Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

The learner will:

1. know how to prepare for Construction Operations Units.

Assessment Criteria

The learner can:

1.2 & 1.3 identify tools and equipment required for following Construction Operations Units

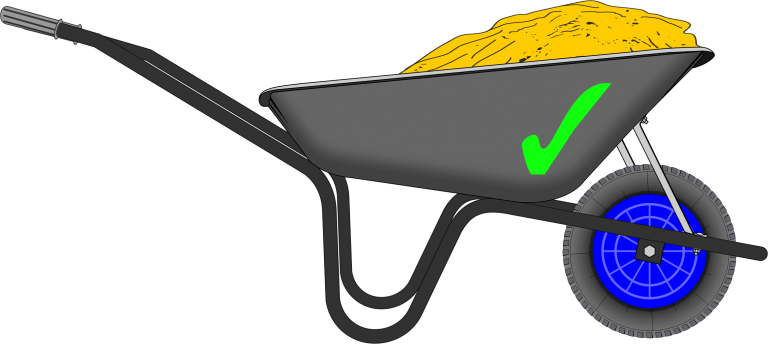

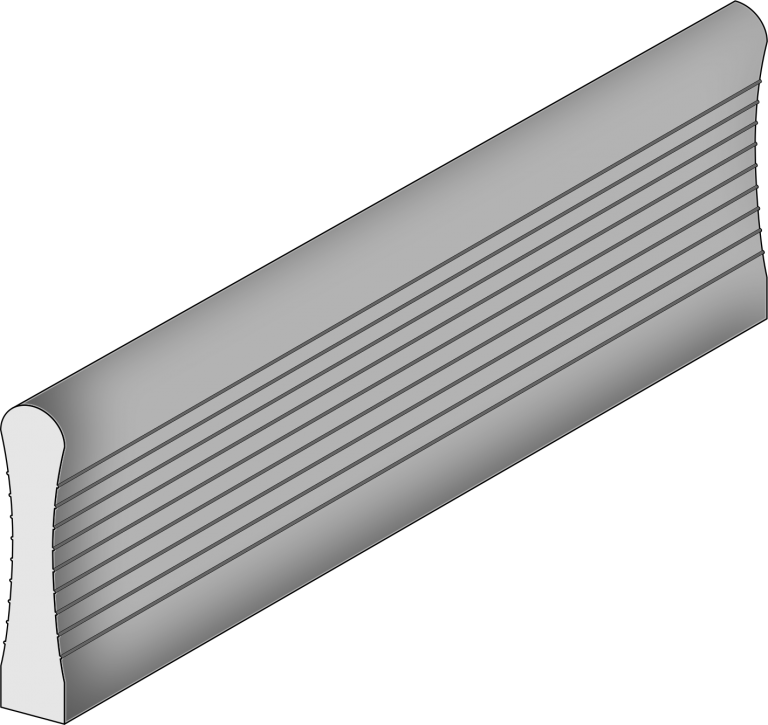

Feather Edge

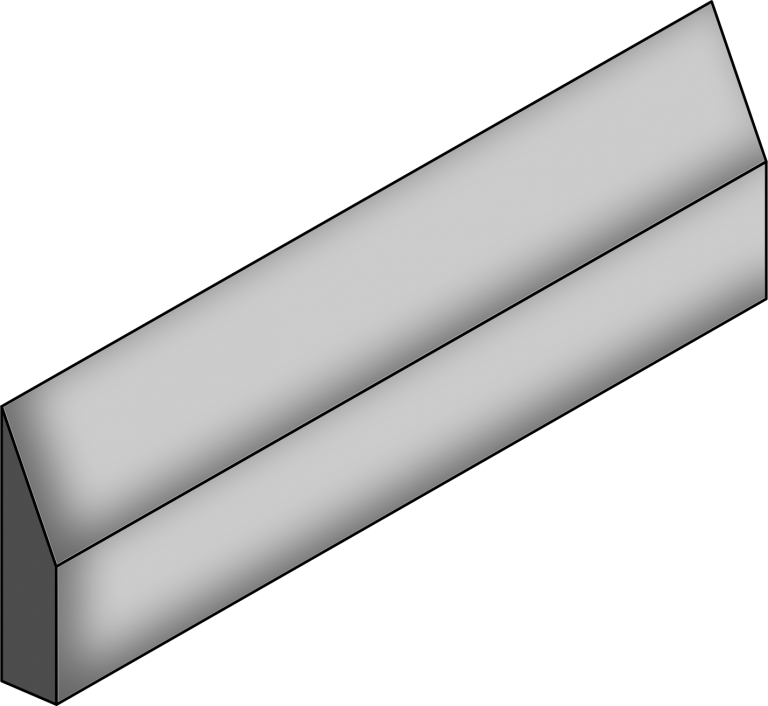

Screed Ruler, Straight Edge or Feather Edge are constructed out of Wood or Lightweight Materials like Aluminium with a blade of 150mm wide.

The Screed Ruler and Feather Edges come in various sizes up to 2500mm long.

The shorter lengths are manageable by one person, a second person may be required for longer lengths of rulers.

Straight Edge

Screed Ruler

Feather Edge

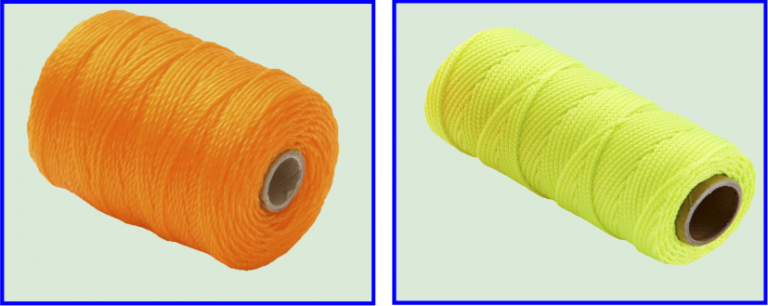

Ranging lines

Brick Lines

Cotton Lines

