Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

The learner will:

2. be able to set out and build cavity walls.

The learner can:

2.1 use Personal Protective Equipment (PPE) appropriate to building cavity walls

2.2 select the tools, equipment and materials required to build cavity walls

2.3 set up a mortar board and stack the number of bricks and blocks required to complete the walls

2.4 build cavity walls to given specifications

2.5 finish the brick work to given specifications.

The learner will:

3. be able to maintain a clean and safe working environment.

The learner can:

3.1 set up the work area safely

3.2 maintain a clean and safe working area following health and safety guidelines

3.3 clear work area of surplus materials and debris on completion of the jobs

3.4 clean all tools and equipment ready for re-use.

This guidance document sets out the aspects of this unit where the demonstration of skills, knowledge and understanding to the required competence must be assessed.

It indicates where assessment opportunities occur within the work plans, assignments, student’s handbook and question paper.

Each student must work individually to complete all of the practical activities, assignments, completion of their handbook and the unit question paper.

Where team activities are carried out, each student must be assessed in the lead role.

Students must carry out all work activities safely.

Correct PPE should be selected and worn, or used, as appropriate.

There must be no risks to self or others and no risk of environmental pollution.

The following Safety Rules should apply:

1. Before, during and after carrying out any work, the workplace must be clean and tidy to prevent tripping and falling

2. Organise the work and set up tools and equipment

3. Check all equipment is in good working order.

Setting up to carry out your work effectively and efficiently can save time and risk of injury to yourself and others

4. Always wear protective clothing:

Gloves when handling materials and components

Boots in case of impact injury

Mask in dusty atmospheres

Ear defenders in noisy conditions

Goggles to protect eyes from flying debris

Helmets at all times when on a building site

5. Be aware of emergency procedures in the event of an accident:

Who the first aider is

Where the first aid box is located

How to fill in the accident book

Report accidents to the person in charge

6. In the event of fire:

Carry out the correct emergency procedures for calling for help and evacuate the building

Are You In Control

This activity looks at the how bricks and blocks are laid to line in terms of their:

· Bonding

· Accuracy

· Finish

Outcomes

By the end of this activity, students should be able to:

· Mark Out a Gauge Rod for Brick Courses

· Mark Out a Gauge Rod for Block Courses

· Select and Name Correct Tools and Equipment for Laying Bricks and Blocks to Line

· Mix Mortar

· Work Out the Required Number of Bricks/blocks/bats/closers

· Lay Bricks and Blocks to Line and Gauge

· Check That Levels, Face Deviation and Perpends Are Within Allowable Tolerances

· Point Up the Joints on Facework

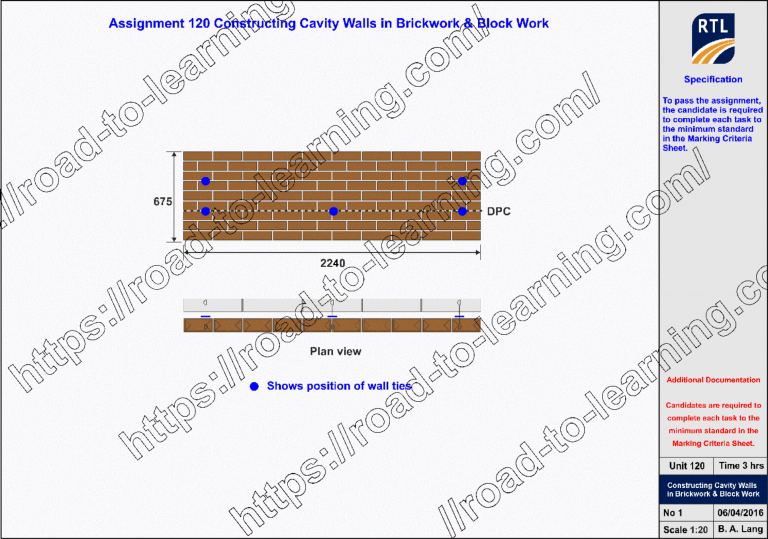

The assessor will ask you if you’re ready to do the assessment, if so you will need to study the working drawing above, to identify and list all the P.P.E., Materials, Tools and Equipment required to

build a Half Brick Thick Wall

Selected of P.P.E.

For additional information on this topic click on the links below:

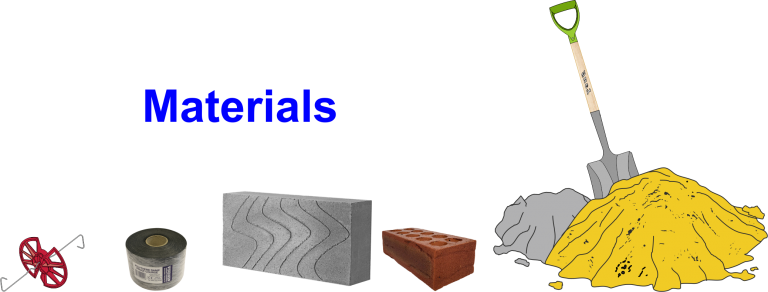

Tools, Materials and Equipment required for Constructing Cavity Wall

The first stage in building a wall is to sweep the assessment area ensuring that you clear away debris where the bricks are going to be laid.

Remembering to use your P.P.E., normally assessment areas in a training centre are very dusty you will need to wet the surface area down with water before using your sweeping brush.

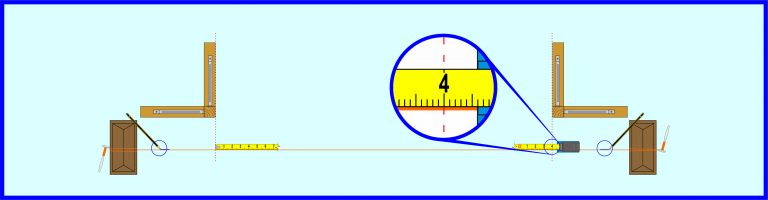

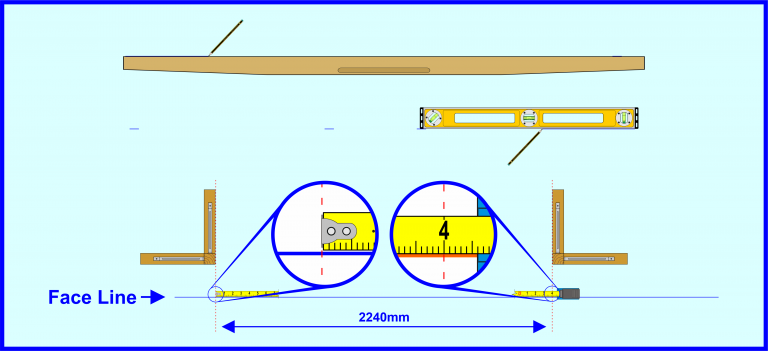

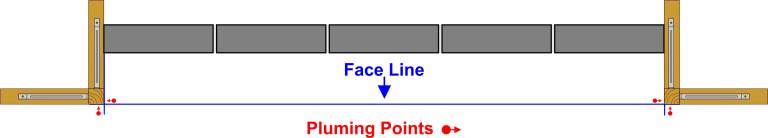

To strike the face line for this assessment you will need two bricks, a line and pins and a pencil.

