Line Pins

Traditional Line Pins

Tapered Line Pins

Dutch Pins

Dutch Pins

There is a wide variety of pins to choose from, as you can see from the above and that is only a small sample.

Dutch Pins used by bricklayers and plasterers to temporarily hold profiles and wooden battens in place.

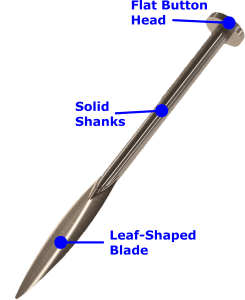

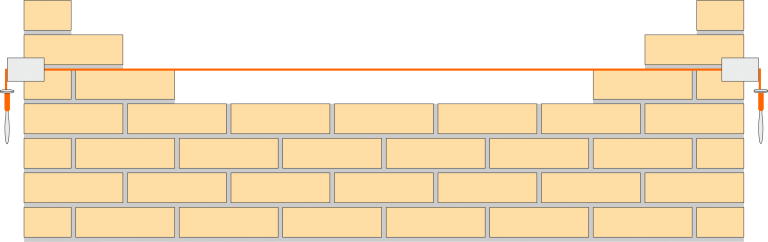

Line pins are short metal stanks with a leaf-shaped blade that can be inserted into a mortar joint to form an anchor point, the pins help to keep the line under tension between two points.

This ensures that the brick course-work are built straight and level as long as you haven’t got any knots or mortar on the line which will cause inaccurate brick course-work.

Flat button head ensures that the line doesn’t come off the end of day shank, also used to hit with the brick hammer if needed.

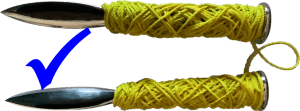

How to load brick line onto the pin correctly

When buying a new set of brick line pins ensure that they are good quality, they need to be able to take a lot of punishment from a brick hammer or lump hammers.

![]()

Line Pins Step 1

Now you got your new set of brick-lined pins, you need to protect the line by applying insulation tape around the shank this prevents lines been affected by rust which will affect the strength of the line and liable to break under tension.

![]()

Line Pins Step 2

Now you need a good strong brick line, a line which has interlocking braided pattern is the strongest line to have for more information go to Brick Lines.

You need to secure the line to the pin shank, then bring the line down to the top of the leaf-shaped blade which you are holding.

Line Pins Step 3

While holding the blade wrap the line around the shank two times, then moved the line to the underside of the flat button head.

Line Pins Step 4

Still holding the blade wrap the line around the shank and underneath of the flat button head, you repeat steps four and five until you have sufficient line on one pin.

Line Pins Step 5

During the process of winding the line around the pin shank, it is advisable to create a half hitch on the underside of the button head

Place a half hitch on the pins every 5m to prevent the line from unwinding should the pin be dropped while working on a scaffold.

Line Pins Step 6

Once you have sufficient line on the first pin repeat the process for the second pin, it is advisable to do step 6 before moving onto the next pin.

Line Pins Step 7

As you can see by moving the line up and down the shank, you have created pockets in between string which helps to dry out the line a lot quicker otherwise you will get what we call bag rot on the line which will seriously impair the strength of your line and it is more likely to break then you’d have to splice together.

To see how to splice a line go to Brick Lines

Line Pins Step 8

This method of loading the line onto the pin shank is incorrect, it will take a lot longer for the line to dry and you are more likely to get bag rot on the line.