The Brick Line is also known as the Masonry Line or Ranging Line, the term “Ranging Line” is normally used for setting out the building and they need to be extra-long.

Brick lines speed up the job if you use them correctly, plus you are not using the spirit level so often, and give you a straight line for accuracy when laying bricks or blocks

Traditionally Brick Line was made from Cotton or good-quality Hemp ensuring that the Brick Line was not too thick.

The issue with Cotton and Hemp lines they have a tendency to get mildew, if they are allowed to get damp or wet this will affects the strength of the line.

Additional information on this subject can be found at the following links:

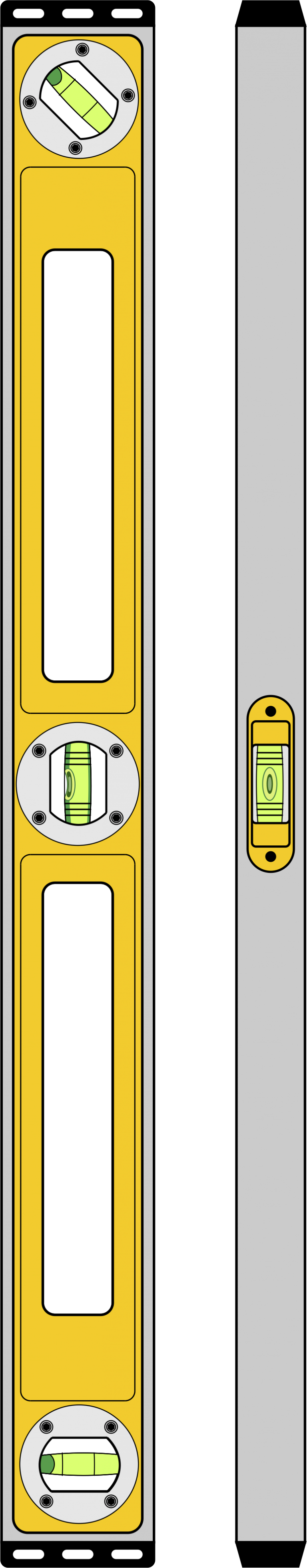

Spirit Level

A spirit level is one of the most expensive items within a bricklayers tool bag, it goes without saying spirit levels must be kept clean and do not allow mortar or concrete to dry on your level especially on the vials.