Unwind a length of string line sufficient to span the assessment area plus the profiles, wrap the string line around brick 2 to 3 times then run a taut string to the length of your profiles and face line.

Using a pencil marks the start and end of the string line, using a long straight edge placing the edge onto both marks, complete the face line.

If you haven’t got a long straightedge you need to do two additional marks from both ends to the length of your level and strike the line between both marks at each end.

Now you have marked the face line you need to mark the start of the wall and the end of the wall on to your face line, ensuring you have enough face line for your profiles on each end.

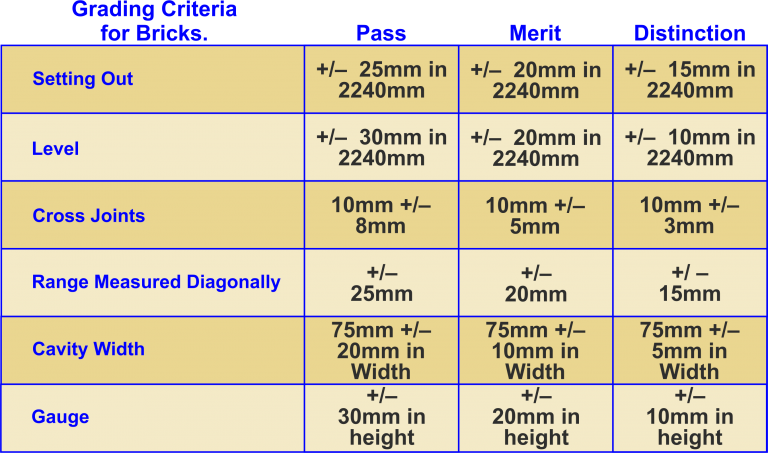

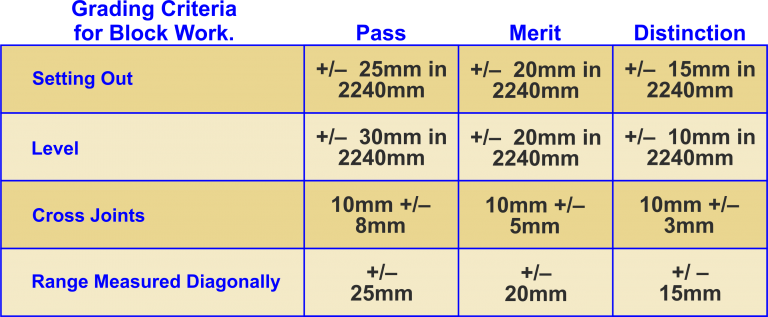

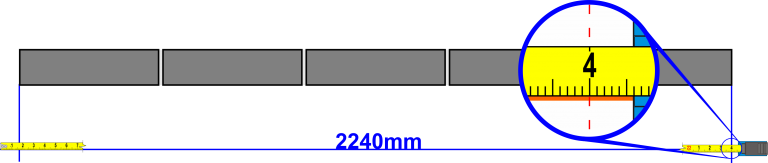

Grading Criteria for Setting out Blocks & Bricks between Profiles is:

Pass +/– 25mm in 2240mm.

Merit +/– 20mm in 2240mm.

Distinction +/– 15mm in 2240mm.

