Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

The specification contains important details including, among other things, what materials should be used, the standards of workmanship required and the methods of work that should be employed.

The finished job will only meet the design requirements if the bricklayer continually checks that his or her work fully complies with the given specification and codes of practice.

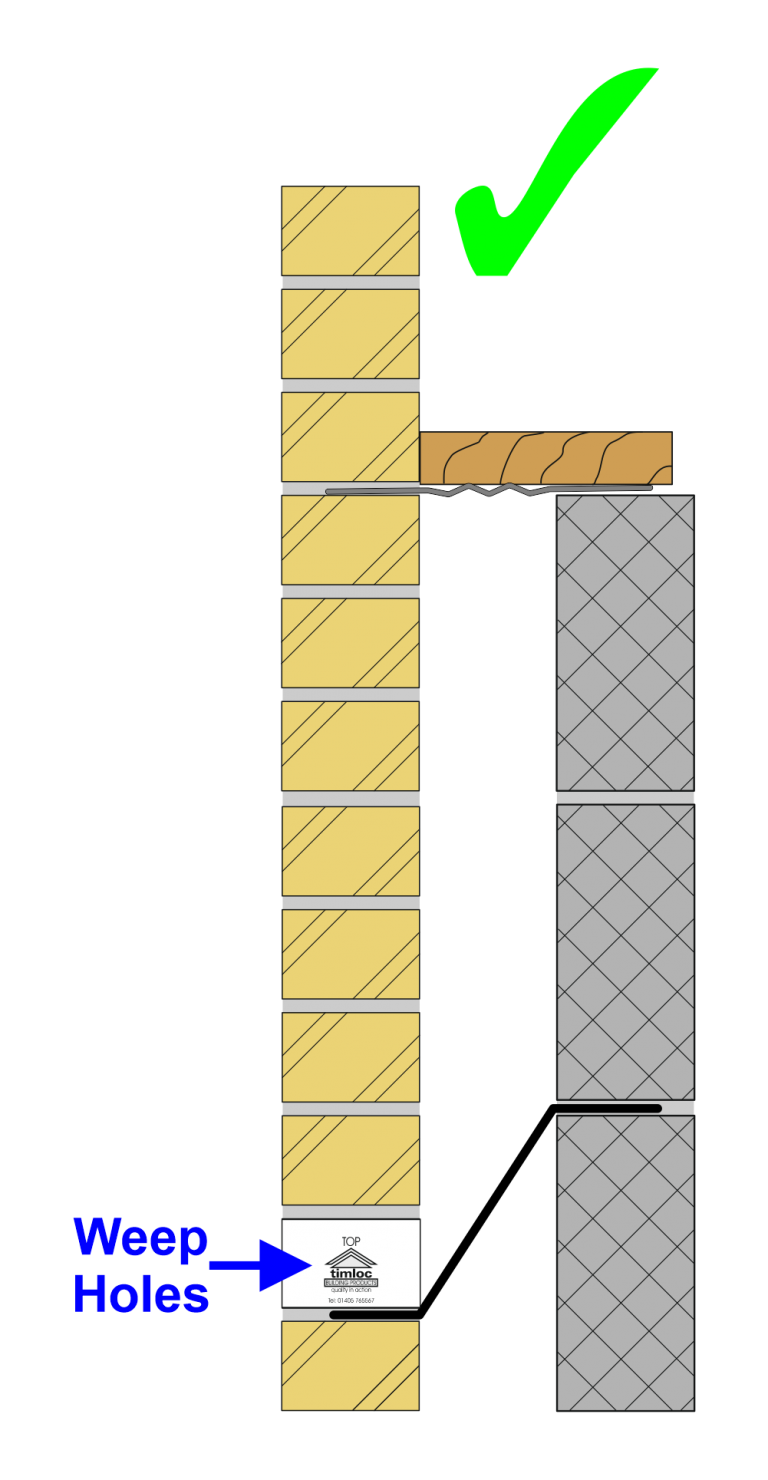

Wall ties should be placed 900mm maximum horizontally the vertical distance should be no more than 450mm horizontally in a wall with no openings in the cavity.