Misuse of a spirit level can lead to inaccurate horizontal (Level) and vertical (Plumb) on the surface planes.

Site agents or your supervisors will ask you to redo your work within the guided tolerances set out in the specifications document.

There are many different types of levels in the market, dependent on your trade and work you need to carry out will dictate to a certain degree the type of level which is most suitable for the job.

A bricklayer would generally use a level which is 900 mm in length or longer they also use a small torpedo level for the small intricate jobs like laying soldier course.

Construction workers needed spirit level which is extremely robust and able to keep their accuracy over a long time.

For interior work like tiling and carpentry may wish to spend a bit more money and get electronic spirit level or even a laser level, interior work is cleaner and you can maintain a clean level for a longer duration.

Spirit Levels

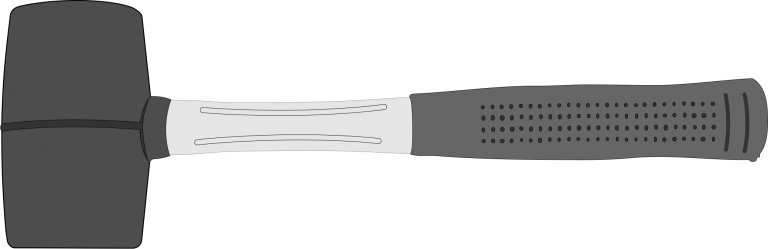

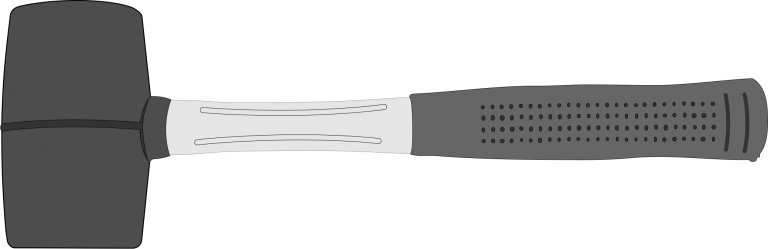

Mallet Rubber

Rubber Mallets as the name suggests has a moulded rubber head attached to the wooden or fibreglass shaft.

When adjustments and for levelling the pavers or wall units into the right position, this is an ideal tool for the task without leaving marks on the surface of surface area.

The weight of General-purpose Rubber Mallets from 16 to 24 ounces up to Block Paving Rubber Hammer with a head weight of 5-14lb

Mallet Rubber Block Paving

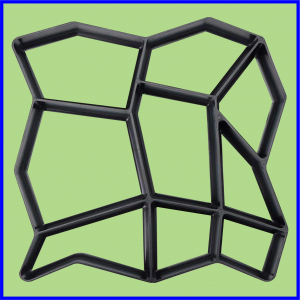

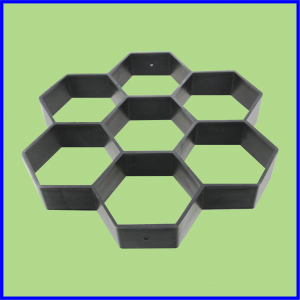

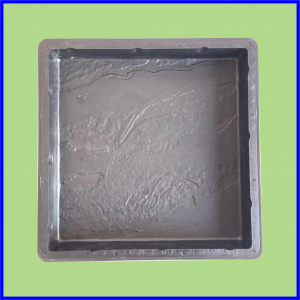

The cost of making your own slabs from moulds is approximately 50% cheaper obviously, the process is a lot slower and you need to make sure the consistency of the mix and quality of the workmanship must be maintained.

The moulds can be either bought by reputable dealers or you can make your one-off mould cast or duplicate the same mould.

When using any type of mould you need to apply a releasing agent this may require two coats to prevent the shape and pattern from being distorted when removing it after the concrete has cured.

Concrete increases in strength very quickly for 3-7 days. Concrete that is moist cured for 7 days is about 50% stronger than uncured concrete.

