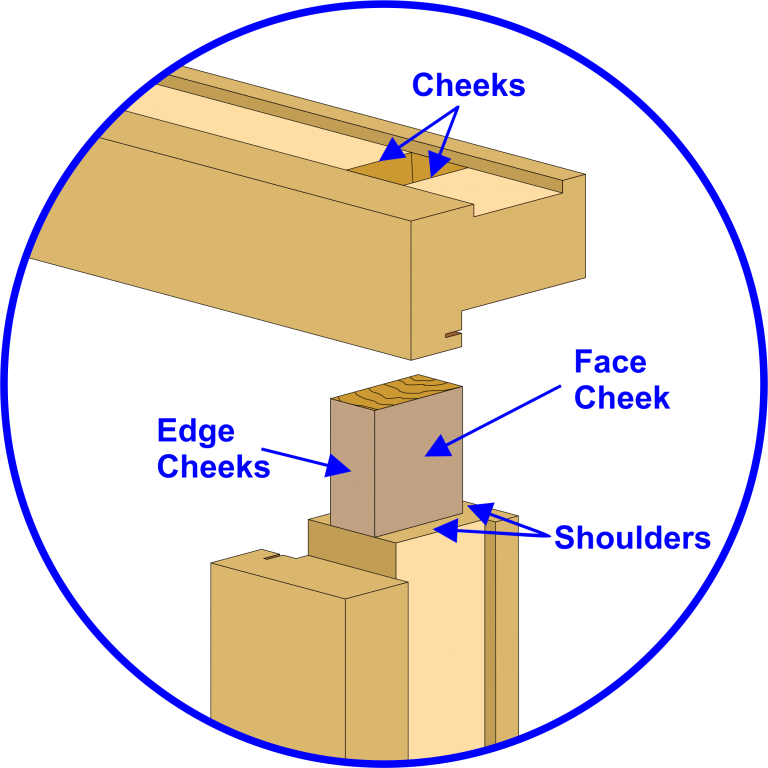

One of the strongest joints in woodwork is mortise & tenon joints which have two components, the mortise and the other being the tenon tongue which is fitted inside the mortise with additional timber wedges making a simple but strong joint.

There are several mortise & tenon joint variations, in this assessment we are doing a through tenon joint, this is where the tongue of the tenon joint extends to the opposite face of the mortise.

Parts of Through Mortice & Tenon Joints

Now we have covered the parts of the door-frame and parts of a Through Mortice & Tenon Joint.

The materials in this assessment will be, slightly from Training Centre to Training Centre but the basic method of marking out the door-frame using through mortice and tenon joints will be the same.

Training centres can either buy in door-frame kits or rebate their timbers within the training centre itself following the assessment criteria on the practical activity.

You can see the specifications under the following heading, 6219 Units Carpentry & Joinery which is in the following link below

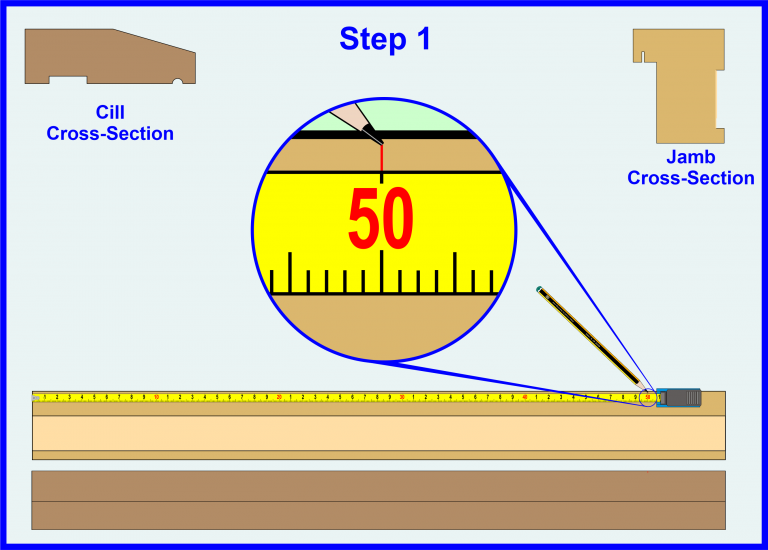

Through Mortice & Tenon Joints Step_01

Select your Header and Cill components for your timber frame, marked at 500mm or 50cm on the Jamb Back part of the Header and on the top part of the Door Frame Cill

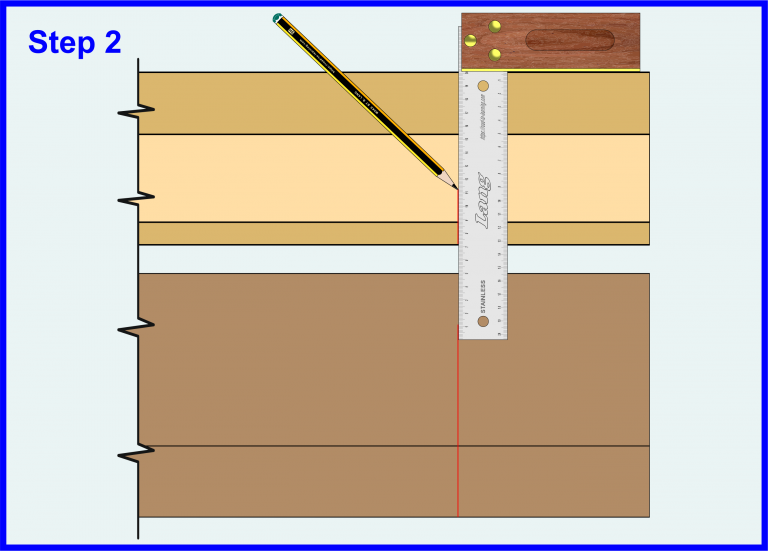

Select a combination square or try square to transfer the previous mark around all surface faces of both components, checking the line meets up with the first pencil mark.

By transferring the mark to all face sides will help you to cut squarely with a hand saw.