Cavity walls with openings should have a horizontal wall tie more than 150 mm maximum from the edge of the opening vertical spacings is no more than 225mm

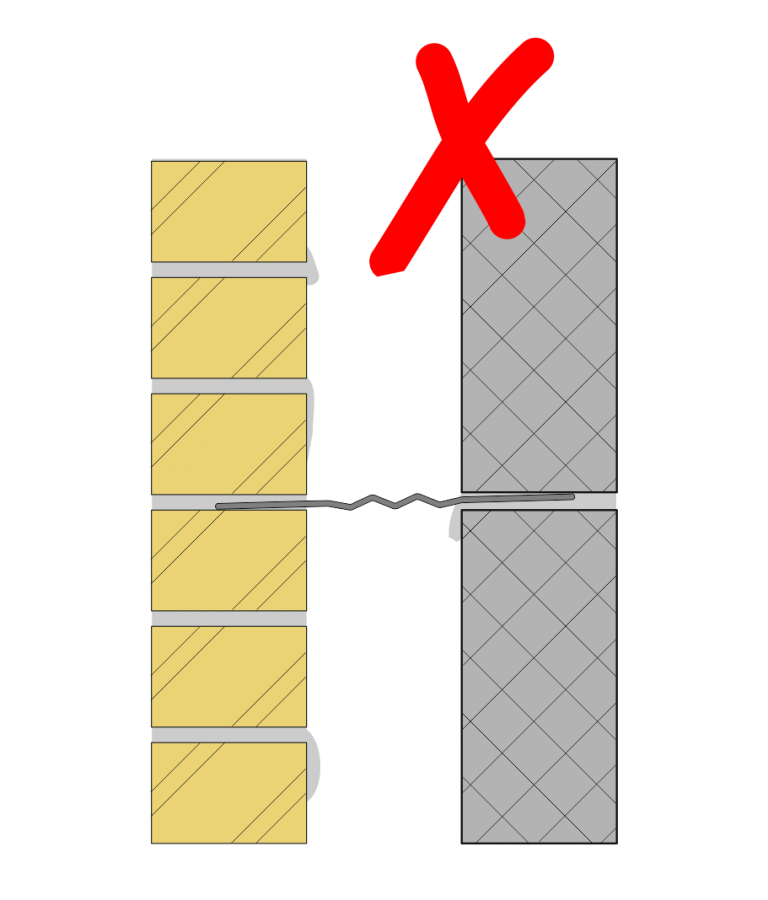

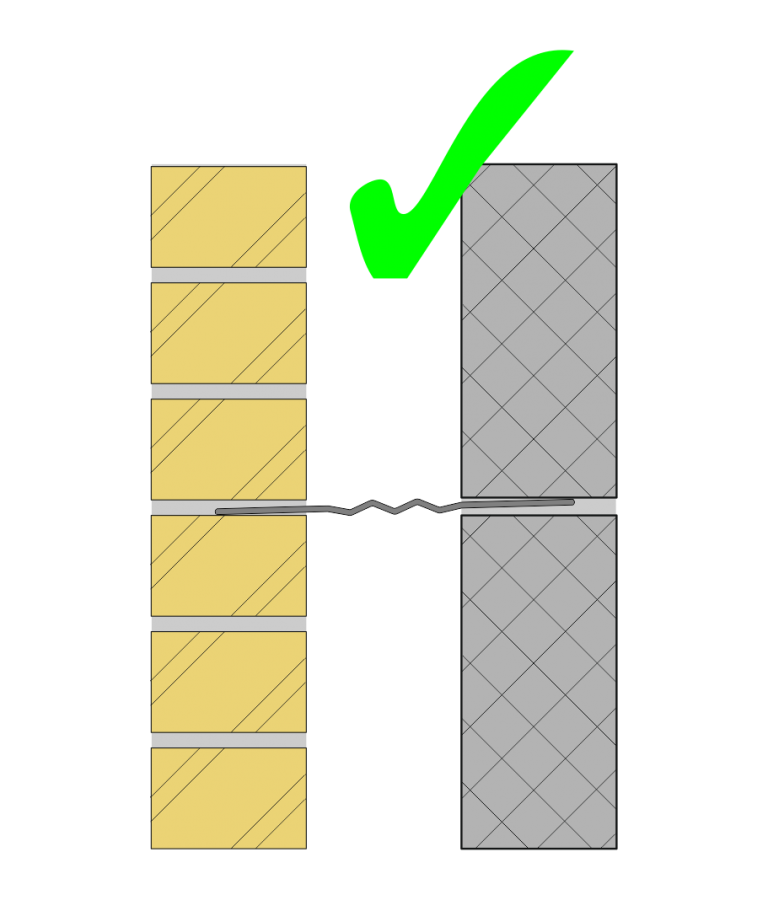

For strength, all ties must be bedded at least 50mm into each wall leaf and the tip of the wall ties should be in the centre of the cavity wall facing downwards.