What is the mix for a strong concrete slab for moulding should be Cement, Sand and Coarse Gravel which provides 1:3:5 mixture.

You can use plasticisers which are added to concrete formulations to make them more workable and fluid for pouring, thus allowing the water contents to be reduced.

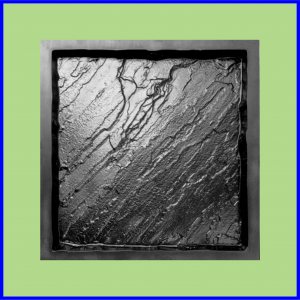

Yorkstone Slab Mould

Wavy Edge Riven Mould

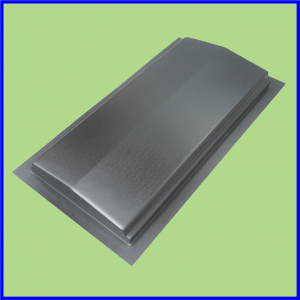

Wall Coping

Stepping Stone Mold

Quadrant Paving Slab Mould

Log Effect Stepping Stone

Log Edging

Hexagon Pavement Mold

Cavity Slate Finish Mould

Mallet Rubber

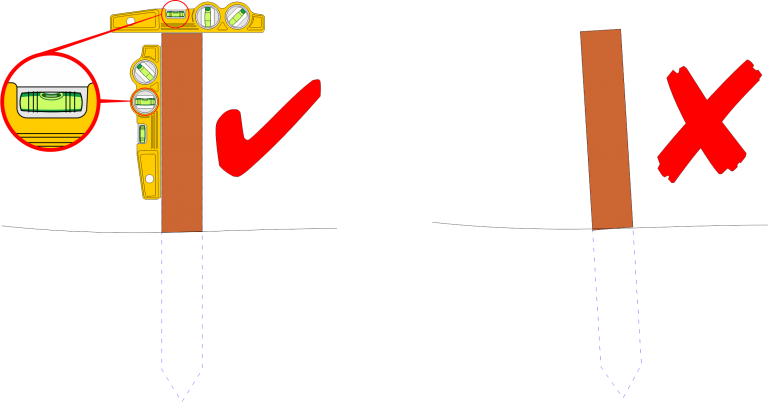

Wooden pegs also known as wooden stakes are used by surveyors to set out buildings.

Pegs are also used to set out general construction projects like footpath’s, fencing and are used in conjunction with wooden profile boards when setting out foundations.

Wooden Setting Out Pegs Size 50x50x600mm with tapered end making it easier to drive into the soil.

When setting out wooden pegs it is essential that they are plumb and level.

Setting Out Pegs

There are four basic types of saws that the carpenter and joiner will use on a day-to-day basis.

These are:

1. Rip saws.

2. Crosscut saws.

3. Tenon saws.

4. Dovetail saws.

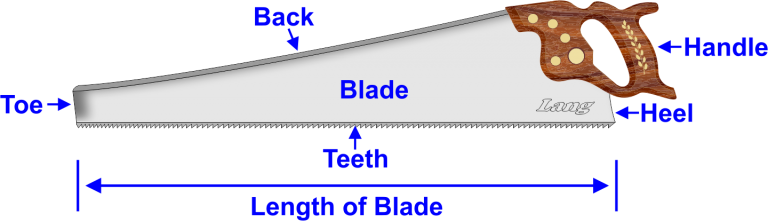

The diagram below shows the parts of a Hand Saw

Parts of a Hand Saw

Toe

The toe is the end of the saw away from the handle.

Back

The back is opposite from the cutting side of the blade.

It may have reinforcements to straighten the blade as you’re sawing something.

If there are no reinforcements, the back is meant to pass through the material that you saw.

Blade

This is made from good quality tool steel, hardened and spring tempered all over.

Handle

Usually made from hardwood or plastic.

The handle is fixed to the saw blade with brass screws and nuts.

Teeth

The teeth are cut along the edge of the blade.

They vary in size and shape according to the type of saw.