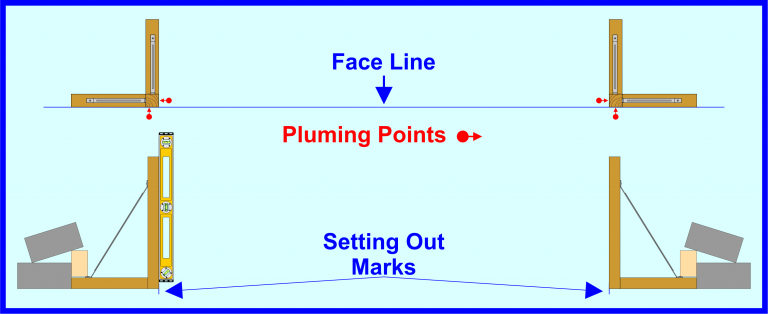

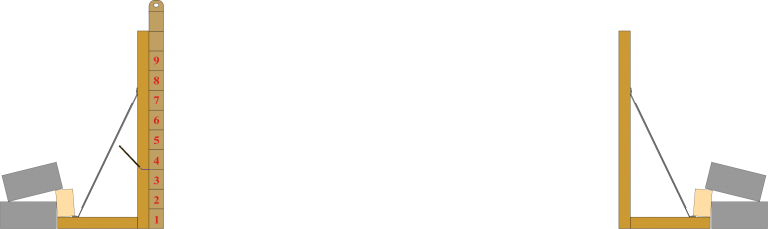

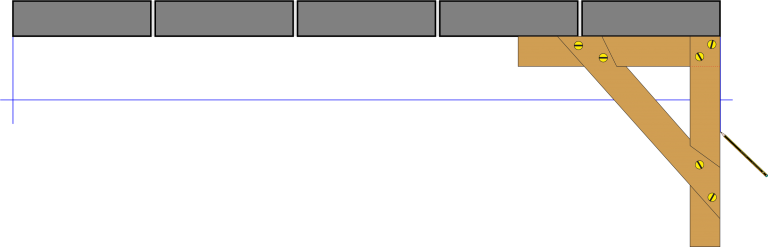

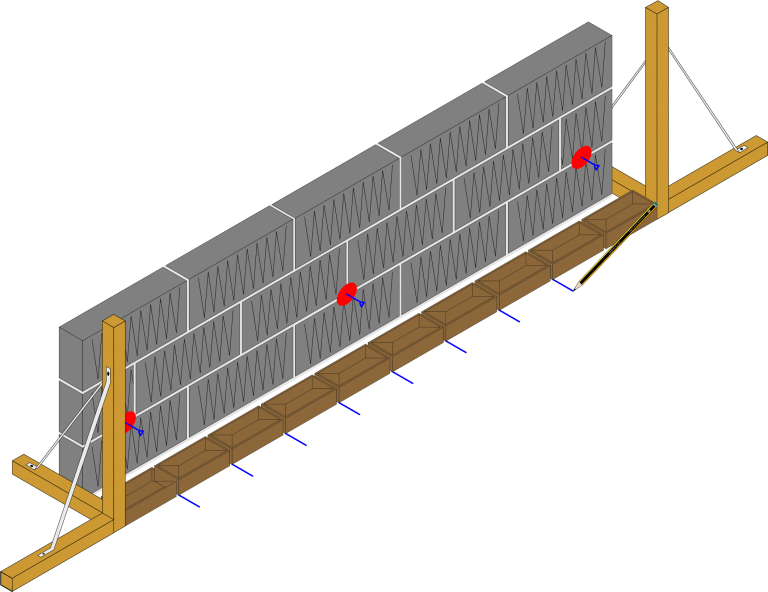

You need to check the profiles for any damage and they have sufficient upstand to carry out your assessment to the required courses of bricks.

Each end of your half brick wall requires a profile with the upstand of the profile placed on the marks previously made and in line with your face line.

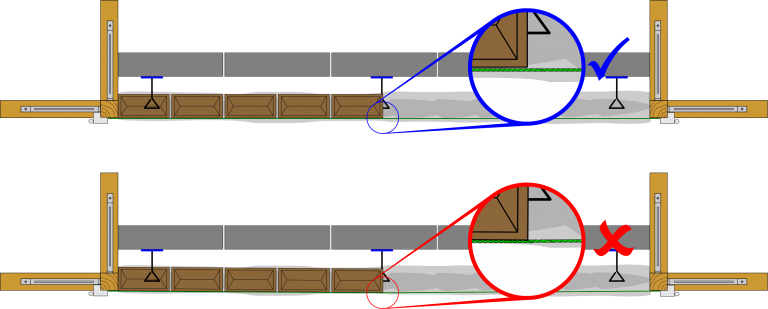

Before you secure your end profiles with blocks you need to check for plum the face edge and stop end of the wall which is indicated in the image.

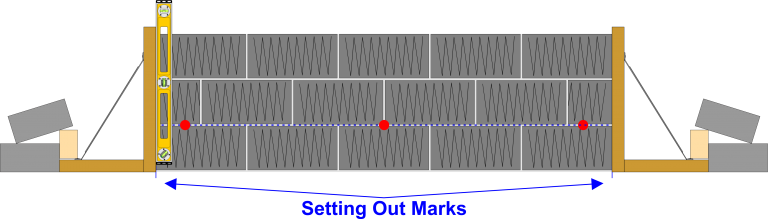

When setting out a building is good practice to place a course of blocks to gauge along the length of the wall in Dry Bond which is laying bricks without mortar on the bed and perp joints to the co-ordinating size of 450mm which is the working size of a brick with perp joint.

Generally, architects will design Buildings with the aid of a Blockwork dimension table to minimise cuts during construction.

For additional information on this topic click on the links below:

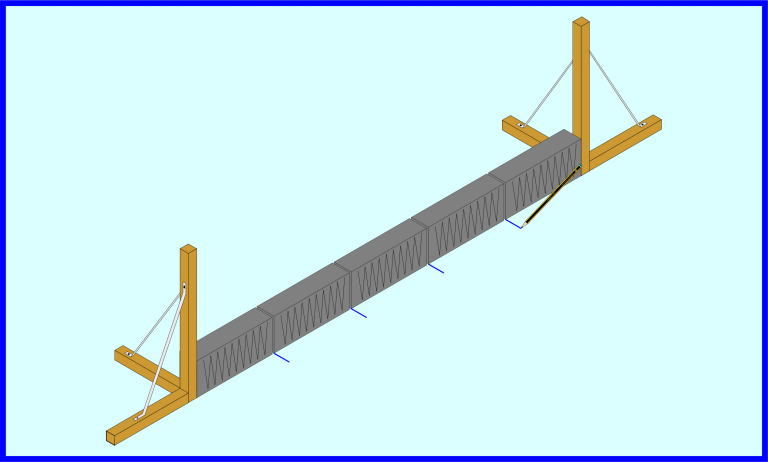

Cavity wall consists of two walls known as the inner leaf and external leaf

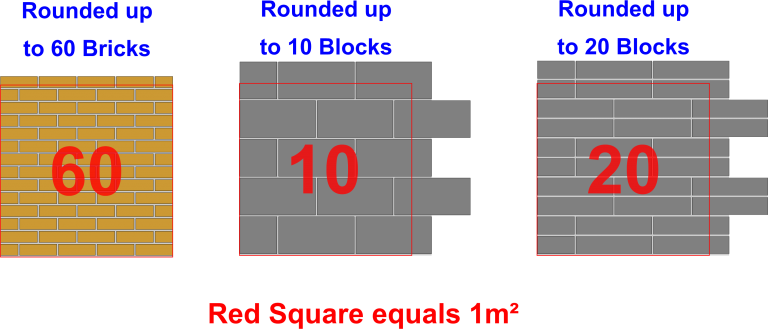

The inner leaf of lightweight blocks require 10 blocks 1m², if the blocks are laid flat you require 20 blocks per 1m².

The outer leaf ½ brick wall which requires 60 bricks per 1m², one brick wall has 120 bricks per 1m², normally a garden walls.

