Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

The learner can:

We know that levelling is achieved by transferring levels from a point of reference known as a datum.

The term levelling means transferring those levels to different positions on the site.

Levelling is all about establishing the relative heights of different points above or below the datum.

Ordnance Bench Mark

During construction, there will be several occasions when you need to transfer levels from a given point this will include the following:

· Excavation of subsoil (which is below the topsoil) to the required depth for the foundations.

· Horizontal DPC level and concrete floor level.

· Concrete paths and gradients.

· Invert Levels for Drainage.

· Heights of Walls, Windows, Doors, Floor Levels plus Lintel Heights.

Water Level

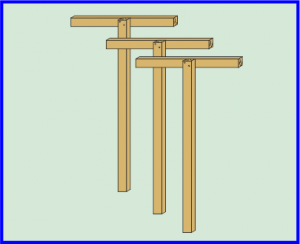

Tripod

Straight Edge

Wooden Pegs

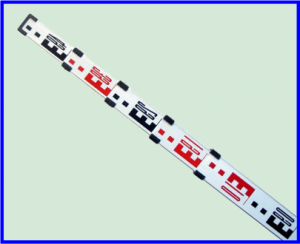

Graduated Staff Rod

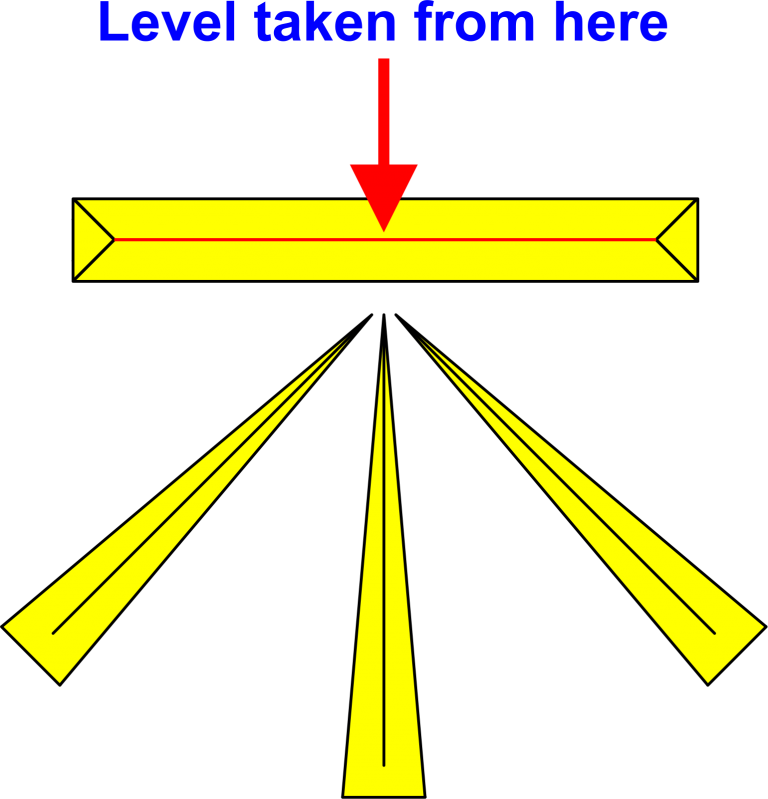

Boning Rods

Automatic Level

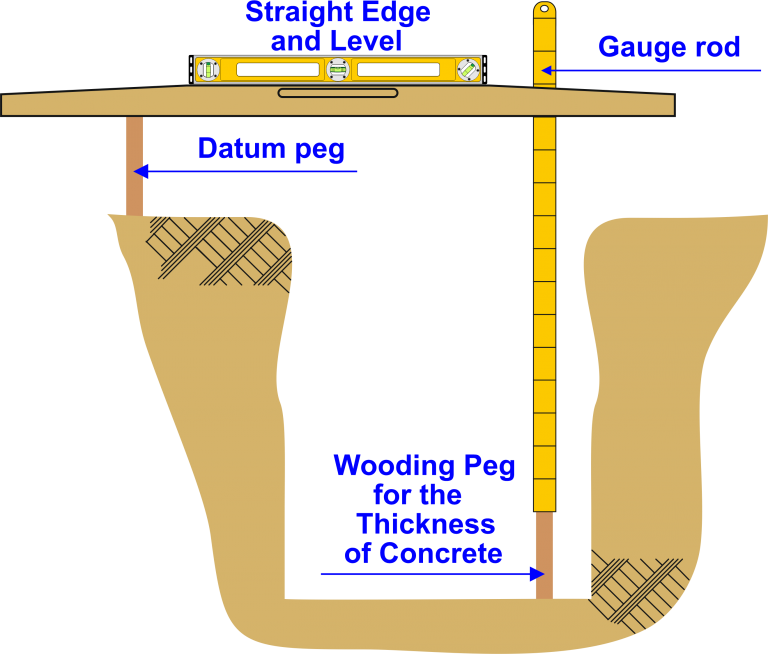

After all of the profiles have been positioned, the foundation trenches will be excavated to their approximate depth.