Heel

The widest part of the saw blade which touches the handle

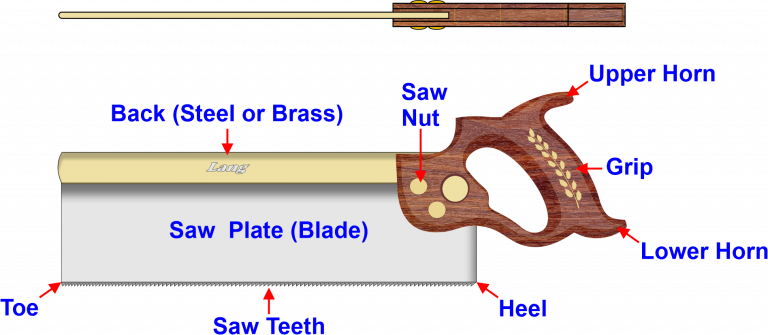

The diagram below shows the Parts of a Tenon Saw

Parts of a Tenon Saw

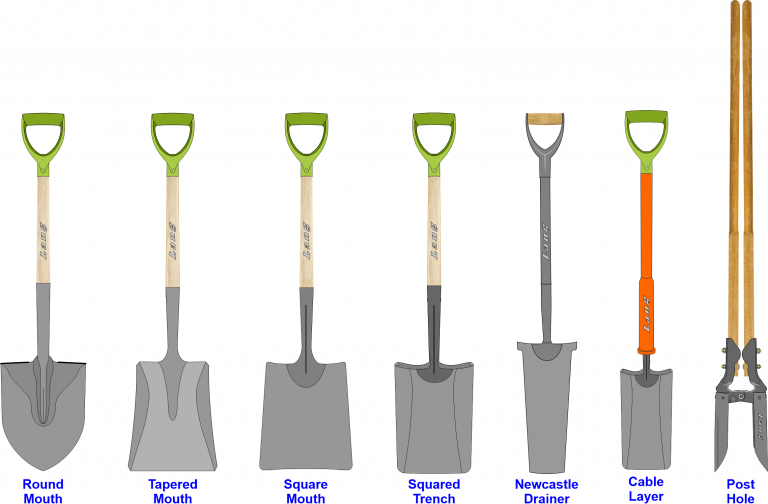

Most of the heavy digging on a construction site is done by excavator like trench for foundations, a sturdy shovel is needed to square off the sides of the trench.

Shovel blades are usually made of sheet steel for construction site work and the blades come in different shapes and sizes.

Selection of Construction Shovels

Additional information on this subject can be found at the following links:

Measuring tools are used to either transfer measurements from one component to another, or for checking known measurements.

Accuracy is all-important when either transferring or checking measurements.

At some stage in your training, you will have to take sizes from, or enter sizes onto a drawing.

Part of a Tape Measure

Flexible steel measuring tapes

These tapes are made of thin steel with calibrations in metric or a combination of imperial and metric.

They retract onto a small, enclosed spring-loaded drum and are pulled out and either pushed back or have an automatic return which can be stopped at any distance within the limit of the tapes length.

The length of these tapes can vary in overall length ranging from 2m to 8m.

Range of retractable steel measuring tapes

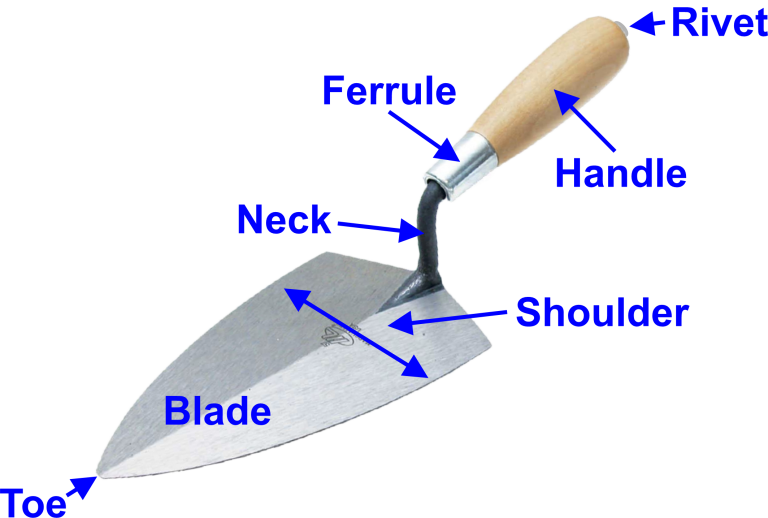

To build any wall we need a trowel to lay the mortar for the bricks or blocks, and for the face brickwork, a pointing trowel and a jointer to provide a finish to the joints.