Through Mortice & Tenon Joints Step_02

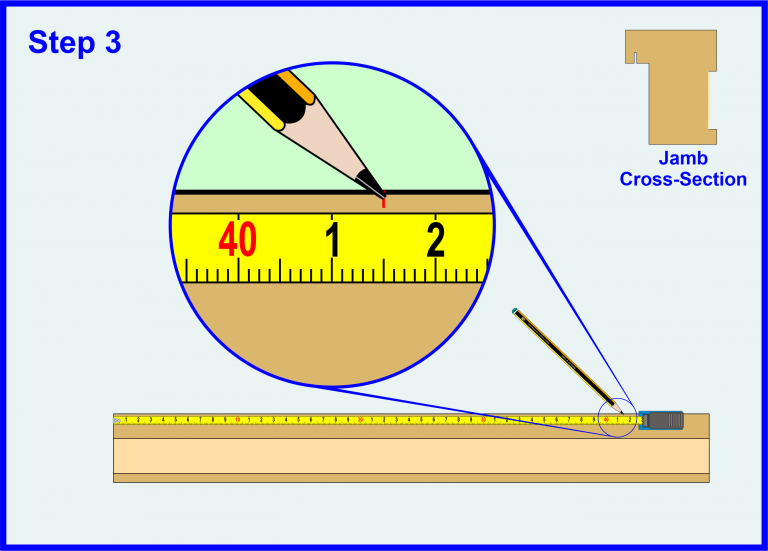

Through Mortice & Tenon Joints Step_03

The last two components for the Door Frame is the Hinge Jamb and the Latch Jamb which are cut to 415mm

As before select a combination square or try square to transfer the previous mark around all surface faces of both Jamb, checking the line meets up with the first pencil mark.

By transferring the mark to all face sides will help you to cut squarely with a hand saw.

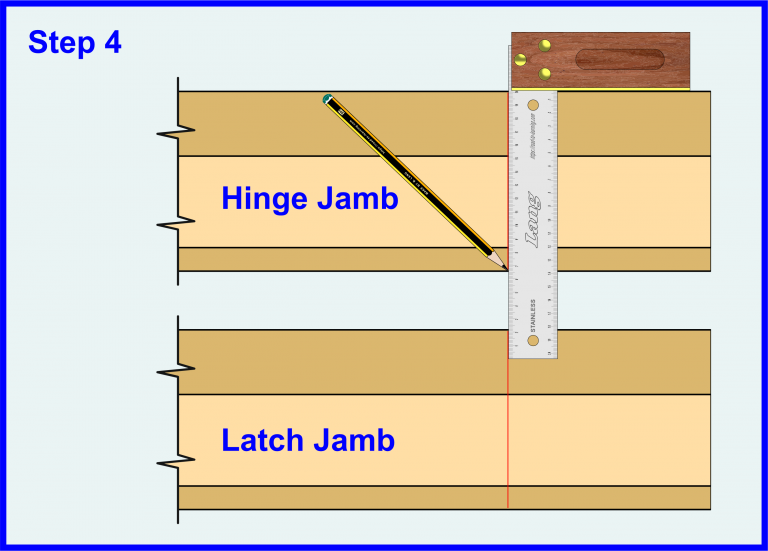

Through Mortice & Tenon Joints Step_04

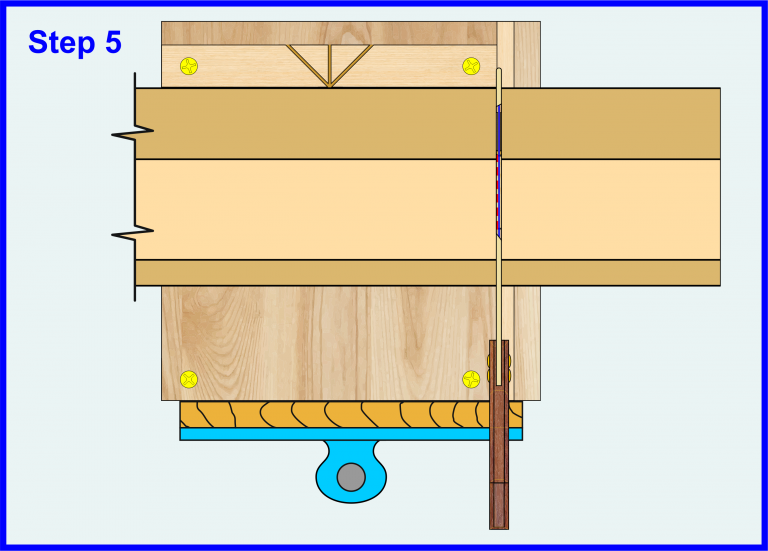

Through Mortice & Tenon Joints Step_05

Place your bench hook into the Workbench Vice and securely tighten ensuring the Bench Hook does not move.

Select a Tenon Saw cut all components for the Door Frame squarely making sure you do two forward strokes cuts on the furthest corner first, then gradually bring the blade down onto the cutting mark on the wayside.

In this series of steps we are marking out the Tenon Tongue for each end of the Frame Jambs, this will also set the size of Mortise using a Mortise Gauge.

Place your Frame Jamb into a workbench vice vertical and secure, using a Try Square place the stock of to Try Square against the Back Jamb.

Move Try Square in line with the start of the recess in the back jamb, then striking line straight across this is your first Edge Cheek

By transferring the mark to all face sides will help you to cut squarely with a hand saw.

