Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

3. understand how to erect cavity walling to required specification.

The learner can:

Personal Protective Equipment

You must use approved Personal Protective Equipment whenever you use Hand tools or Machinery when cutting bricks.

Personal Protective Equipment cannot eliminate the risk of injury but it will reduce the degree of injury if an accident does happen.

The Health & Safety at

Work Act 1974 (HASAWA)

Minimum amount with P.P.E. on Construction Site before you start any activity.

Hand Protection

Protective Footwear

Head Protection

High Visibility

It should be noted that because of the dangers of flying debris, Health & Safety Regulations require the wearing of eye protectors when cutting bricks with a hammer and bolster.

Additional P.P.E. when cutting bricks or blocks on site.

Manufacturer’s instructions on P.P.E. should be followed in conjunction with your Company Health and Safety Policy plus, RAM`s (Risk assessment And Method statements)

Earplugs

Ear Protection

Wear Dust Mask

Wear Goggles

Wear Apron

Wear Face Shield

Cutting bricks can cause brick fragments and dust to enter the eyes and other parts of the body.

The cutting action generates high levels of dust, which often contains high crystalline silica content.

Breathing in this dust can lead to the development of respiratory ill health, in particular scarring of the lung tissue (silicosis) which can result in serious breathing difficulties, depending on the extent of exposure.

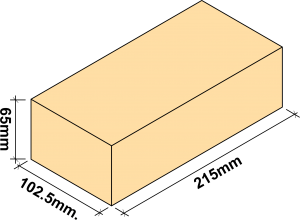

The brick dimensions stated by the manufacturer are known as the work size.

The most widely used work size for UK clay bricks is 215 x 102.5 x 65mm, any new work the bricklayers should check the dimensions of the brick he also sees our going to be using.

If you have a concern about the dimensions of a brick supplied then you need to do a simple tolerance test.

Brick Dimensions

The successful design and construction of brickwork require the designer to consider the material when setting out, in both plan and elevation.

By setting out to multiples of brick dimensions, cut bricks and awkward bond patterns can be avoided.

This will improve the aesthetic of the finished building.

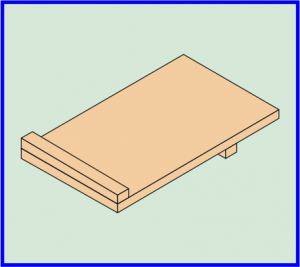

The bonding of bricks entails the use of bricks cut across their width (bats) and along their length (closers).

Unfortunately, there will be times when you need to use broken bond in your brick wall because of the length of the wall or window or door openings are not to brick sizes.

To maintain the satisfactory appearance and achieve maximum strength to the wall you will need a number of cut bricks.

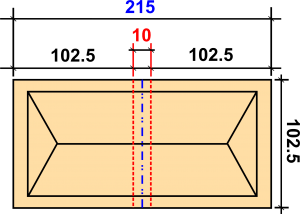

Don’t forget when cutting brick to a particular shape, you must allow for half of a 10mm joint, for example, if you were to cut the above full brick along the dash/dot line, each half brick would be 5mm too big.

The correct place to cut the brick should be along the dotted lines.

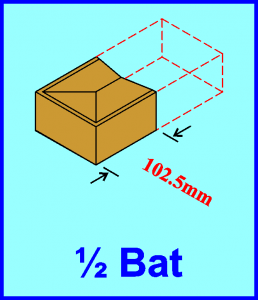

Each half brick would then measure 102.5mm.

(102.5mm + 102.5mm = 205mm + 10mm joint = 215mm)

This method of marking your cut applies to all shapes of cut brick.

Failure to adopt this practice could lead you to lose your bond.

Half Brick Cut Dimensions

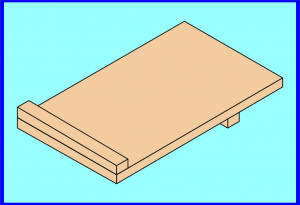

If we have a large number of cuts to produce, a simple brick cutting gauge can aid fast, accurate marking when cutting bricks, such as building a broken bond in facework.

Whether we use a brick cutting gauge or a tape measure and pencil to mark the brick, always aim for accuracy.

Accurate clean cutting maintains neat and plumb perpends.

This will make producing a quality piece of brickwork a much easier task.