Part of a Brick Trowel

These come in various shapes and sizes ranging between ten and fourteen inches.

One side of the trowel has a more rounded edge, this being for rough cutting, however, this use is not advised for the beginner.

The measurements are the actual blade size, the width of trowel also varies and beginners will find a narrower trowel easier to use.

The rounded side on the trowel makes it suitable for both left and right handed operators.

When the trowel is not in use for a period of time, clean it off dry and apply a light coat of oil to avoid rusting.

Brick Trowel

Brick Pointing Trowel

This is a small trowel used for filling in the joints of brickwork or blockwork.

The process of filling in the joints is called pointing.

This trowel is similar in shape to a bricklayer’s trowel but approximately 150mm long and it does not have a tempered edge for cutting bricks.

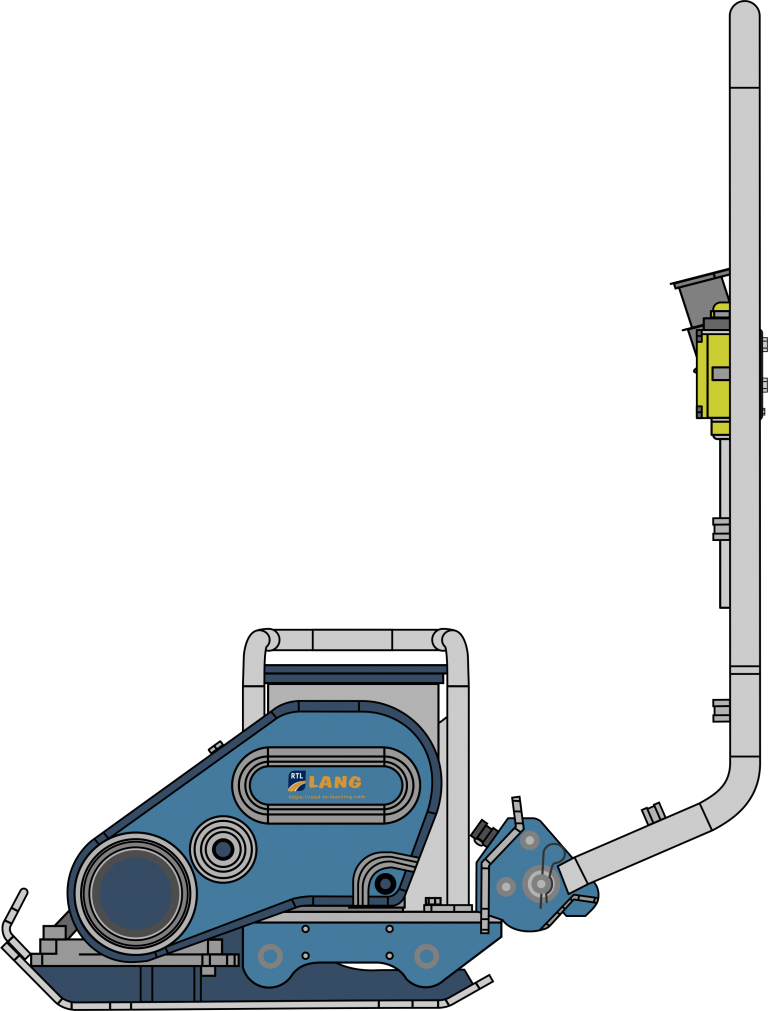

Vibrating Plates or Wacker Plates are ideal for compacting soil, sand and/or loose gravel into a solid compact base.

The solid compact base is ideal for new pathways or driveways ready to receive paving bricks, Concrete Slabs, or Concrete.