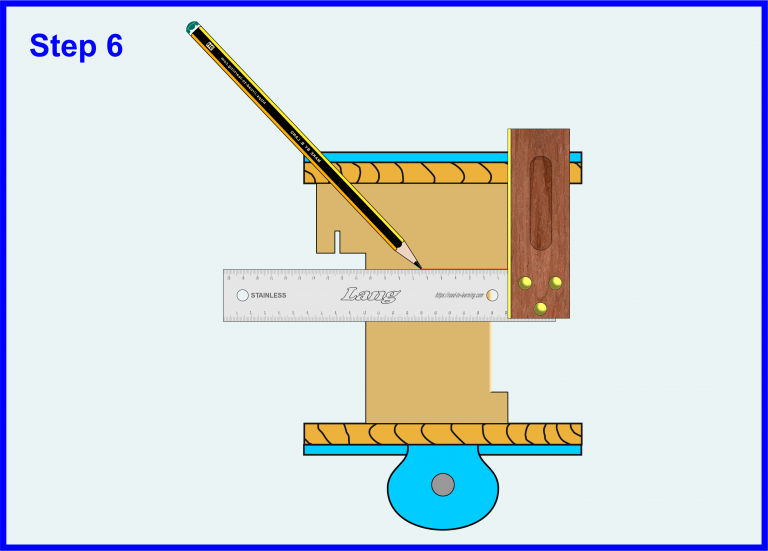

Through Mortice & Tenon Joints Step_06

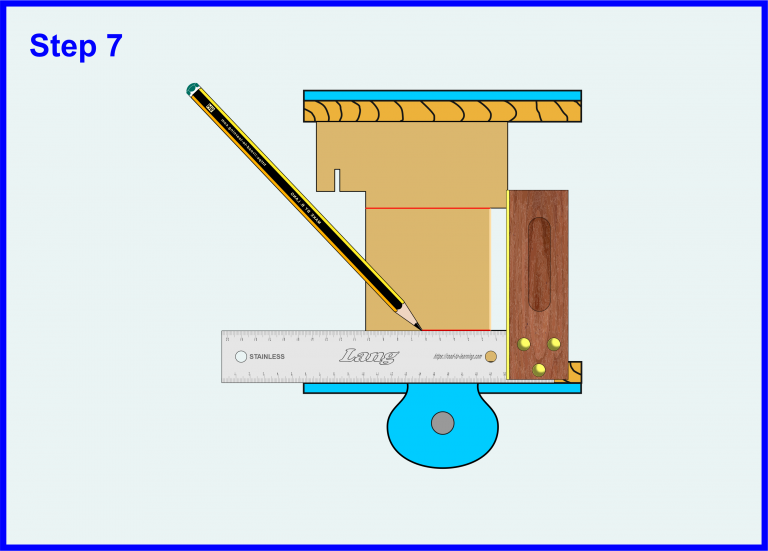

Through Mortice & Tenon Joints Step_07

Keeping a Try Square against Frame Back Jamb then striking line straight across this is your second Edge Cheek.

Using one of the edge cheek marking lines divided by four, then set your Mortise Gauge Pins to the first marks from both ends.

Your Mortise Gauge is now set for your Tenon Tongue and Mortise size, when setting the size of the mortise, you must ensure that the surrounding timber for the mortise must Not be less than 50% of the Face Area.

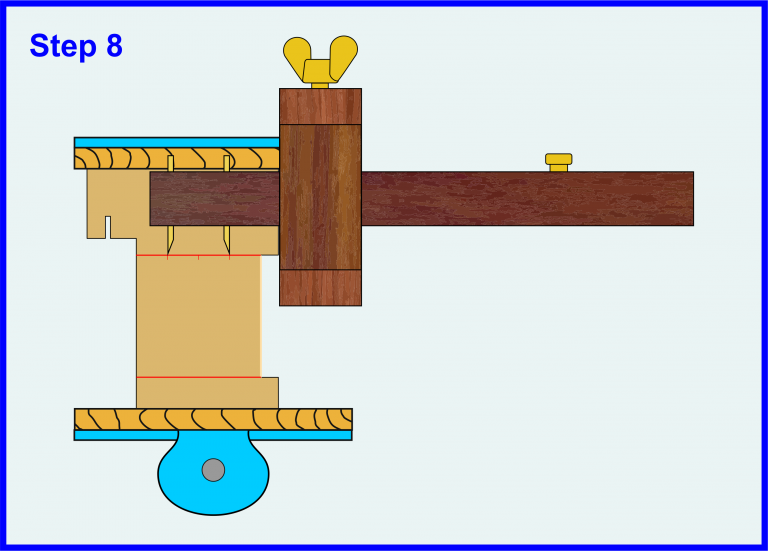

Through Mortice & Tenon Joints Step_08

Through Mortice & Tenon Joints Step_09

Place the Mortise Gauge pins to one edge of the Frame Jamb then striking lines across the face to the opposite edge this will create your Tongue Face Cheeks.

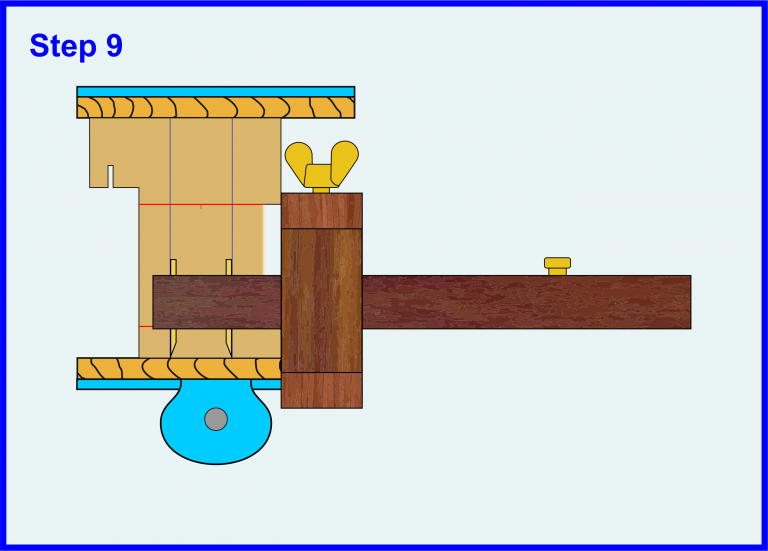

Repeat Step 6 to Step 9 for each end of the Frame Jambs, and remember to use the Fence of the Mortise Gauge on the Back Jamb when marking otherwise, your markings will not line up.

Place the jamb in workbench vice securely upright, place the stock of the tri-square against the face of the jamb.

Strike soldiers mark to the same depth as indicated in Step 10, this will be the depth of the tenon tongue.