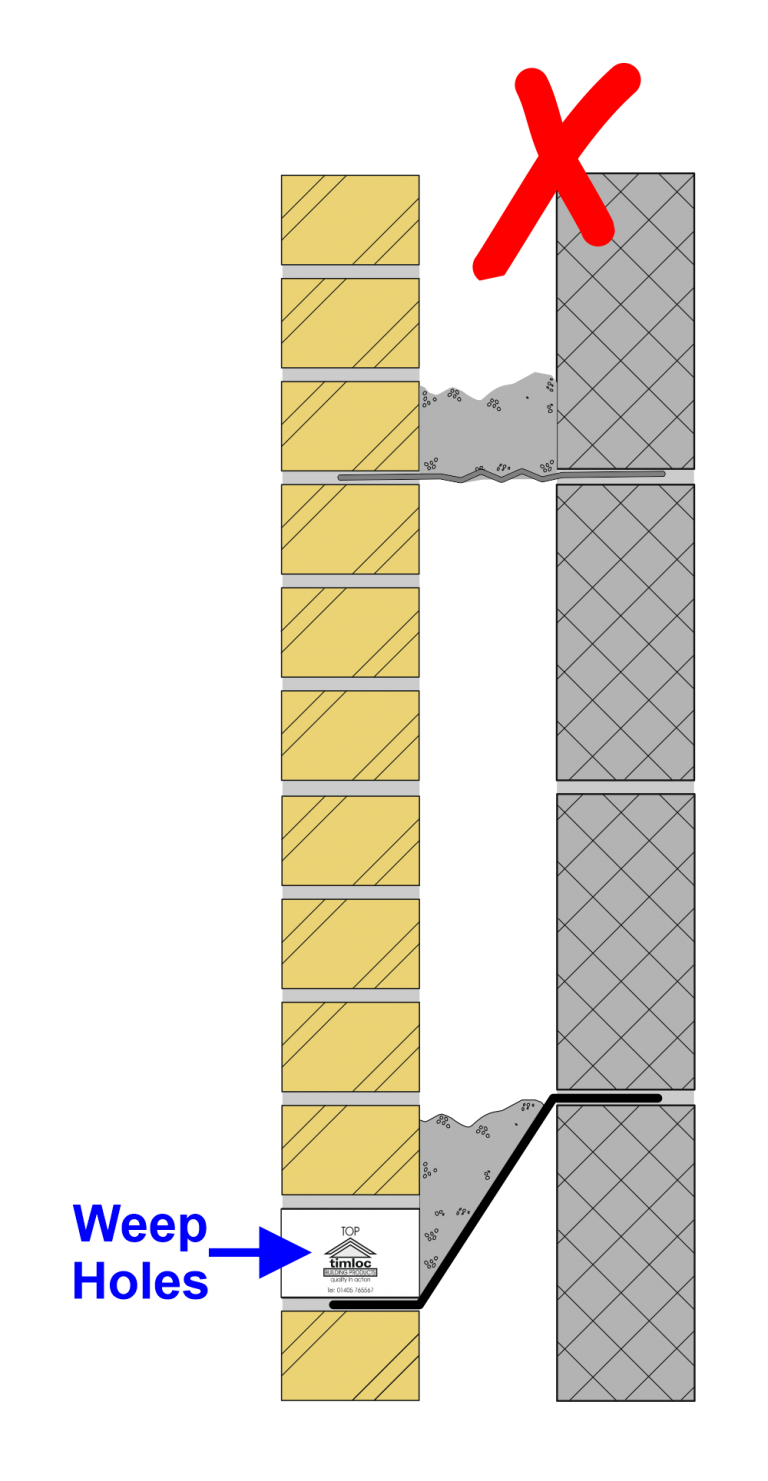

During construction, the cavity must be kept clean and do not allow mortar to build upon the wall ties, cavity trays or insulation especially on the top edge.

You can use a cavity timber batten which is supported by two wall ties this will help to keep the cavity clean especially when you are removing excess mortar from all joints inside the cavity as work proceeds.