Vibrating Plate

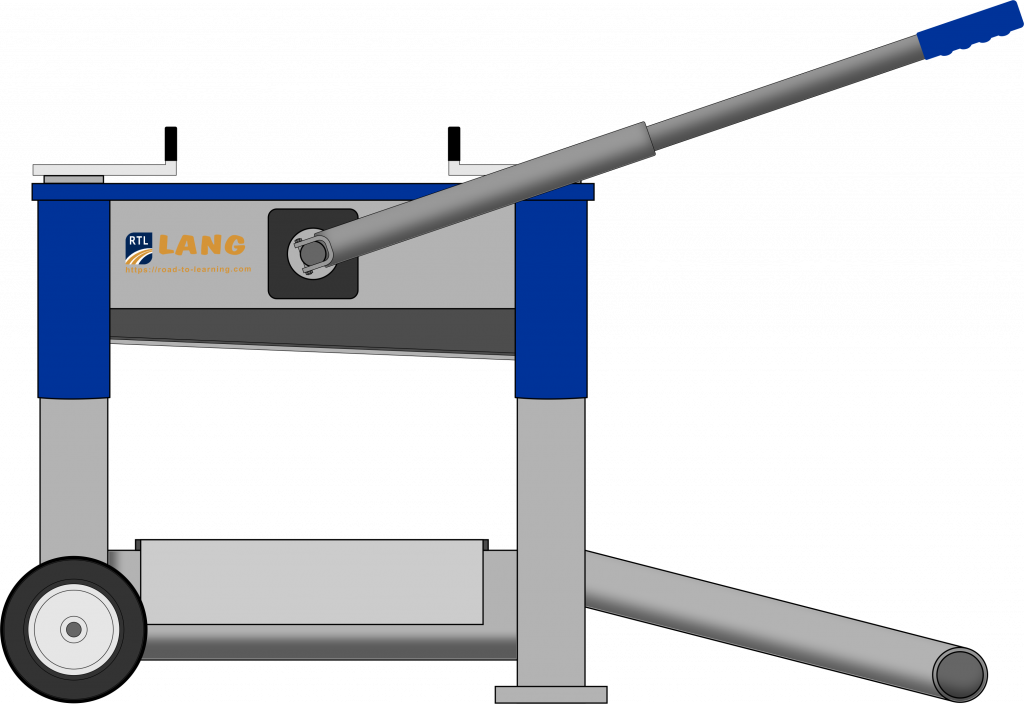

Hydraulic block splitters are a quick and easy way of cutting blocks, bricks and slabs without creating dust or using electricity which is the best choice full year of environment and running cost.

Using a splitter you can place the materials to be cut in approximately 3-5 seconds why a power saw often take a lot longer depending on the depth of the material, blade condition and the skill of the operator.

The splitter is place on a firm level ground then the blade adjusted to suit the materials, the materials are placed on the block surface shelf.

The operator stands on the stabilising brace to support the cutting process, the upper blade is moved by hydraulic telescopic lever moving the upper blade down onto the materials to be cut.

Block Splitter

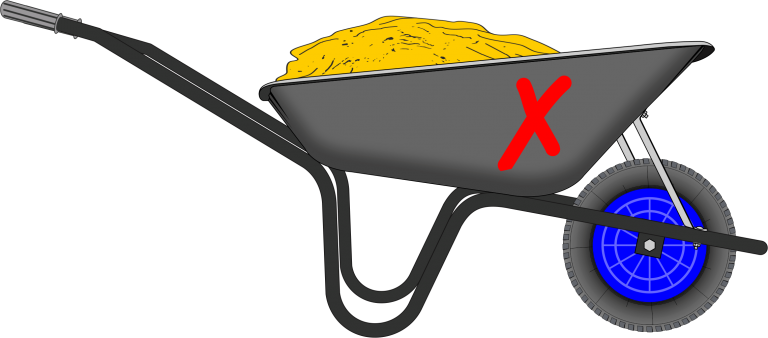

There is a wide selection of construction wheelbarrows available, ideal for transferring small amounts of materials such as sand, aggregates, or small building components like bricks.

Never overload a wheelbarrow and have most of the weight over the front wheel.