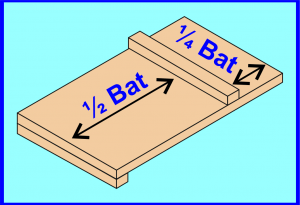

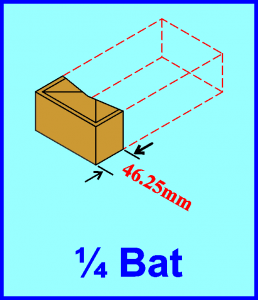

The different parts of the brick cutting gauge allow you to easily and accurately mark the measurements for a ¼ Bat, ½ Bat and ¾ Bat

Brick Hammer

Try Square

Tape Measure

Scutch Hammer

Scotch Chisel

Lump Hammer

Bolster Chisel

Sliding Bevel

Brick Trowel

Brick Cutting Gauge

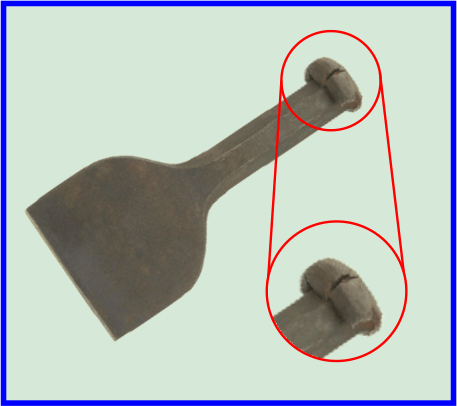

The most common tools used for cutting bricks are a bolster chisel and a lump hammer.

The bolster chisel is made of tempered steel and has a cutting blade about 100mm wide.

One of the best ways of assessing the standard of bricklayers is to examine the accuracy and neatness of their cutting of bricks.

High standards depend on skill, care and attention and the use of the correct tools and established techniques.

Remember

All hand tools and equipment should be visually checked for faults before use

Don’t use a chisel with a mushroom head as particles can fly off and enter the eye or other parts of the body, always use a hand protection grip and gloves, ensure the mushroomed head is ground off safely by using eye protection and grinding in a safe area.

The use of masonry bench saws is effective and advisable when large numbers or particular types of bricks have to be cut.

Experience suggests that while 3-hole perforated bricks can be cut satisfactorily by hand it is very difficult to cut multi-hole perforated bricks accurately and consistently without creating a lot of waste.

Similarly, the cutting of very high strength, low water absorbency solid bricks will almost certainly require a bench saw.

Masonry bench saws are particularly useful for cutting bricks at an angle which can be very difficult to do by hand.

Masonry Bench Saws Wet Cut

Masonry Bench Saws Dry Cut

Mitre Saw

Angle Grinder

Never use any electrical equipment without being trained (Competent) and always follow manufactures instructions or companies RAM`s (Risk Assessments and Method Statements)

Make sure you are wearing the correct P.P.E. (Personal Protection Equipment)

Always use 110v extension lead and transformer, ensure these are in good condition and heavy enough to carry current needed for electrical equipment you’re going to use

Your employer should ensure that a maintenance record is available and kept up-to-date, power tools should be pat tested.

Do not use the machine unless you are able to call for help in the event of an accident.

Always have a first aid kit nearby.

Check damaged parts at the beginning of every session with the power source turned off and unplugged.

The main checks for masonry bench saws are:

Ensure you check and report any defects and that all equipment is inspected before and after use.

Do not modify equipment, only use the manufacturers recommended accessories.

All blade guards are working correctly.

Blade’s need to be checked that there are on the spindle correctly and don’t wobble, also the right blade for the materials that you wish to cut.

The sliding table or cutting area should be clear of any tools and objects at all times.

Read the manufactures manual on how to stop the equipment safely in an emergency.

Handles should be kept dry and free from grease and oil.

The working area should be kept clean of clutter, dispose of offcuts into a container otherwise may cause a trip hazard. (See Good Housekeeping)

Bench saw should be set up on the firm-level ground with plenty of ventilation and light.

Don’t use power tools in damp or wet locations, or expose them to rain.

The sliding table should be checked to make sure it runs smoothly on the rails.

Water supply should be constant to reduce sparks and dust when inefficient water is reaching the blade.

The only exception is the new types of bench saws that do not require water like the IQTS244 Dry Cut Tile Saw 230 & 110 volts from IQ Power Tools.

Bench saw when not in use should be disconnected from the electric supply source, and don’t leave tool until the blade comes to a complete stop.

Always remove your hearing protection as soon as the motor stops to enable you to hear warning shouts.

