Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Aim

Learning outcome

The learner will:

Assessment Criteria

The learner can:

There are two main types of wood hardwoods and softwoods, example below is European Redwood which is a softwood.

Redwood Timber

When selecting timber for your halving joint make sure it hasn’t got the following defects

Defect and Cause

Shrinkage: Occurs due to the timber losing moisture

Splits: Occurs when wood shrinks and becomes dry

Shakes: Cracks found in timber

Knots: Broken off or cut branches that reveal exposed wood

Fungal attack: Plant organisms known as fungi live on and attack the timber causing it to rot or decay

Bowing: Curvature along the face of a board

Springing: Curvature along the edge of the board where the face remains flat.

Winding: Twisting of the board.

Cupping: Curvature across the width of the board

Avoid using any Wood knots in your selection of timber as knots we can strength of the timber and are difficult to cut and chisel through.

There are two types of PVA glue one is waterproof and the other is none waterproof where waterproofing is not essential.

PVA glue can be used as a high-performance sealer, primer, bonding agent and dust proofer.

good air circulation is needed for PVA glue to cure and dries faster at room temperature, to achieve strong joints you need to have tight joinery and use clamps until the PVA has Cured (dried).

Additional strength to the halving joints can be achieved by using wooden dowels or screws.

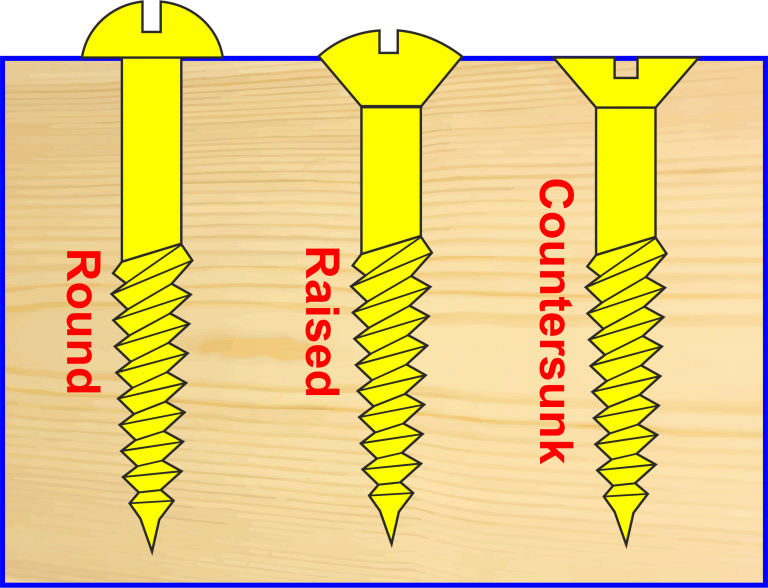

Types of Screw Heads

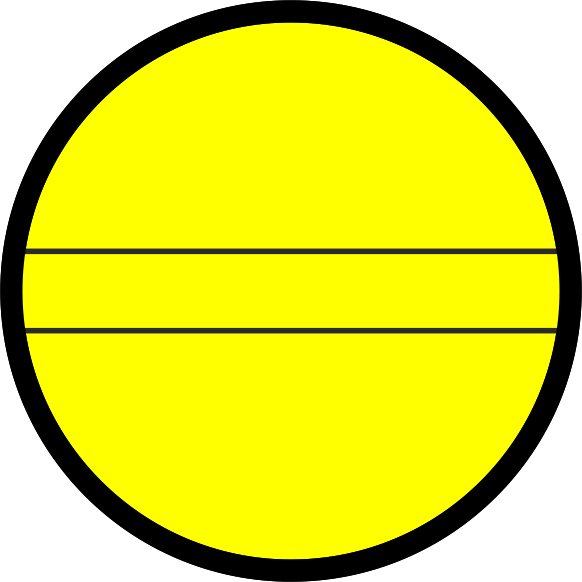

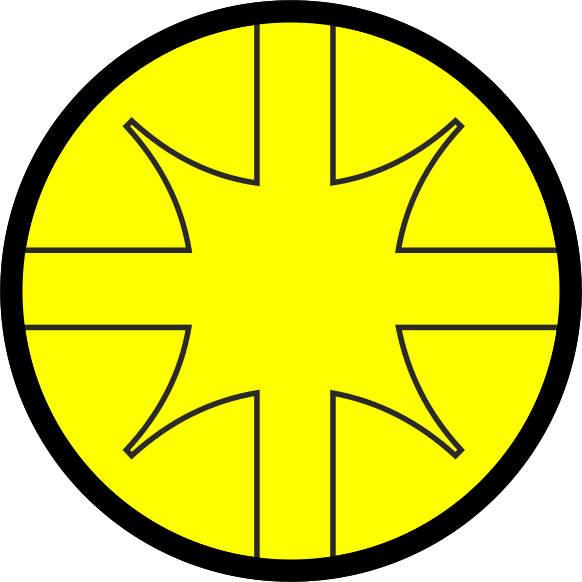

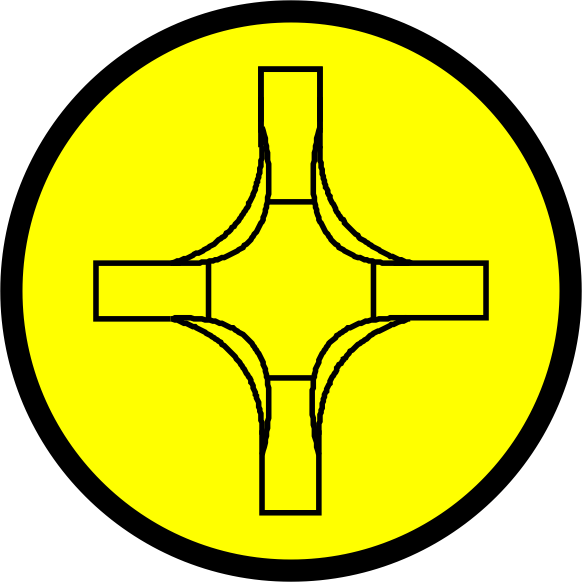

There are three different recesses:

1. Slotted to receive the flat bladed screwdriver

2. Cross shape to receive a Phillips screwdriver

3. Star shape to receive a Pozidrive screwdriver

The screw thread can also vary depending on the type of material into which the screw will be driven, e.g. wood, wood chip.

Slotted Screw Head

Pozidriver Screw Head

Phillips Screw Head

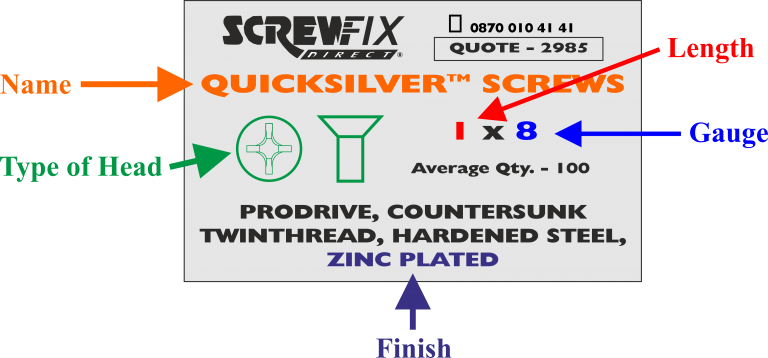

Screws are of particular interest in the way they are sized, the metal they are made from, the variations in shape and the different ways in which the head is recessed to receive the screwdriver blade.

All of these descriptions will be on the label at the end of the box.

The metal used is usually either steel or brass.

Brass screws are more expensive but will not rust.

Finishes to screws include galvanising, black japanned and chromium-plated.