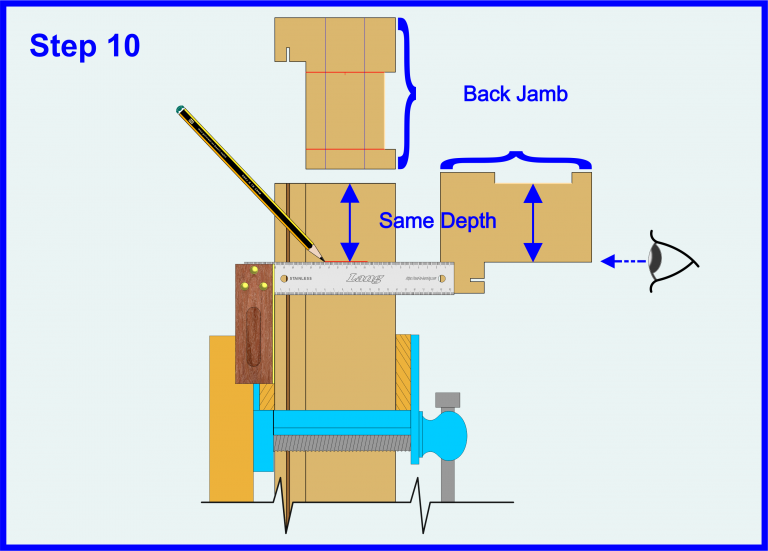

Through Mortice & Tenon Joints Step_10

Through Mortice & Tenon Joints Step_11

Continue the faced cheek mark to Soldiers Mark using your Mortise Gauge, double check that the mortise gauge pins are set correctly to the width of the Tenon Tongue.

To highlight the marks made by the Mortise Gauge simply use a pencil mark inside the grooves.

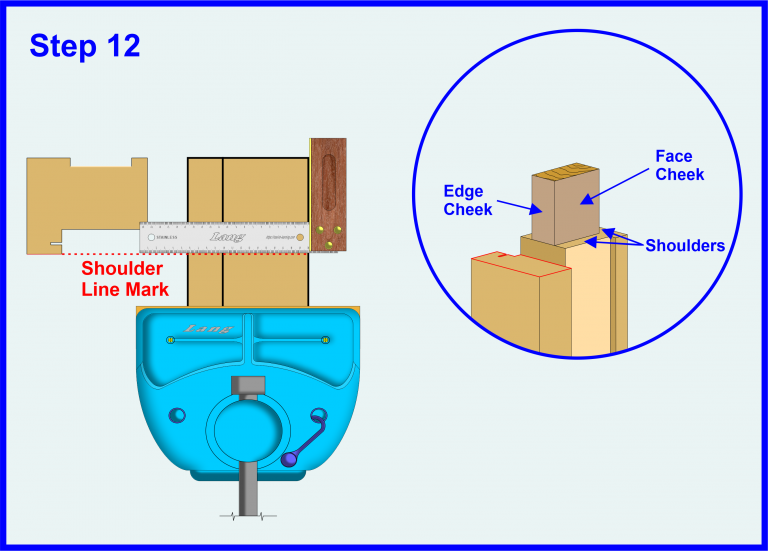

To ensure the Header fits correctly you need to remove additional area on the face jambs on the right and left sides of the Frame Jambs.

This will enable the top of the Header to be level with the top of the Tenon Tongue.