For additional information on this topic click on the link below:

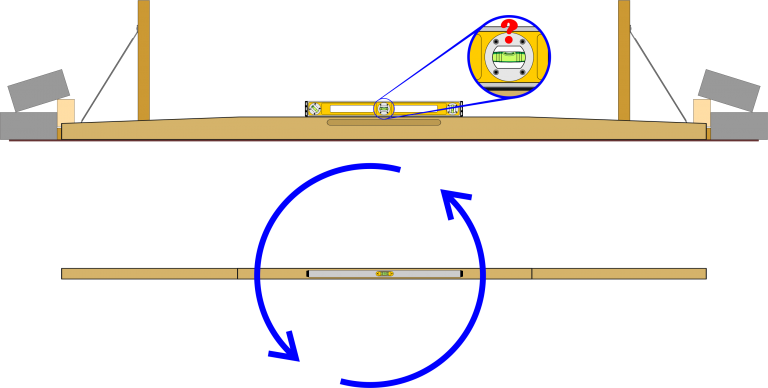

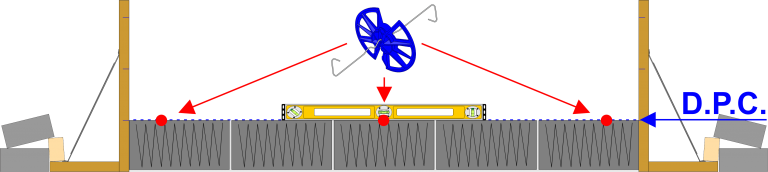

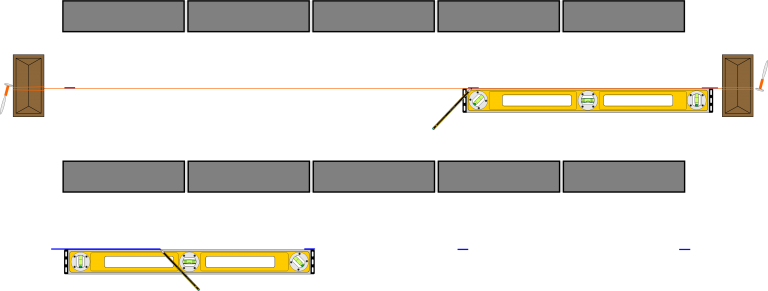

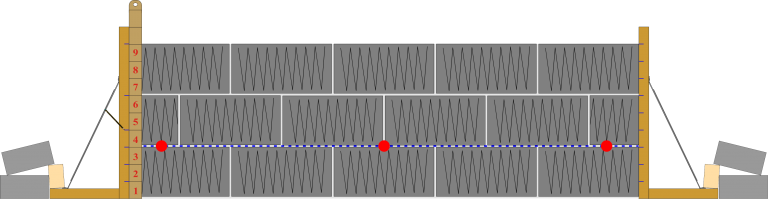

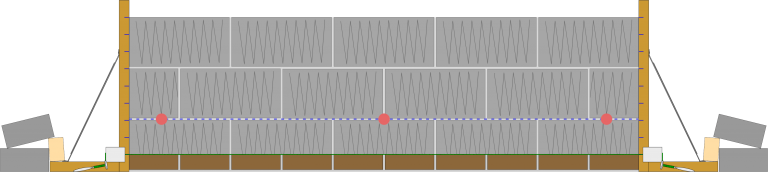

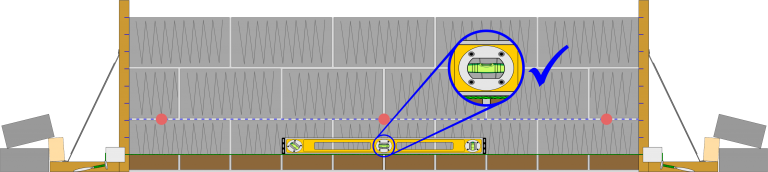

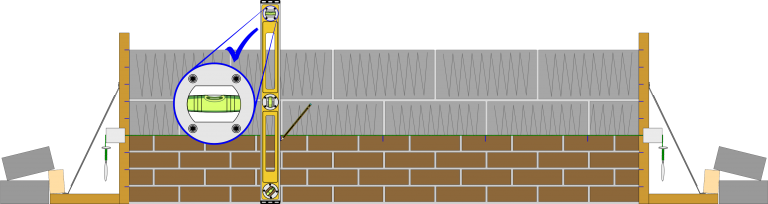

You need to check your assessment area for level between the profiles, this ensures that your gauge rod is placed on the highest point in your assessment area.

This will ensure that you have a minimum of 10mm mortar bed.

When checking levels with a spirit level and straight edge remember to reverse the spirit level and straight edge to double-check the accuracy of the level.

For additional information on this topic click on the links below:

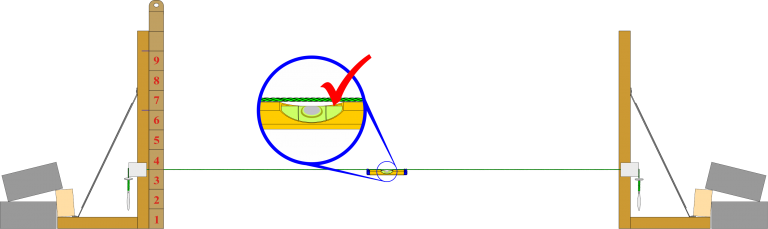

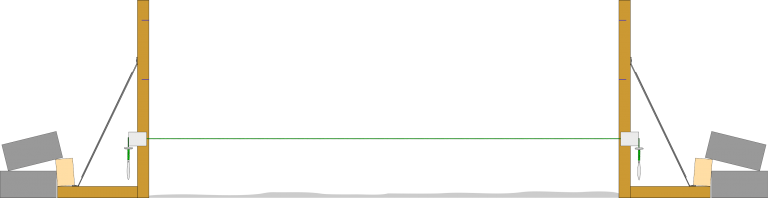

Corner blocks are used in preference to pins as they eliminate making good pinholes and they are less likely to disturb the corner.

The function of a corner block is to hold the line taut and at the correct height so that the bricks or blocks can be laid to the level.

Corner Block are used in pairs and they come in different materials and shapes.

Previously you use a Straight Edge and Level to work at the highest point between the two profiles placed the gauge rod against the profile which is the highest point on the assessment area.