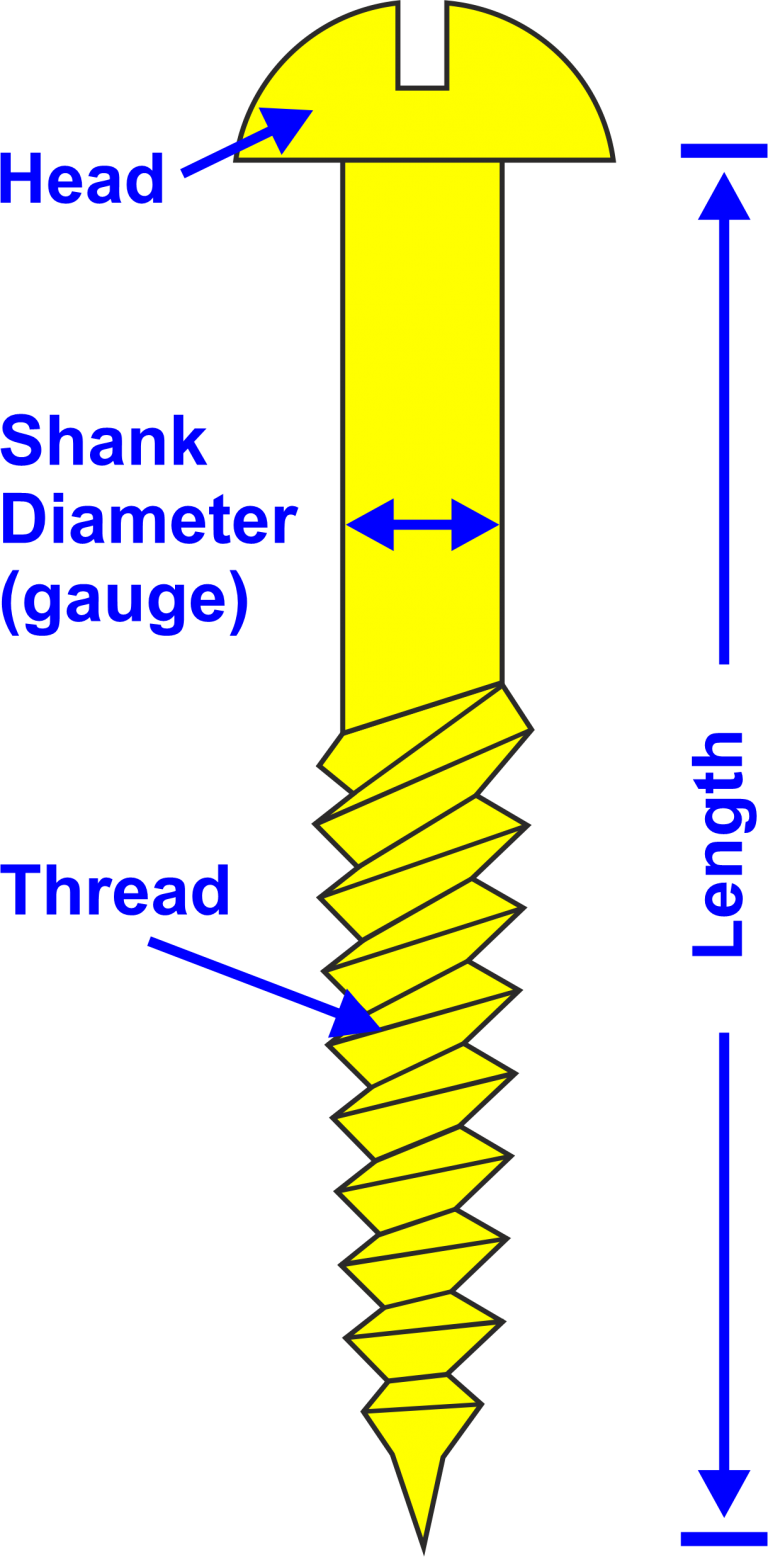

The length of the screw can vary from just a few millimetres to 150 millimetres and more and the length is shown on the box is the amount it goes into the wood.

The thickness of the screw, called the gauge, also varies for each length of the screw and is identified by a number, e.g. 2, 4, 6, 8, 10 etc.

The heads of the screws vary in proportion to the thickness.

Although the construction industry uses metric measurements, screws are often sold with the Imperial measurement shown, e.g. 8 x 25 mm may be marked 8 x 1.

Parts of a Screw

Screws Box