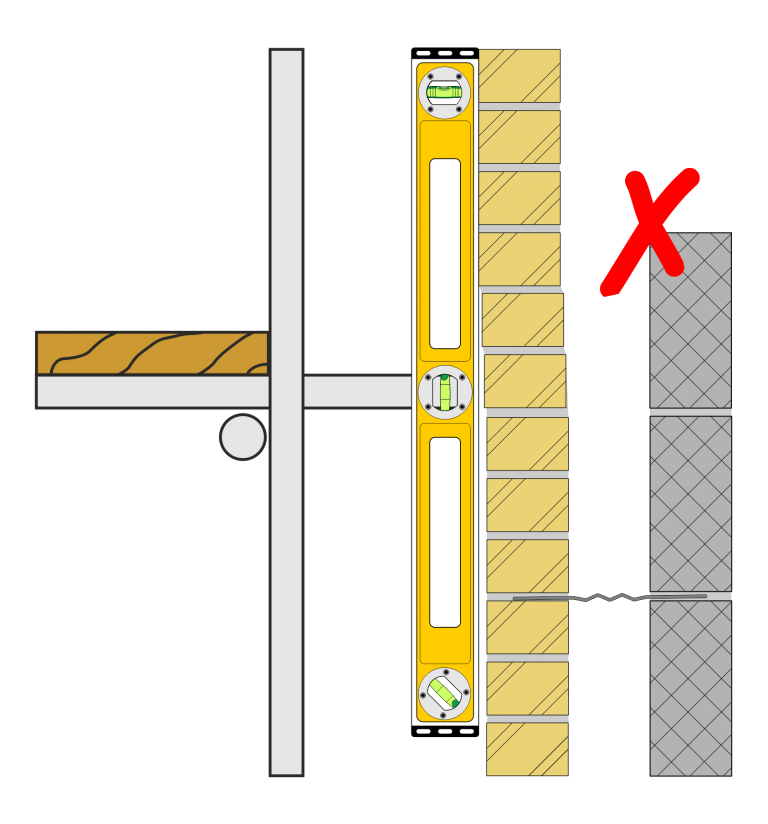

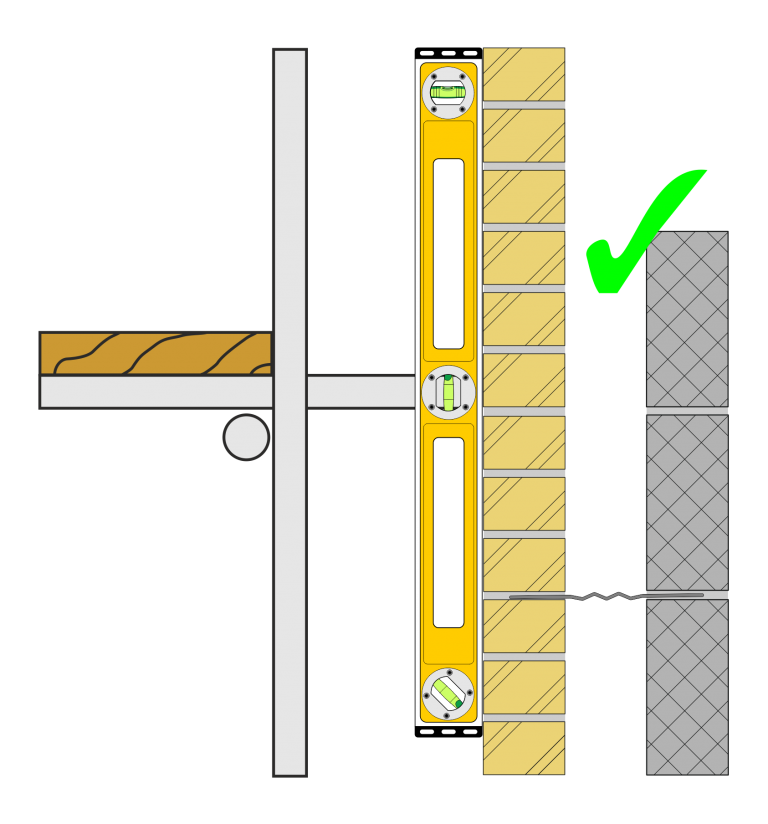

Bricklayers need to take extra care when building a cavity wall from one lift on the scaffolding to another lift, must ensure that they maintain the cavity width specified in the design.

The first lift of the scaffolding is normally 1875mm from D.P.C., and 24 courses of brick externally (min 1800mm from D.P.C.) before erecting the first lift of scaffolding.