Loose clothing should not be worn like neckties, rings, bracelets, or other jewellery which may get caught in moving parts.

Keep proper footing and balance at all times and don’t overreach.

Regardless of the size of the bricks that you use, there are a few types of cuts that are commonly used in bricklaying.

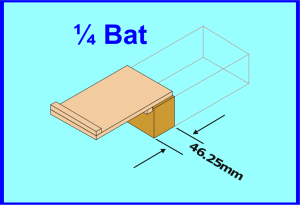

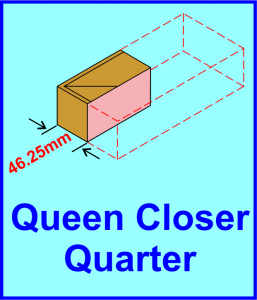

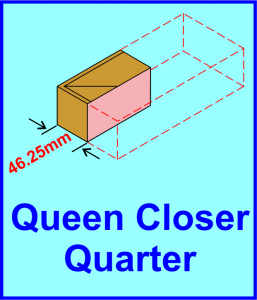

¼ Bat is a brick is cut across the width with a brick face size of 46.25mm, resulting in the same face size as a queen closure and Queen Closer Quarter.

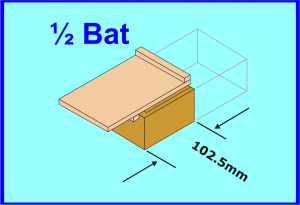

½ Bat is a brick is cut across the width with a brick face size of 102.5mm, ½ Bat with a perp joint (10mm) is the same size as a standard brick being 215mm

In the stretcher bond, the most frequently used cut is a half-bat.

Cut Bats in a broken bond should be placed as near to the centre of the wall as possible.

When a ½ Bat is built into a course of brickwork, the course above and below it will contain two ¾ Bat cuts to maintain the bond.

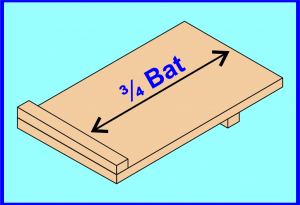

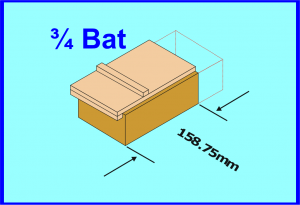

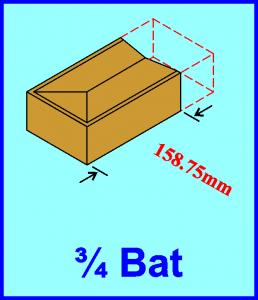

¾ Bat is a brick is cut across the width with a brick face size of 158.75mm which measuring ¾ quarters of the length of an uncut brick (215mm), this is commonly used at

In a broken bond ¾ Bat should be placed as near to the centre of the wall as possible.

When a ¾ Bat is built into a course of brickwork, the course above and below it will contain two ½ Bat cuts to maintain the bond.

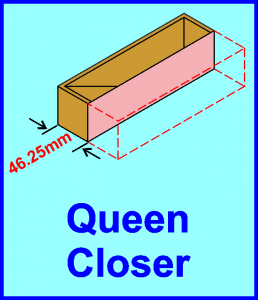

Queen Closer

A brick closer is defined by a cutting a brick lengthwise into two equal halves, the full length of the brick remains intact, this is called the Queen Closure.

The face of the Queen Closure which is visible measures 46.25mm, it is often placed next to Quoin Heather or Tie-Brick in one brick on alternative courses.

Queen closer maintains 1/4 bond ensuring there are no straight perp or cross joints between each course in a one brick wall like Flemish bond and English bond.

Queen Closer Quarter

If a queen closer is broken into two equal pieces then it is known as queen closer quarter.

Such a closer is thus a brick piece which is one-quarter of the brick size.

Queen Closer Quarter

If a queen closer is broken into two equal pieces then it is known as queen closer quarter.

Such a closer is thus a brick piece which is one-quarter of the brick size.

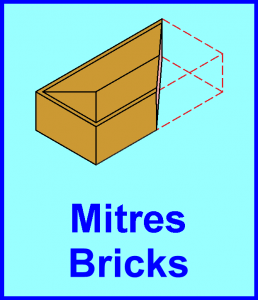

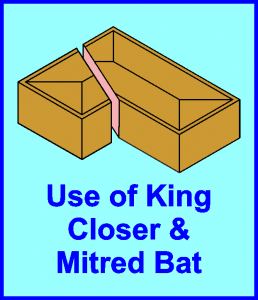

This method is more complicated and involves cutting bricks to form mitres so that the half bond can be maintained

Mitred Bat

It is a portion of a brick whose one end is cut splayed or mitred for full width. The angle of splay may vary from 45° to 60°.