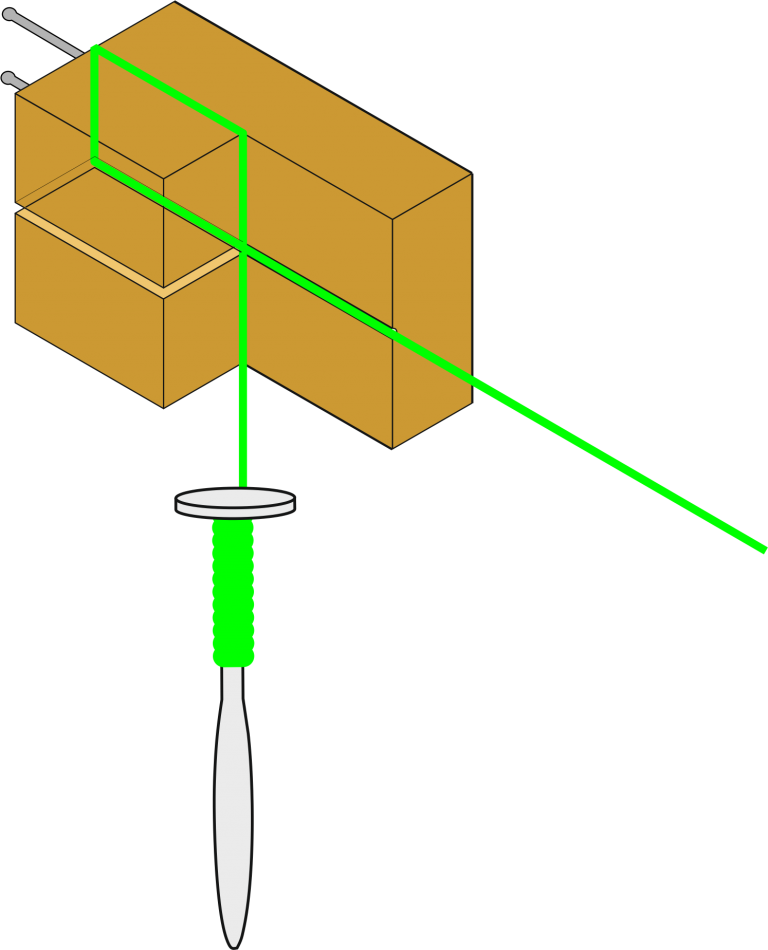

Transfer the first-course Block (3 Courses of Bricks) from your gauge rod mark onto the profile using a pencil this will ensure that you have a minimum of 10mm bed joint.

Fix corner blocks at each end and pull the line so that it is taut this will enable the string line to support the Line Level to sit on the string line without creating the line to sag when checking for level.

Attach the Line Level to the middle of the line using the small hooks on the line level, if you find that the String Line is not level, then raise or lower the corner block opposite end to your gauge marked profile.

For additional information on this topic click on the links below:

Brick Lines

Line Pins And Corner Blocks

For ease of mixing the area should be flat, hard, e.g. Concrete, mixing board, and free from dust and other debris.

It is important that stones are not mixed in with mortar as these can affect the true laying of bricks and blocks.

Mortar will stain the surface over which they have been mixed even when the area is washed down after the mixes are used.

An area should be chosen where stains do not matter.

If possible, the area should also be close to where the work is taking place and/or near the stored materials.

The area should also be large enough to enable you to use all the tools and equipment Safely.

For additional information on this topic click on the links below:

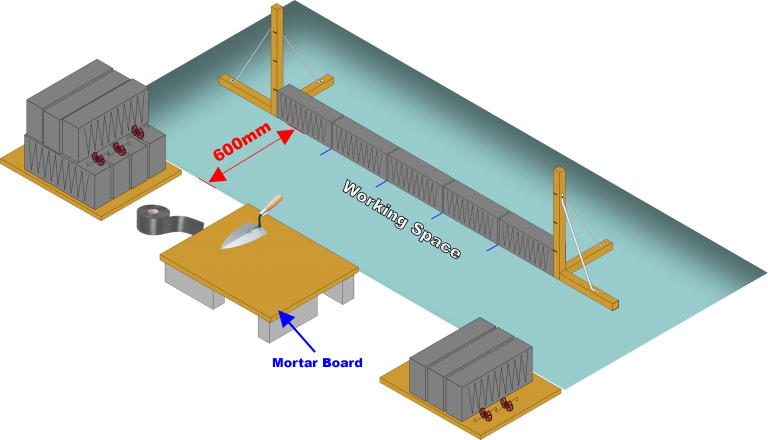

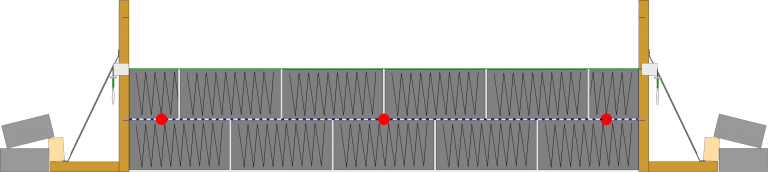

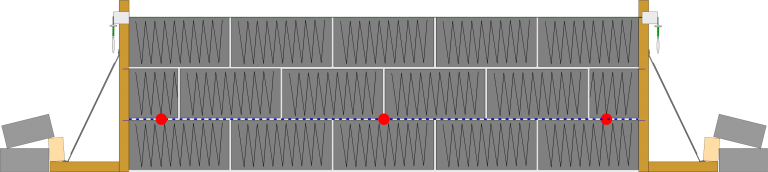

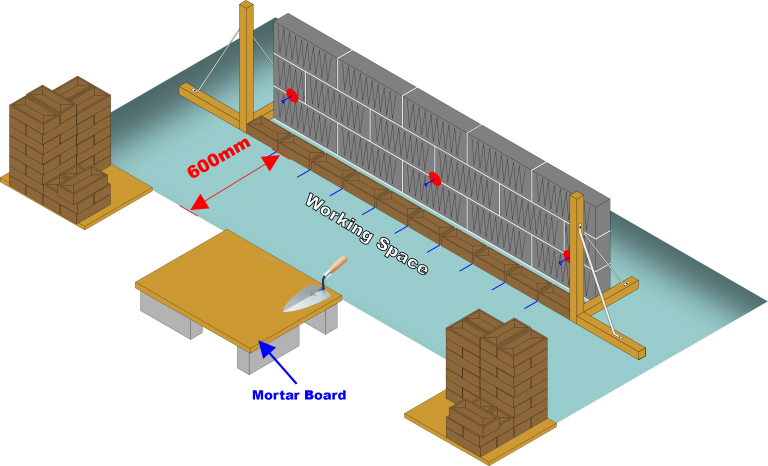

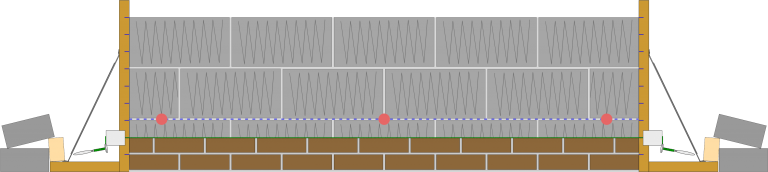

loading out the blocks and mortarboards alternatively running along the face of the wall Leaving 600mm for the working area from the face of the wall to the materials.