Through Mortice & Tenon Joints Step_12

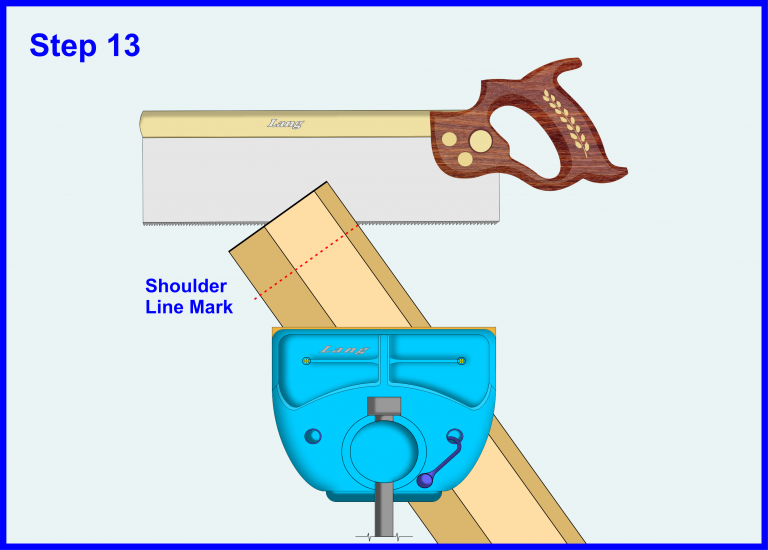

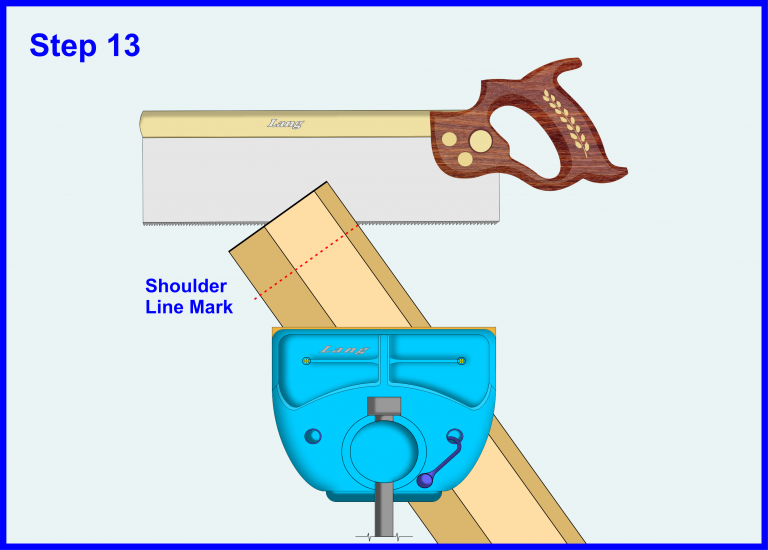

Through Mortice & Tenon Joints Step_13

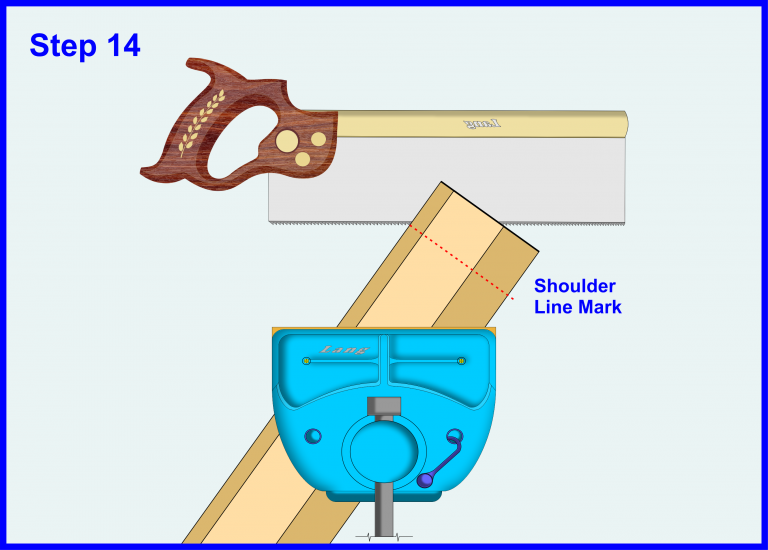

Place the Upright member securely in workbench vice at approximately 45°, Tenon Saw should be kept horizontally when cutting and cut down just short of the Soldier Mark and inside the waste area.

Removed the upright member and rotate to 180° and re-secure it in the workbench vice and repeat the previous step.

Through Mortice & Tenon Joints Step_13

Through Mortice & Tenon Joints Step_14

Removed the upright member and rotate to 180° and re-secure it in the workbench vice and repeat the previous step.

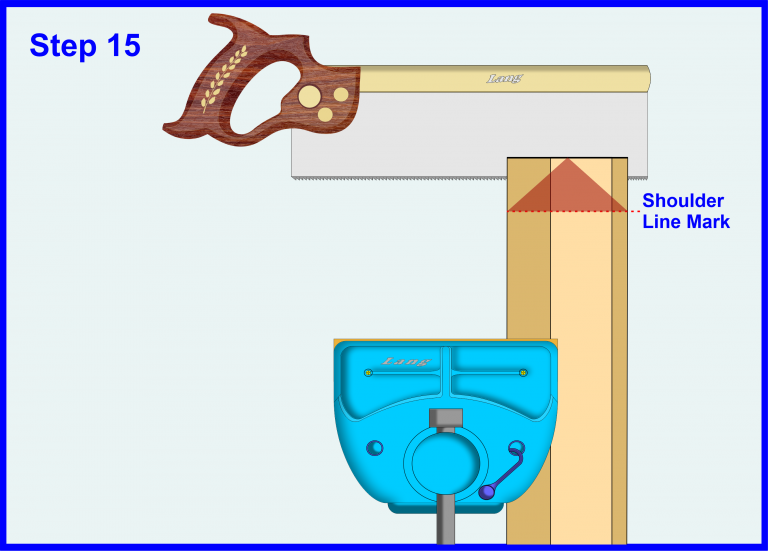

The final part of cutting the cheek is to set the upright member vertically in the workbench vice and cut the shaded final triangle using the tenant saw horizontally.

Through Mortice & Tenon Joints Step_15

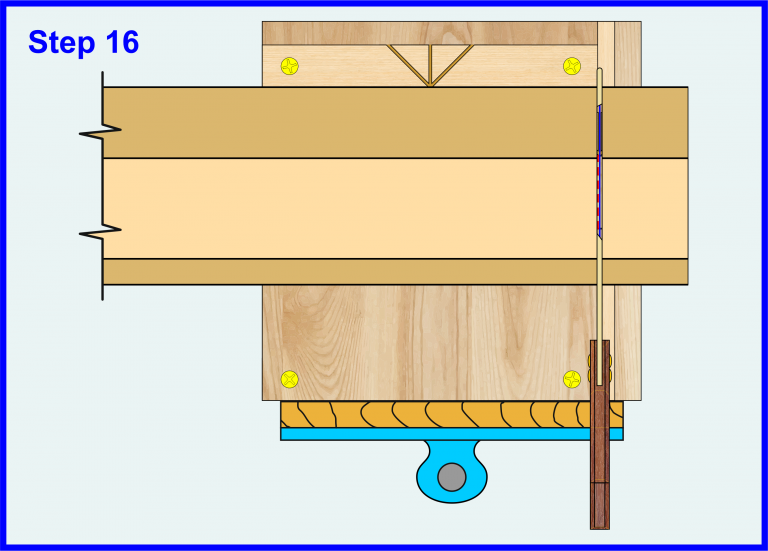

Through Mortice & Tenon Joints Step_16

Set up your Bench Hook into a Workbench Vice securely, place the jambs squarely against the Bench Stop and cut all shoulder lines down to the Face and Edged Cheeks using a Tenon Saw

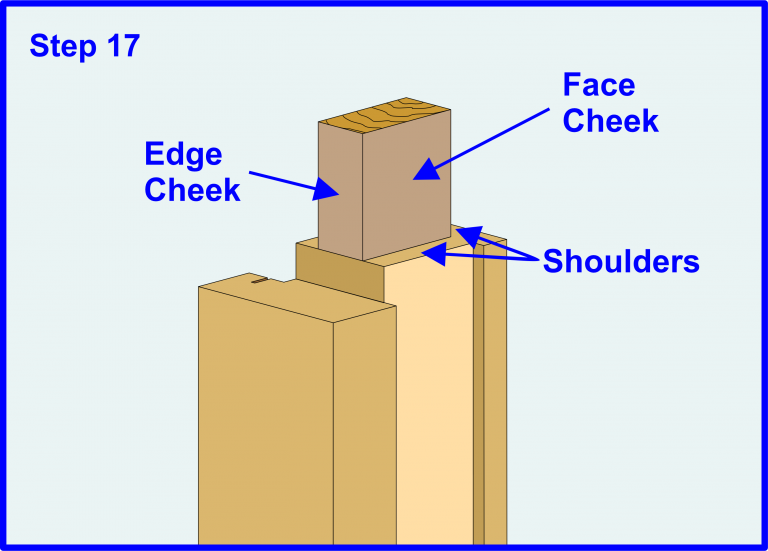

On completion of Step 16 you should have Edged and Faced Cheeks with three Shoulders at the same level and the other stepped down to receive the Header.