Thus one longer face of the mitred closer is of the full length of the brick while the other longer face is smaller in length.

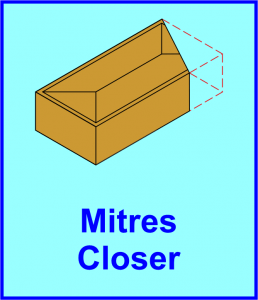

Mitred Closer

The angle of splay may vary from 45° to 60°.

Thus one longer face of the mitred closer is of the full length of the brick while the other longer face is smaller in length

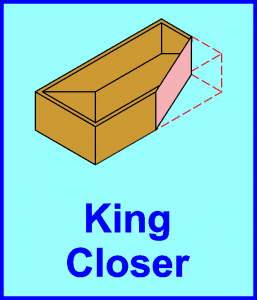

King Closer

One corner of a brick is so cut as to remove half the header and half the stretcher.

It is used when two walls meet at an angle.

Brick that is obtained by cutting from the centre of one header to the centre of the stretcher on the other side. They are used to finish corners.

If a brick is cut in such a way that the width of one end becomes half that of full brick, while the width at the other end is equal to the full width, then it is called as king closer.

It is obtained by cutting out a triangular portion of the brick between the centre of one end (width side) and the centre of the other end (lay aside).

Thus it has a half header and half stretcher face.

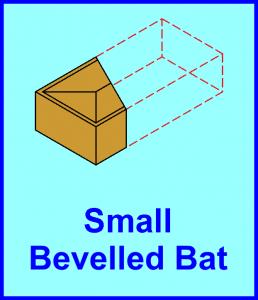

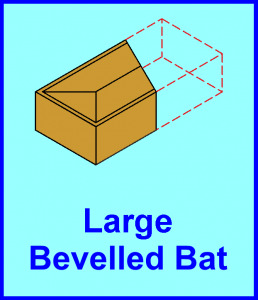

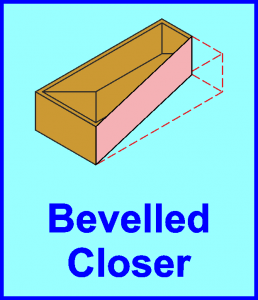

Bevelled Closer

Similar to king closer but wit the difference that the whole length of the brick is bevelled

It is a form of king closer in which the whole length of the brick (i.e. stretcher face) is chamfered or bevelled in such a way that half-width is maintained at one end and full width is maintained at the other end.

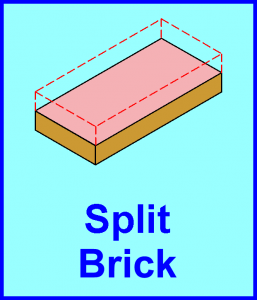

Split Bricks

Normally split bricks to use at the base of the wall to enable you to set your brick courses to the required level, normally DPC level on a construction site

The aim is to produce clean sharp edges especially on the face side of the cut brick.

This will ensure a good appearance in the finished wall.

When cutting bricks, a small mound or layer of sand should be used as a firm cutting pad.

The standard supports the brick evenly and minimises the risk of shattering or breaking in the wrong place

Alternatives to sand could be pads made from D.P.C. offcuts or layered sacking.