Blocks stacked on edge and with the face of the block away from the mortarboard

If you’re on the first lift which is from horizontal dpc level then you need to think about putting boards underneath of the brick stacks or blocks, to stop them absorbing water from the ground or contaminating the bricks or blocks.

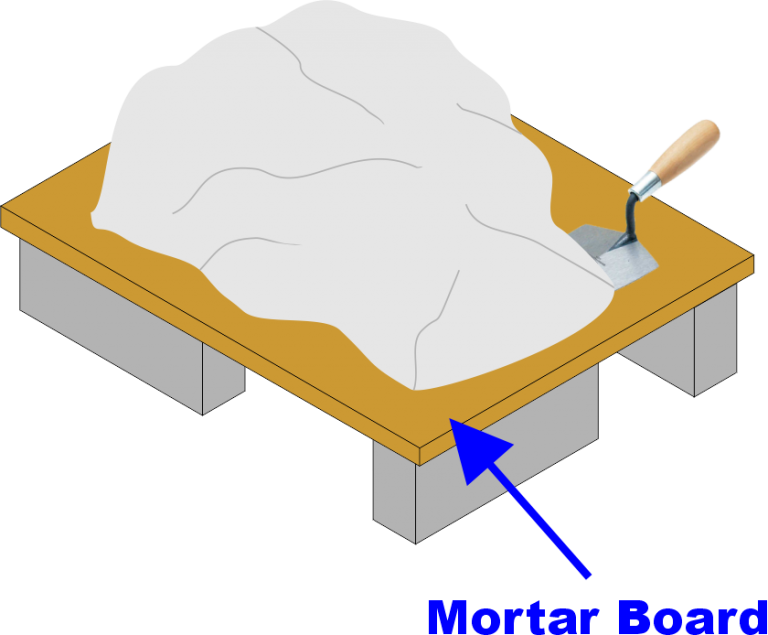

Mortarboards normally 600x600mm and are placed onto concrete blocks on edge and the boards are whetted down so they don’t absorb all the moisture from the mortar mix which will weaken the mix and workability.

Blocks which are adjacent to the mortarboards must have the face of the brick facing away from the spot board this ensured that no mortar is splashed onto the face of the brick.

At the end of the day, all mortarboards are cleaned and placed on top of the brick or block stacks to protect them from the rain.

For additional information on this topic click on the links below:

Now you set up your workstation and you’ve mixed up your mortar to the right consistency, wet the mortarboard before loading mortar onto the centre of the board.

Some bricklayers like a full mortar board enabling them to cut into the mortar and pick up the mortar in pasty-shaped.

Alternative methods is to use your trowel and pull away a small amount of mortar in a sawing action, roll the mortar along the board until it looks like a sausage.

Using the edge of the trowel to slide under the mortar in a forward motion to pick up the mortar.

For additional information on this topic click on the links below:

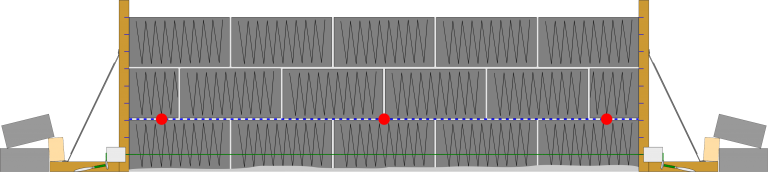

Placed each corner block onto the end profiles making sure that the line is taut, adjust each corner block so that the line is the same height as your gauge rod markings.

