Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

A bricklayer will come into contact with a wide range of materials whilst completing normal work procedures.

There are a large number of different types of bricks available and it is impossible to be familiar with them all.

The bricklayer should, however, be able to recognise the basic properties of a given brick such as weight, size, strength, colour, porosity etc. and know-how and where to use it to its best advantage.

A. Place of Origin.

e.g. Staffordshire slate blue, Yellow London Stock, Cambridgeshire Buffs

B. Colour

e.g. Reds, Creams, Multi-coloured.

C. Method of manufacture,

e.g. Pressed, Wire-Cut, Hand Made

D. Surface texture,

e.g. Rustic-Faced, Sand-Faced, Glazed

E. Use,

e.g. Common, Engineering, Facing Work

F. Size generally in relation to thickness only (gauge).

Yellow London Stock

Staffordshire Slate Blue

Cambridgeshire Buffs

These can be either Machine-Pressed or Wire-cut.

As the name suggests, they are manufactured from clay dug out of the ground and, depending on where the clay is excavated, can produce a variety of colours.

After excavation, the clay is weathered in the open to allow rain to wash out soluble salts.

If the clay is not weathered, these salts may be washed out of the bricks after laying – leaving a white stain on the face of the wall known as Efflorescence.

The clay is then taken to the grinding mills where a small amount of water is added and the clay fed into moulds if a machine-pressed brick is required or passed through a machine where a long length of rectangular clay is forced out onto a conveyor belt where it passes under a frame of wires that cuts the clay into brick thicknesses.

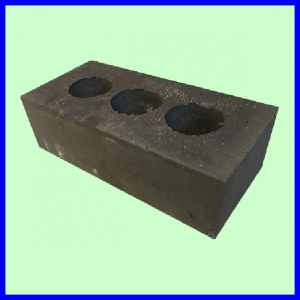

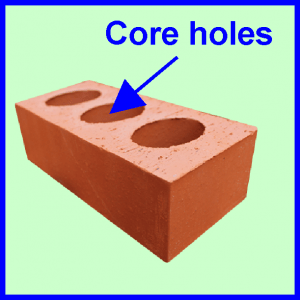

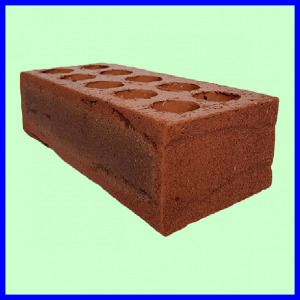

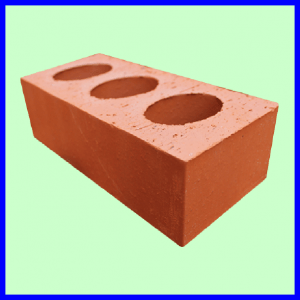

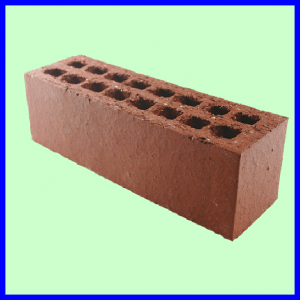

Bricks which have 3 to 4 holes in them are called Core Holes, during manufacturing, the holes are removed to reduce weight and costs.

Core holes make it easier to manufacture since the heat from the firing can penetrate into the centre of the brick.

When bedding these bricks onto a bed of mortar, the mortar squeezes through the Core Holes to form additional key and strength to the structure of the wall.

These are called wire-cuts.

The freshly made or green bricks are then dried and burnt in a kiln at a very high temperature.

After cooling they are ready for use.

These are manufactured in a different way from clay bricks.

Sand and lime are mixed together in the proportions of approximately 1 part lime to 8 parts sand (a ratio of 1:8).

A small amount of water is added and the damp mixture moulded into brick shapes.

The moulds are placed in a machine called an autoclave and steam is injected whilst the bricks are being subjected to very high pressure.

This pressure and steam injection are held for about eight hours.

A bricklayer usually classifies bricks according to their use.

Common Bricks:

These are general building bricks which can vary considerably in quality and which do not have a decorative face.

They are a cheaper type of brick and are normally used for unseen work.

Common Brick

Facing Brick

Facing Bricks:

The term facing brick usually describes a brick specifically used for its decorative qualities, many are produced from common brick class with a decorative finish applied to the header and stretcher faces.

Facings are normally more expensive than commons.

Sandlime Bricks:

Made from sand and lime or crushed flint and lime, moulded under heavy pressure and hardened by exposure to steam at pressure.

Sandlime Bricks

Engineering Bricks

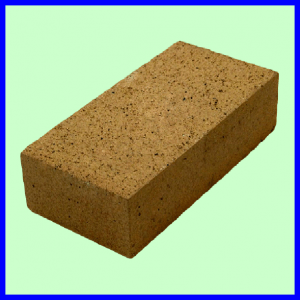

Engineering Bricks:

Are very hard dense bricks with a smooth texture.

They have a high load-bearing capacity and are used when strength, durability or moisture-resisting properties are required.

Engineering Bricks are ideal for retaining walls, damp-proof courses and for the construction of manholes.

Good quality Engineering Bricks are expensive and can weigh between 3.5 Kg and 4.5 Kg.

Modular Bricks:

Metric modular bricks can he produce as above and are available in various sizes:

300 x 100 x 100, 200 x 100 x 100 being two examples.

Metric-Modular Bricks

Fire-Brick

Refractories (Fire Bricks)

These bricks are made from specially selected clays which will withstand very high temperatures.

Refractory bricks usually contain 30-40% alumina and the primary raw material is usually chamotte with other materials.can weigh between 3.5 Kg and 4.5 Kg.

Depart from standard shape and size and as the name implies have to be purpose-made to meet some detail of the construction.

Bullnose and squint bricks are two of the more common types of special.

Special Bricks

Hand-Maked Bricks

Hand Moulded Bricks

This is the traditional method of making bricks.

Clay is hand thrown in moulds to produce a very characteristic finish.

The colour, shape, and texture of each brick will vary slightly due to the firing process.

Today, hand-thrown stocks are rare.

The method is labour intensive and therefore very expensive.

The appearance of hand-thrown stocks may be inconsistent over larger areas, and the arises (edges) tend to be rounded or slightly distorted.