Through Mortice & Tenon Joints Step_17

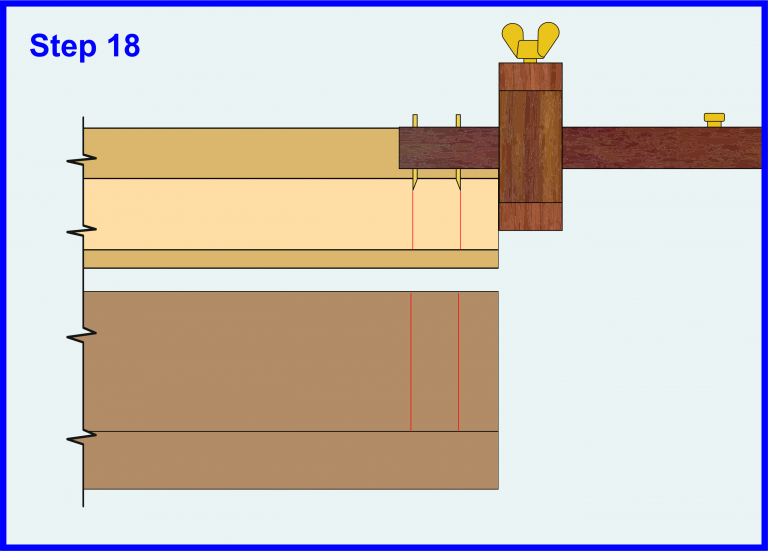

Through Mortice & Tenon Joints Step_18

Hopefully, you haven’t moved your pins on the mortise gauge, double-check that they are still the same width as the Tenon tongue.

Mark the position of the mortise by placing the mortise gauge fence against each and of the Header and Cill, to mark the Face Cheek Lines.

To mark the position of the Edge Cheek Lines on the Cill and Header, adjust the mortise gauge pins on the Back Jamb recess so that the pins are in line with the recess cheeks.

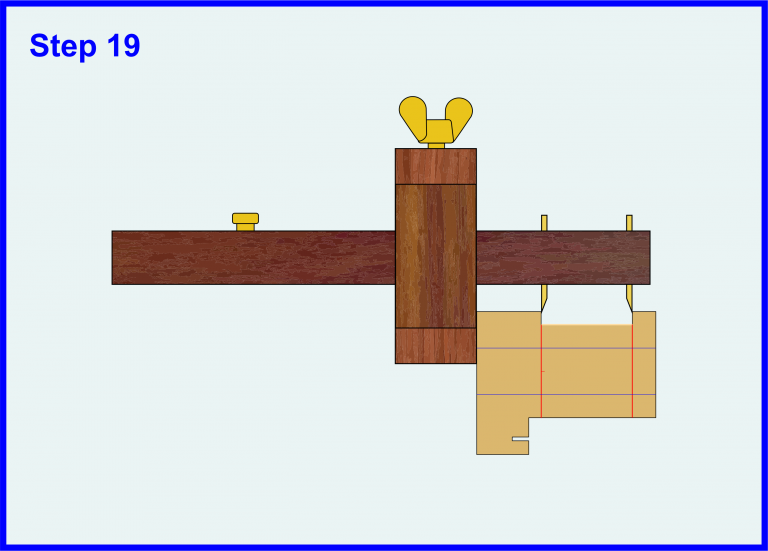

Through Mortice & Tenon Joints Step_19

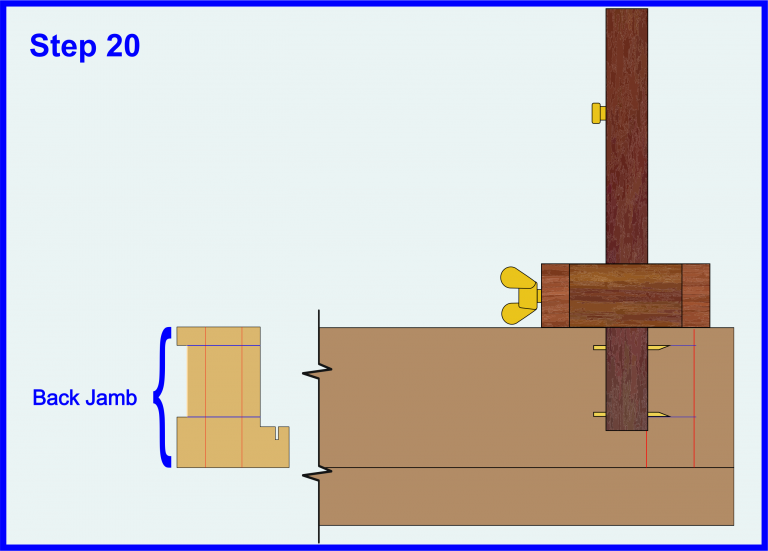

Through Mortice & Tenon Joints Step_20

Now you have set the mortise gauge for the edge cheeks simply mark the Cill and Header, highlight marks if you wish by a pencil mark inside the groove

The process of removing the waste material inside the mortise is the same for the Header and Cill.

Place each component vertically in a workbench vice securely, fixed without bruising the wood.