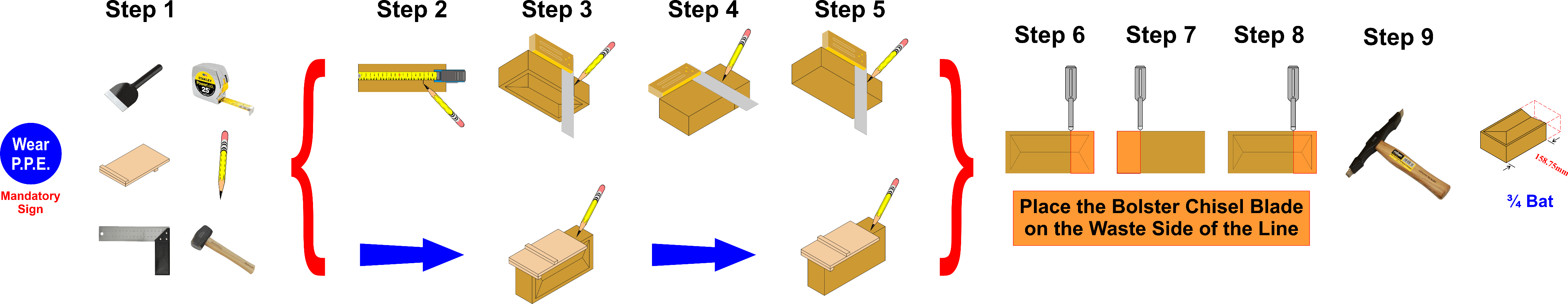

A sequence of operations for the cutting of bricks using a hammer and bolster is shown below.

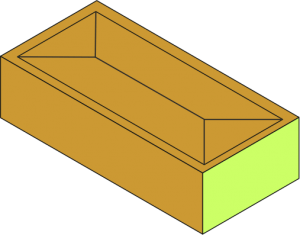

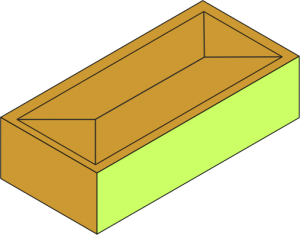

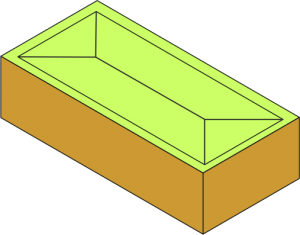

Header Face

Stretcher Face

Frog or Indent

Bed Face

The sequence of cutting a three-quarter bat brick,

the sequence will apply to any type of cut for masonry components like bricks and blocks.

Step 1

Before cutting any Masonry Components make sure that you wear the appropriate approve P.P.E., and choose an area which is safe for yourself and others when cutting any Masonry Components activity.

Before using any tools or equipment make sure that you have checked for any damage before using them if damaged reported to your supervisor and label it saying do not use.

Step 2

Find a firm level ground then using a tape measure mark out 158.75mm on the Stretcher face side is uppermost

Step 3

Place the Try Square Blade onto the face so it lines up with your mark, ensuring that the square sits squarely on the brick strike a line across the Stretcher face of the brick.

Step 4

Turner brick over so you’ve got the bed face side is uppermost, with the aid of the Try Square striker line across the brick ensuring that the Try Square Blade is lined up with the Stretcher face line that you created earlier.

Using brick cutting gauge eliminates this step in the cutting process.

Step 5

Turner brick so the Stretcher face side is facing the ground, and repeat as before.

Step 6

Ensuring that you place the brick on a bed of sand or layers of DPC material with the face side of the brick is uppermost.

Placing the bolster chisel blade on the waste side of the line, hitting the bolster with a lump hammer with the strength of the blow sufficient to mark or create a hairline crack without breaking the brick, the strength of the blow comes with practice.

Bricks which have coring holes like engineering bricks which have got high strength, they are best cut by mechanical means, otherwise, you might find that you have created a pile of broken bricks.

Step 7

The Stretcher face needs to be face down so you can repeat the process above.

Step 8

Repeat step 6 ensuring that the blade of the posters placed squarely onto the mark you made earlier, strike the bolster with the lump hammer and it should break along the lines made previously.

If cutting is not complete by the third cut the sequence of cutting blows should be repeated until the brick is cut.

Step 9

Any rough edges should be trimmed using a Scutch or Comb Hammer.

As you can see the difference between marking with a tape measure and using a brick cutting gauge, the brick cutting gauge requires fewer steps and it is more accurate.

With practice, you can hold the brick cutting gauge and bolster in position, then striking the bolster with a lump hammer with the required strength of the blow.

Angle Grinder

125mm Diamond Cutting Disc

With an angle grinder, you follow all the steps above except for steps 6 to 8, hold the brick in your hand firmly and away from the cut mark.

Switch on your angle grinder with a masonry blade, gently cut along the mark on the stretcher face side to a depth of approximately 5mm scoreline.

By doing the score line you ensure that you have a nice straight cut on the face side of the brick, with the angle grinder repeat the process again to the full depth of the blade remembering not to force the blade to let the blade do the work.

Repeat the process on the remaining sides of the brick, to complete the process hit the brick using a brick hammer on the waste side the brick should break into 2 pieces cleanly along the score lines

Remove any rough edges and should be trimmed using a Scutch or Comb Hammer.