The difference in heights between the two leaves of a cavity wall under construction can be up to 6 block courses, provided the ties are sufficiently flexible to ensure coursing is achieved without breaking the bond.

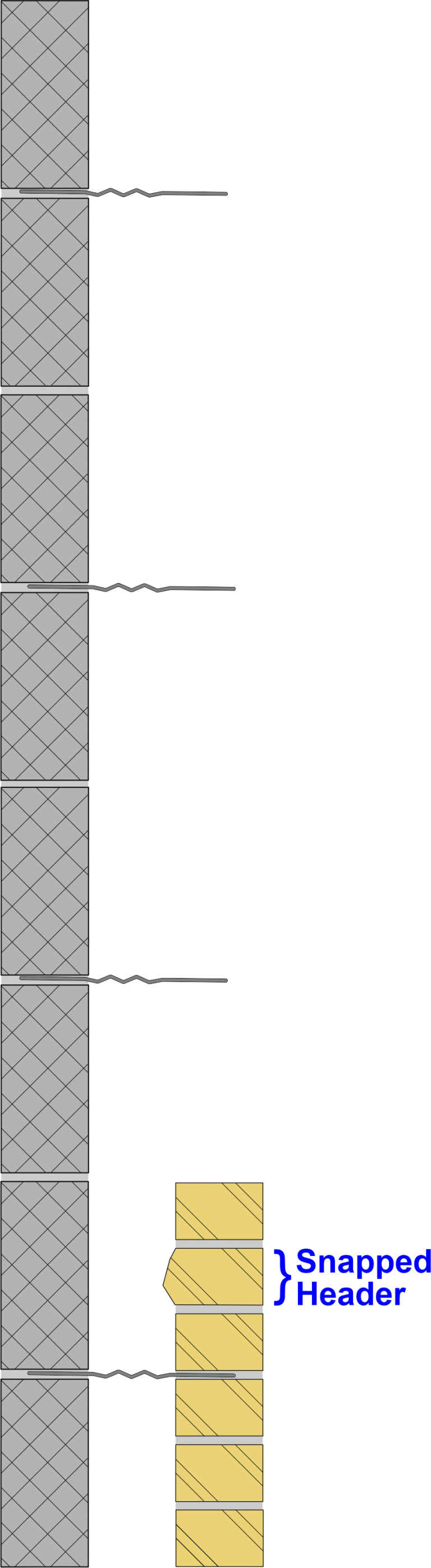

Avoid overhangs in the cavity like snapped headers if required should be accurately and cleanly cut