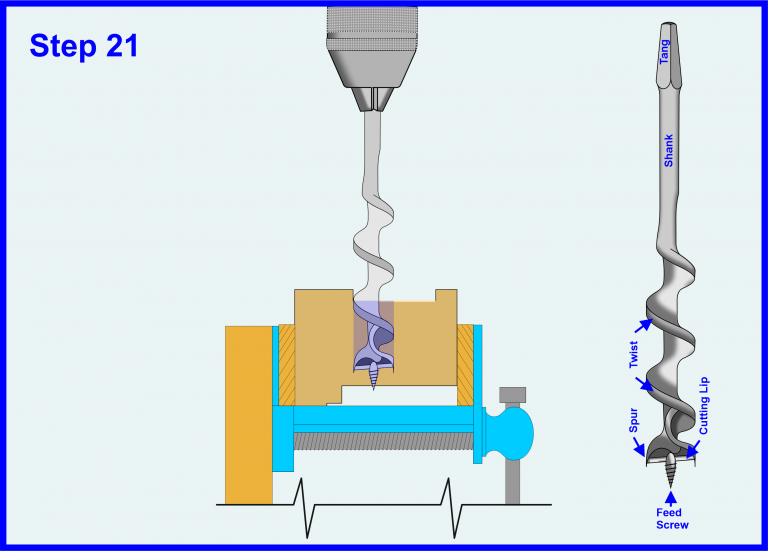

You need to select a Bit Auger which is slightly smaller than the width of the Tenon Tongue, placing the feed screw in the centre of the Through Mortice.

Using a Hand Brace vertically, drill out the waste material until the feed screw is just appearing on the bottom surface.

Through Mortice & Tenon Joints Step_21

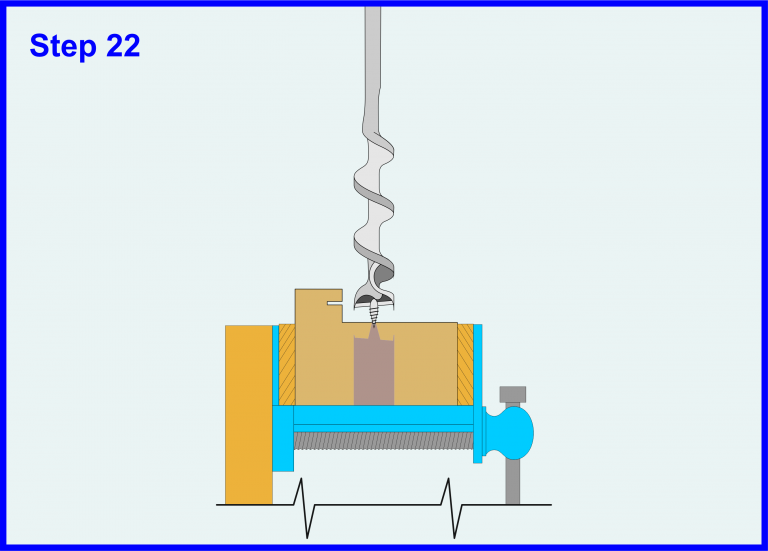

Through Mortice & Tenon Joints Step_22

Rotate the component 180° and place back in the workbench vice securely, then carefully place the Feed Screw into the whole which was previously made.

Remembering to keep Bit Auger vertical and complete the drilling process, you will need to repeat these steps maybe one or two more times to remove the waste material from the Through Mortice.

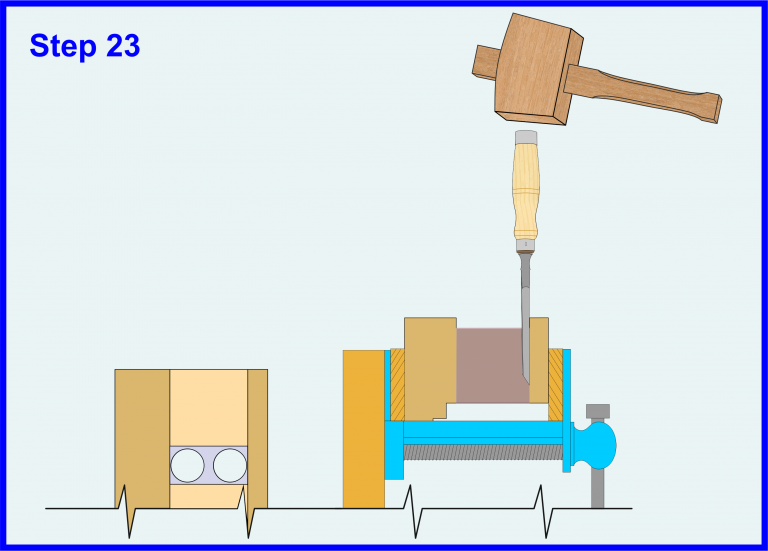

To complete the Edge and Face Cheeks of the Through Mortise you will need to use a Mortise Chisel to remove the waste material, ensuring that you remove small slices working back to your Edge and Face Cheek Marks.

Remember only chisel halfway down inside the Through Mortise on all sides, then you need to remove the component and rotate 180° and repeat the process this will ensure you do not do any breakouts on the surface

Through Mortice & Tenon Joints Step_23

The first step is to clean and degrease the surface completely before you start doing any sanding.

Dry sanding produces a lot`s of dust and you need to wear a suitable safety mask, the dust must be removed by vacuum or with a tacking cloth preferably both to ensure there are no dust particles.

Additional information on sanding, click on the links below

Wet And Dry Sanding

Sanding In Hard-To-Reach Places

Sanding Blocks Or Hand Sanders

What Is Glasspaper

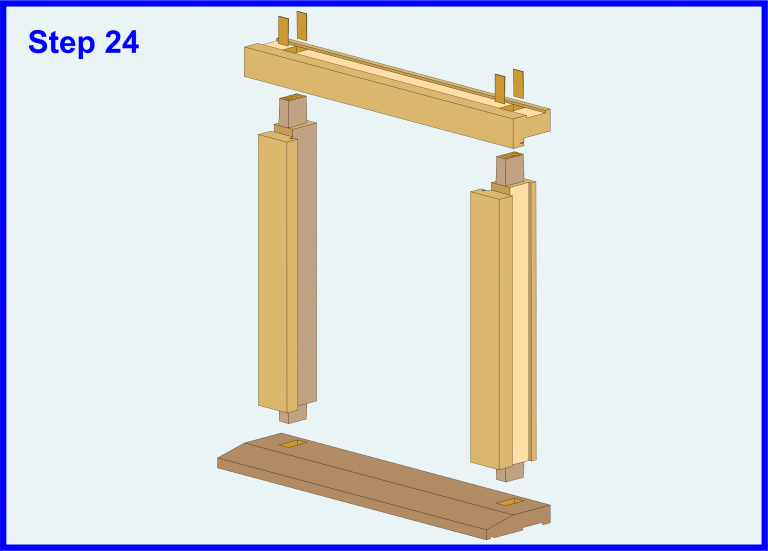

Through Mortice & Tenon Joints Step_24

use a waterproof wood glue like Polyurethane glue for all exterior adhesive applications above the waterline.