Masonry Bench Saws Wet Cut

Masonry Bench Saws Dry Cut

Mitre Saw

Diamond Blade

If you are doing a lot of cuts for Broken Bonds or Queen closures then the above saws would increase your productivity and your accuracy, remembering about the safety rules for masonry bench saws previously mentioned.

You can set up the masonry saw with a fence and clamp to hold the bricks in position while cutting, the first cut should be on brick face letting the blade do the work without applying too much force otherwise you are more likely to have an accident or damage the masonry blade.

There are many types of Masonry Bench Saws or Mitre Saws that can be used for cutting bricks, some will cut dry and others will need a water-cooled reservoir to keep the sparks down and the heat on the blade.

Water-cooled bench saw you need to keep an eye on the water level so that the blade is continually passing through the water, it is useful to have additional P.P.E. like an apron to keep yourself dry.

Remembering to change the water if you’re using different types of bricks otherwise, you could stain the bricks if you allow them to dry.

Operatives using the water-cooled system must allow the bricks to dry before giving in to the bricklayer, ideally do all your cuts the day before bricklayer requires them.

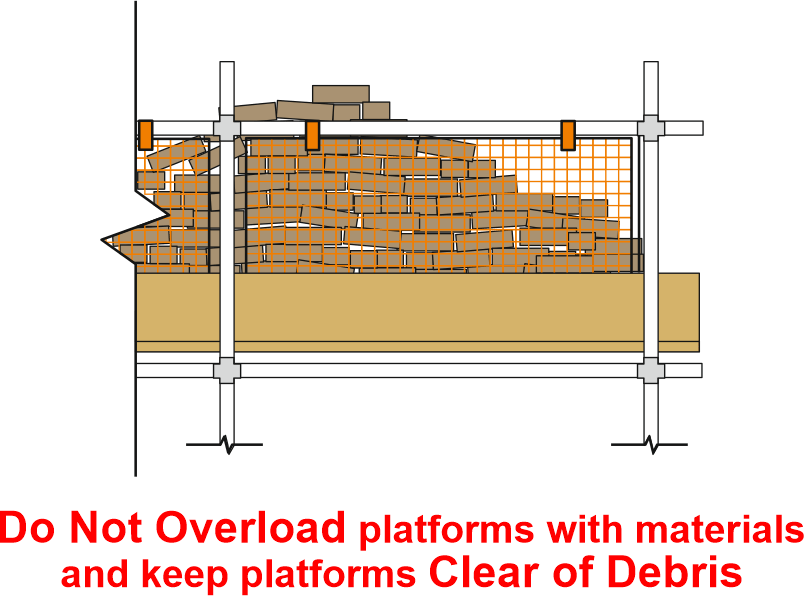

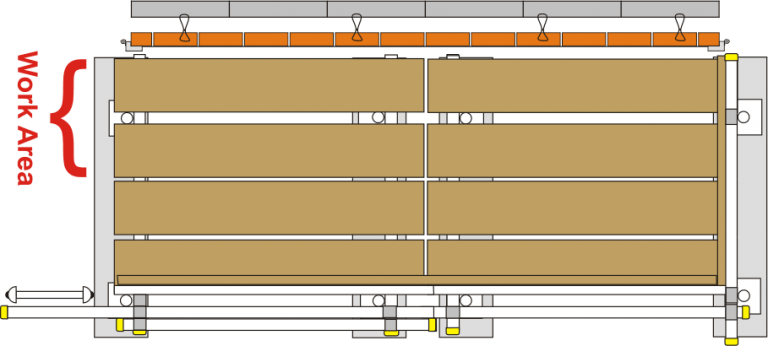

A scaffold is a temporary structure erected to support access or working platforms. Scaffolds are commonly used in construction work so workers have a safe, stable work platform when work cannot be done at ground level or on a finished floor.

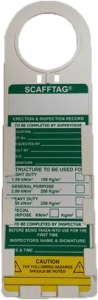

Check Scaffolding inspection tag to make sure that the scaffolding has been checked in the last seven days, make sure that somebody has an altered or removed any scaffold boards and the platform is fully boarded out.

Scaffolding Inspection Tag

When bricks have to be cut when on scaffolding, adequate space should be allowed, possibly by the removal of the spot board or a stack of bricks.

It is vital that the Working Area is kept clear of brickbats, rubble and tools, this area is the two scaffold boards closest to the face of the wall.