Line Pins Step 9

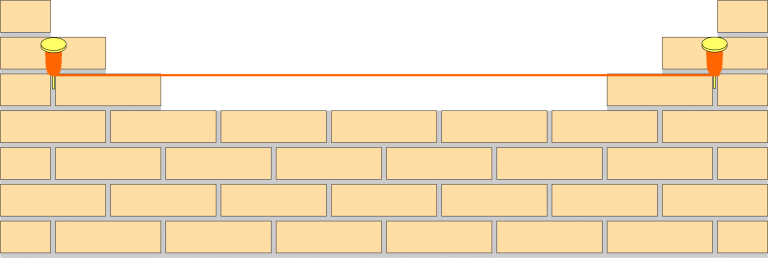

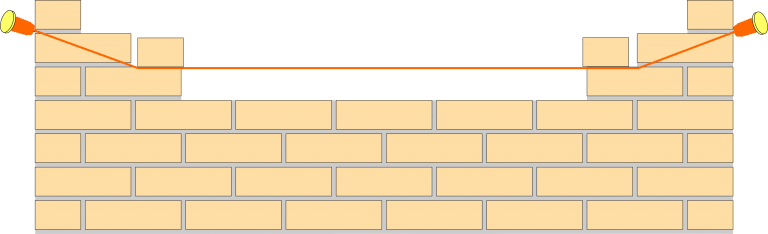

Positioning the Pins

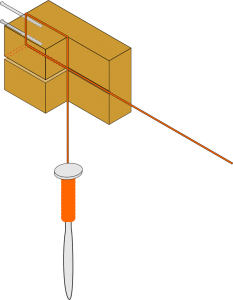

Wrap the line around on the top part of the blade, insert the blade into the perp joint nearest the Quoin or Rack Back.

Position the second pin by unravelling the line so it reaches the opposite Quoin or Racks Back, once again wraps the line around the top part of the blade and insert it into the perp joint nearest the Quoin or Rack Backs.

The line needs to be taught enough so that there is no sagging in the middle of the wall if you still have an issue with sagging then use a tingle plate.

The tingle brick should be as near the centre of the wall as possible and must be sighted through from Quoin to Quoin (or Rack Backs) at approximately every six courses as work proceeds.

You need to make sure that the line is on the correct course on both ends and make sure the top arris of the brick is level with the line along the full length of the brick.

If you find that when you are tensioning the line you disrupt your brickwork? use Option B

Option A

Option B

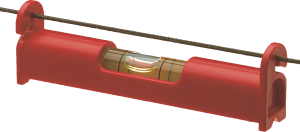

Line levels

Line levels are light enough to sit on the line without creating the line to sag when checking the line for level.

Attach the line level to the middle of the line using the small hooks on the line level, if you find that the line is not level this may be due to the sagging of the line or inaccuracies gauging when building your quoin from the datum point

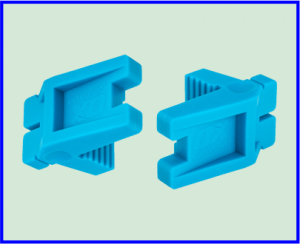

The Corner Block

Corner blocks are used in preference to pins as they eliminate making good pinholes and they are less likely to disturb the corner.

The function of a corner block is to hold the line taut and at the correct height so that the bricks or blocks can be laid to the level.

Corner Block are used in pairs and they come in different materials and different shapes.

Rubber Corner Blocks

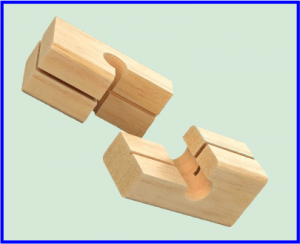

Wooden Corner Blocks

Aluminum Corner Blocks

Line Clamps

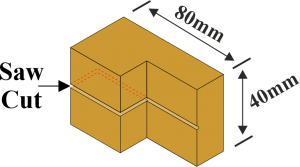

Traditionally bricklayers corner blocks were made out of wood, the blocks have sawn slots in them for locking the line.

The line is pulled through the saw cut and taken once under the line, and through the saw cut again, If you have a set of nails on the end of the corner blocks, using the line do a figure 8 around the pens to securely line from slipping

Hitch the line round the pin to prevent it from hanging down too far.

Place the corner block on the quoin or Rack Back, lengthways in the direction of the brick course infill.

Keep the line taut to prevent the block from falling and move to the opposite quoin or Racking Back.

Pull the line through the block as before.

The amount of tension necessary to keep the line taut and with no visible sag when sighted will depend on the length of the wall between corners.

Remember with any excess line make sure that you wrap it around the pin shaft finishing off with half hitch, this will avoid any trip hazards.

Using the line-level check for accuracy, before starting to lay any bricks or blocks.

Once corner blocks are set up correctly, they can be moved up and down the coin a lot easier and faster than pins with the additional benefit of not leaving pin-holes.