Apply the wood glue by brush or stick ensuring that you do not glue right up to the edges of the Mortice & Tenon Joints.

After assembling your assessment frame piece ensure you remove any excess glue which comes out of the Mortice & Tenon Joints.

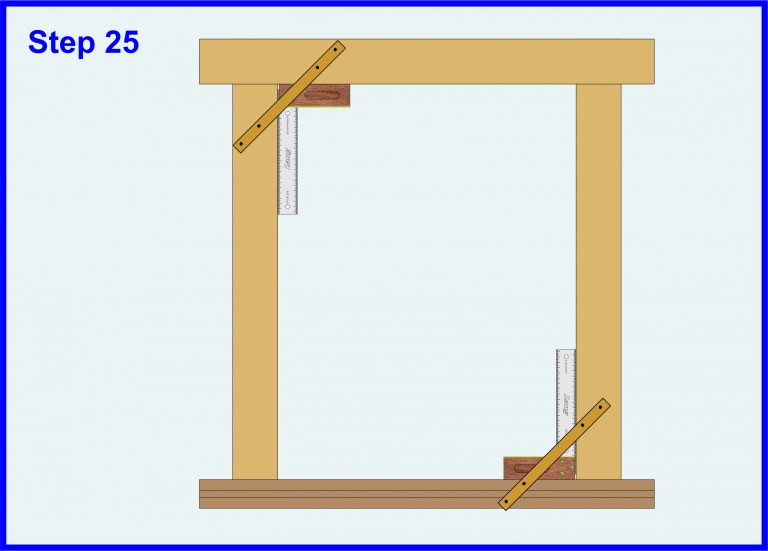

You have now assembled the assessment framework you need to check for squareness, using a Try Square place it against the Header so the blade runs down one side of the Jamb.

I adjust the jamb so it’s parallel to the Try Square Blade, use scrap pieces of timber to pin into position.

The next step is to test for squareness on the opposite jamb you need to place the Try Square against the cill and adjust the jamb so it is parallel to the try Square blade, then pin into position as above.

Through Mortice & Tenon Joints Step_25

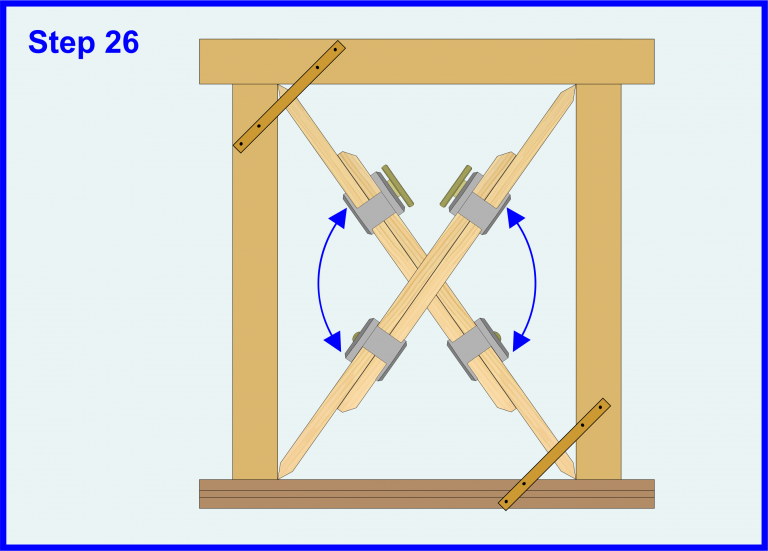

Through Mortice & Tenon Joints Step_26

An alternative method is to use a Tape Measure and measure from one corner to the opposite corner diagonally, and then compare that distance to the opposite diagonal measurement.

The two distances should match exactly, or use a Pinch Sticks or Squaring Rod and adjust it so it fits in the diagonal position from corner to corner, then rotate to test the opposite corner.

For additional information on Pinch Sticks or Squaring Rod, Click on the link with low

Once you are happy with your practical assessment make sure your working areas are clean and tidy, plus all tools are put away before asking your assessor to mark your assessment piece.

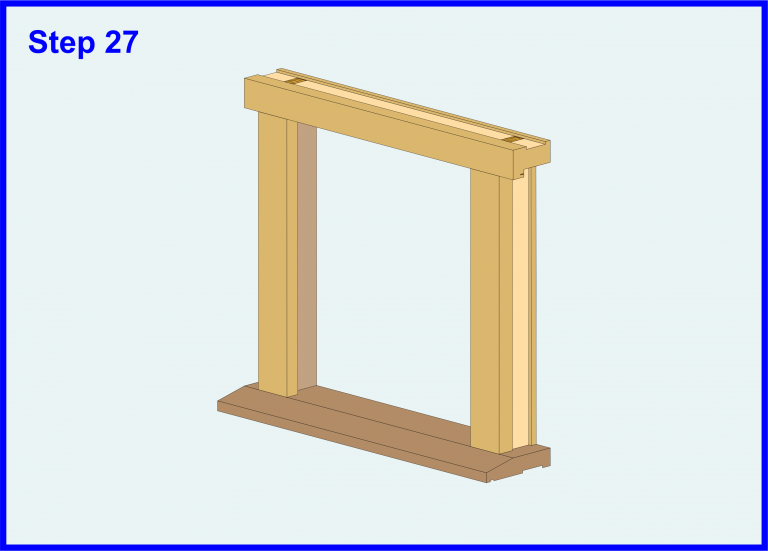

Through Mortice & Tenon Joints Step_27