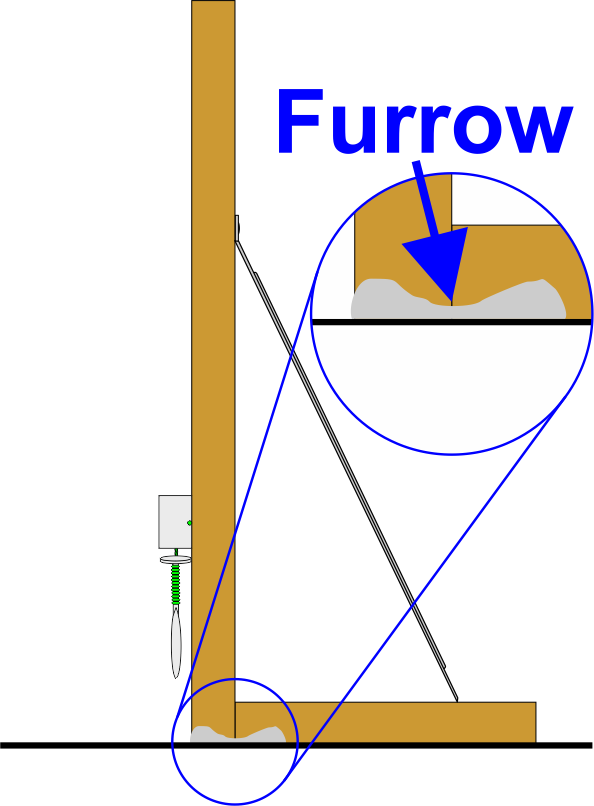

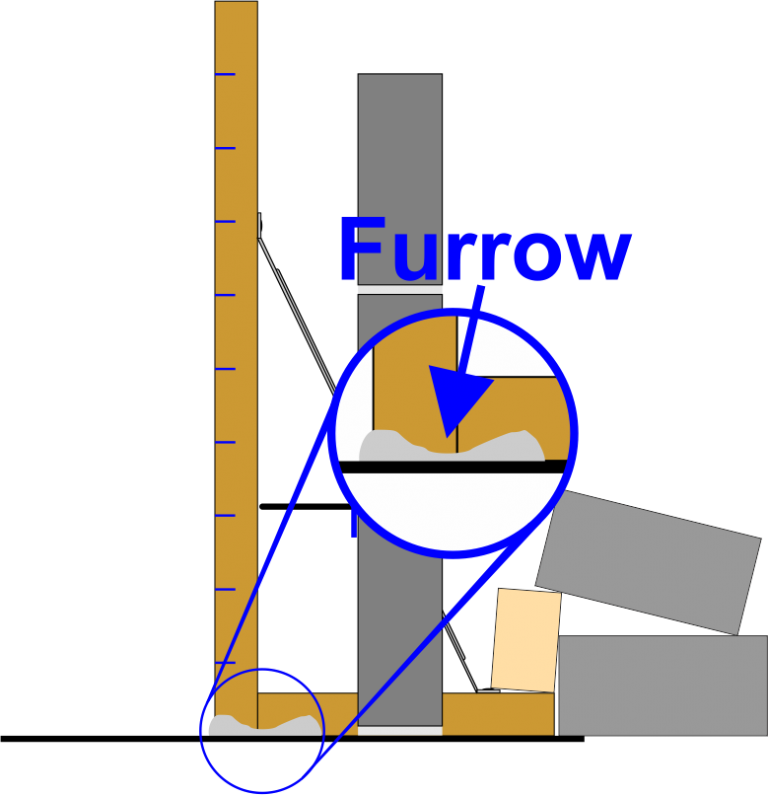

Standing in your working space pickup a trowel of mortar and with the trowel just off the ground, swing your arm back towards yourself, turning your wrist, allowing the mortar to slide off the trowel along the string line this is known as the bed.

To complete this process using the point of the trowel make a v shape indent which is known as a furrow to the length of your mortar bed.

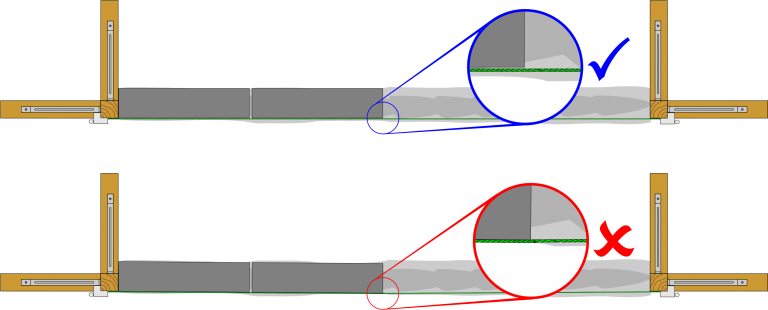

The first block should be laid to line and the face of the block should be set back slightly from the string line, otherwise you will foul the line which will cause a bowl in the face of your wall and be out of plumb.

Buttered Up the Wrong Way

The next block should be ‘buttered up’ just like you would do with a brick.

The trowel should be used to cut away excess mortar that is squeezed out from underneath or in between the blocks.

Buttered Up the Right Way

Before starting in the next course of blocks double-check that your course work is level.

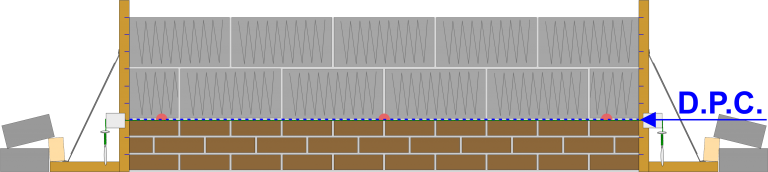

Flexible D.P.C. is laid on to a fresh bed of mortar approximately 5mm thick and should cover the whole length and width of the wall.

The mortar bed should be free from stones that could penetrate the flexible D.P.C. causing rising damp through the rest of the internal or external leaf.

Placing the D.P.C. roll at one end of a wall, gently unrolled and pressed into the mortar using the back of the Brick Trowel so that the D.P.C. adheres to the mortar bed.

Ensure that the D.P.C. does not go into the cavity space causing obstruction and D.P.C. external edges are visible and not bridged by the mortar when completing the pointing.

The bed mortar which is underneath the flexible D.P.C. should have a flush finish with the flexible D.P.C. extending from the face of the wall.

For additional information on this topic click on the links below:

Now you have cut your half-block placing safely to one side, move your corner blocks up to the next gauge mark on your end profiles.

Remember to place your wall ties correctly into the mortar and in the right position.

Start the second course of blocks with your half-block then lay 4 blocks with another cut half-block on the end of your course work, this will create stretcher bond in your block work

To complete this part of the assessment you need to repeat the first course up to 3 courses of blocks.

Double-check your block work before you set out your cavity wall, see the assessment criteria below.

This practical task is achieved by the following tolerances in the Grading Criteria.

The next stage in Constructing your cavity wall to clear away debris where the bricks are to be laid.

Remembering to use your P.P.E., normally assessment areas in a training centre are very dusty you will need to wet the surface area down with water before using your sweeping brush.

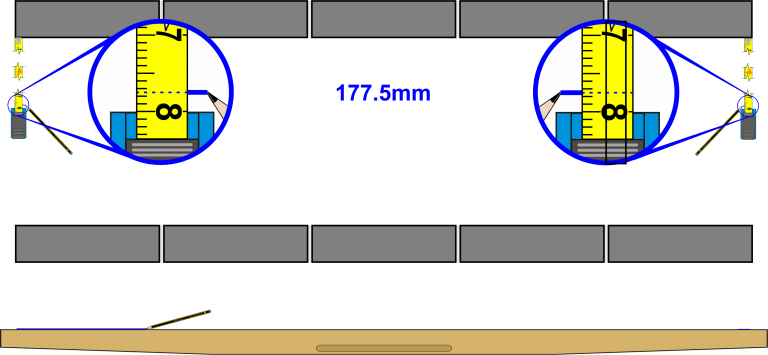

Mark out on each end of the wall 177.5mm this is will give you a Cavity Width of 75mm, then with the aid of a straightedge joiner the two lines together.

If you haven’t got a long enough straightedge, unwind a length of string line sufficient to span the length of the block wall, then wrap the string line around brick 2 to 3 times then run a taut string to the length of the wall place on the two end marks.

Using your split-level straight edge place onto the end and do an additional mark to the length of your spirit level, repeat this on the opposite end.

Remove the string line and join up or marks on your assessment area making sure that is one continuous straight line.

With the aid of a builder square place against the face of the blockwork and in line with the corner of the block then draw a continuous line the length of your building square and repeat and duplicate for the opposite end.

For additional information on this topic click on the links below:

Before setting up your profiles double-check your setting out make sure the length of the wall is 2240mm.

You need to check the profiles for any damage and they have sufficient upstand to carry out your assessment to the required courses of bricks.

Each end of your half brick wall requires a profile with the upstand of the profile placed on the marks previously made and in line with your face line.