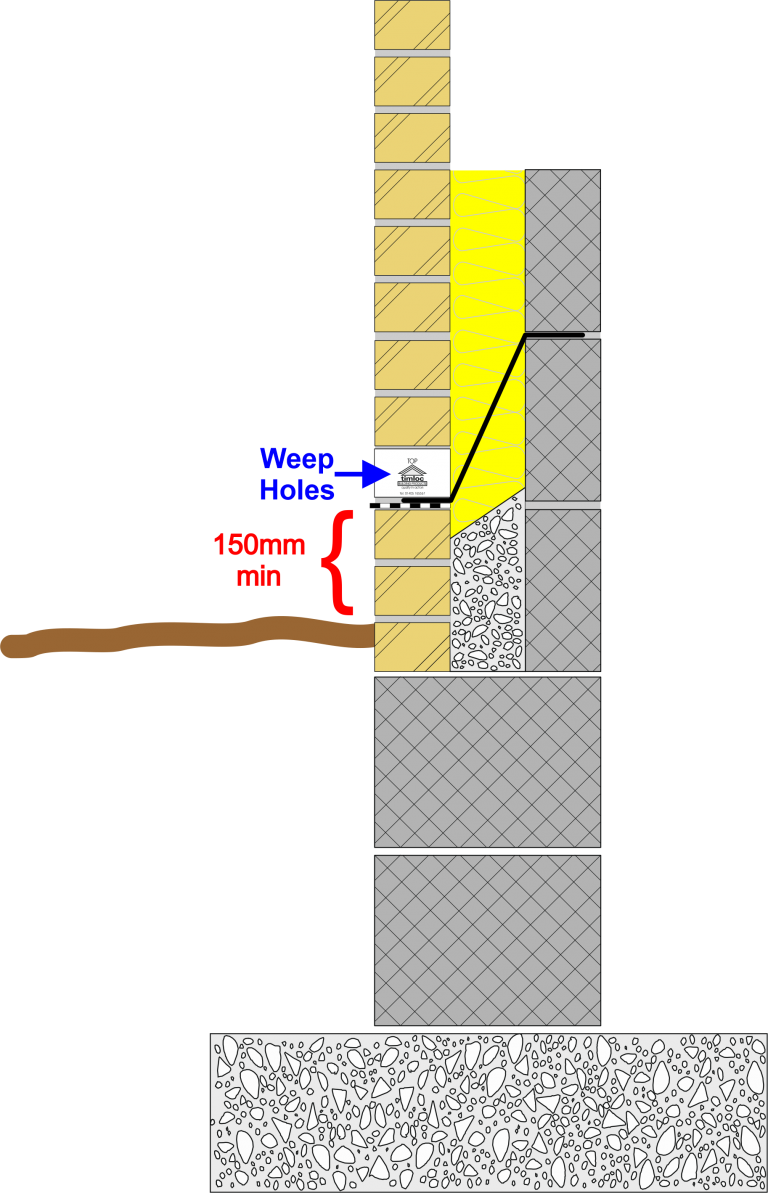

Horizontal D.P.C. is placed onto a bed of mortar not less than 150mm from the finish ground level.

The mortar joint on the underside of the horizontal D.P.C. should be flush and projecting out approximately 10mm and the mortar bed above D.P.C. jointed in

Any D.P.C. trays should be free from mortar droppings and un-damage during construction.

Weep holes on the horizontal D.P.C. tray should be free from debris and any mortar droppings.