Before you secure your end profiles with blocks you need to check for plum the face edge and stop end of the wall which is indicated in the image.

When setting out a building is good practice to place a course of bricks to gauge along the length of the wall in Dry Bond which is laying bricks without mortar on the bed and perp joints to the co-ordinating size of 225mm which is the working size of a brick with perp joint.

Generally, architects will design Buildings with the aid of a brick dimension table to minimise cuts during construction.

For ease of mixing the area should be flat, hard, e.g. Concrete, mixing board, and free from dust and other debris.

It is important that stones are not mixed in with mortar as these can affect the true laying of bricks and blocks.

Mortar will stain the surface over which they have been mixed even when the area is washed down after the mixes are used.

An area should be chosen where stains do not matter.

If possible, the area should also be close to where the work is taking place and/or near the stored materials.

The area should also be large enough to enable you to use all the tools and equipment Safely.

For additional information on this topic click on the links below:

Placed each corner block onto the end profiles making sure that the line is taut, adjust each corner block so that the line is the same height as your gauge rod markings.

Standing in your working space pickup a trowel of mortar and with the trowel just off the ground, swing your arm back towards yourself, turning your wrist, allowing the mortar to slide off the trowel along the string line this is known as the bed.

To complete this process using the point of the trowel make a v shape indent which is known as a furrow to the length of your mortar bed.

The first brick should be laid to line and the face of the brick should be set back slightly from the string line, otherwise you will foul the line which will cause a bowl in the face of your wall and be out of plumb.

The next brick should be ‘buttered up’ with mortar spread onto each end before being placed to abut the first brick.

The trowel should be used to cut away excess mortar that is squeezed out from underneath or in between the bricks.

Before starting in the next course of bricks double-check that your course work is level.

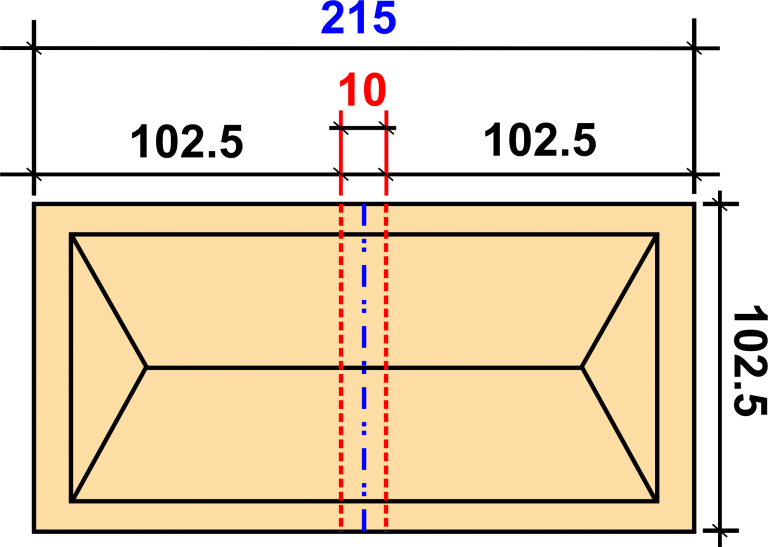

Stretcher bond is created by overlapping Blocks halfway, this is achieved by incorporating cut half-bricks on each end of the wall, on alternate rows to keep the correct bond

The cut side of the brock should be laid in line with the string line.

To maintain satisfactory appearance and achieve maximum strength to the wall you will need a number of cut bricks.

Don’t forget when cutting brick to a particular shape, you must allow for half of a 10mm joint for example, if you were to cut the above full brick along the dash/dot line, each half brick would be 5mm too big.

The correct place to cut the brick should be along the dotted lines.

Each half brick would then measure 102.5mm.

(102.5mm + 102.5mm = 205mm + 10mm joint = 215mm)

This method of marking your cut applies to all shapes of cut brick.

Failure to adopt this practice could lead you to lose your bond.

Now you have cut your half-brick placing safely to one side, move your corner blocks up to the next gauge mark on your end profiles.

Start the second course of bricks with your half-brick then lay seven stretcher bricks with another cut half-brick at the end of your course work.

For additional information on this topic click on the link below:

Before starting in the next course of Bricks you will need 100mm Damp Proof Course (D.P.C.).

Flexible D.P.C. is laid on to a fresh bed of mortar approximately 5mm thick and should cover the whole length and width of the wall.

The mortar bed should be free from stones that could penetrate the flexible D.P.C. causing rising damp through the rest of the internal or external leaf.

Placing the D.P.C. roll at one end of a wall, gently unrolled and pressed into the mortar using the back of the Brick Trowel so that the D.P.C. adheres to the mortar bed.

Ensure that the D.P.C. does not go into the cavity space causing obstruction and D.P.C. external edges are visible and not bridged by the mortar when completing the pointing.

The bed mortar which is underneath the flexible D.P.C. should have a flush finish with the flexible D.P.C. extending from the face of the wall.

Using a spirit level plumb the perp joints from the first course onto the Fourth Course using a pencil, this will help you to keep the perp joints plumb.

You need to check the first-course perp joints against the third-course perp joints to ensure they are plumb before starting your fourth course.

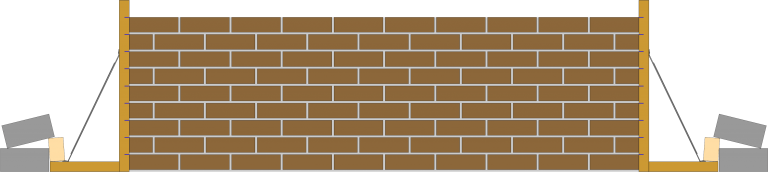

Continue laying courses of bricks until you reach the Ninth Course, by repeating previous steps.

Remember to remove surplus mortar that has been squeezed out from the joints.

Don’t forget to wear your Personal Protection Equipment when needed, you still being assessed as you pack away your tools and equipment.

Check that the face of the brickwork is flat with the straight edge and that the perpends are in line.

Fill any gaps in the joints with mortar, using a pointing trowel to press the mortar into the joint.

When the mortar has dried out sufficiently point up the brickwork with a jointing tool.

For additional information on this topic click on the link below:

Assessor Checking Work

Clean your working area off surplus Materials and Debris on completion of the job.

Clean all Tools & Equipment ready for reuse.

Double-Check your work and your area against the assessment criteria before calling over the assessor who will then ask you questions on this assessment.