At this stage levels must be transferred from the datum peg to pegs positioned in the bottom of the trench.

These pegs determine the thickness of concrete foundation required and also assist in keeping the surface of the concrete level.

Whenever possible the difference in height between the datum peg and the concrete pegs should be a multiple of brick courses to assist the bricklayer.

After a level has been transferred to a peg in the trench bottom further pegs can be ‘levelled in’ using a straight edge and a Spirit Level, For further information please go to “Level and Straight Edge”

Transferred from the Datum Peg

Working size of Brick

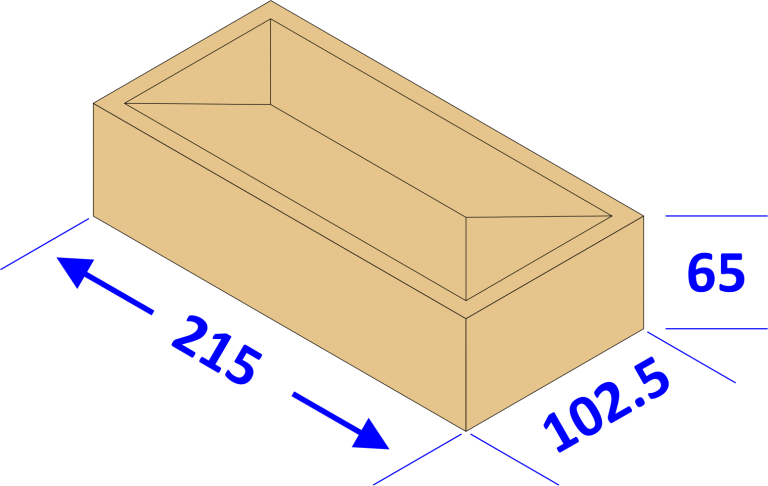

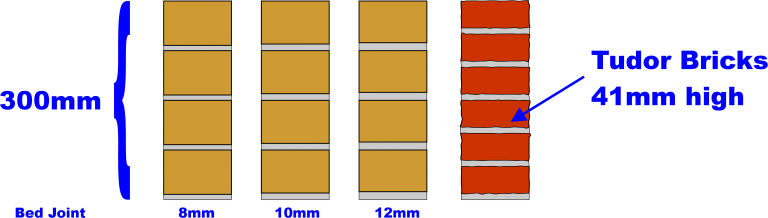

Working size of metric clay bricks is approximately 215×102.5×65mm, the size is not set in stone because the clay is a naturally occurring material and variations in drying and shrinking means that actual dimensions can vary.

Co-ordinating Size of the Brick includes the Bed Joint and Perp Joint approximately 10mm, this will depend on the working size of the brick.

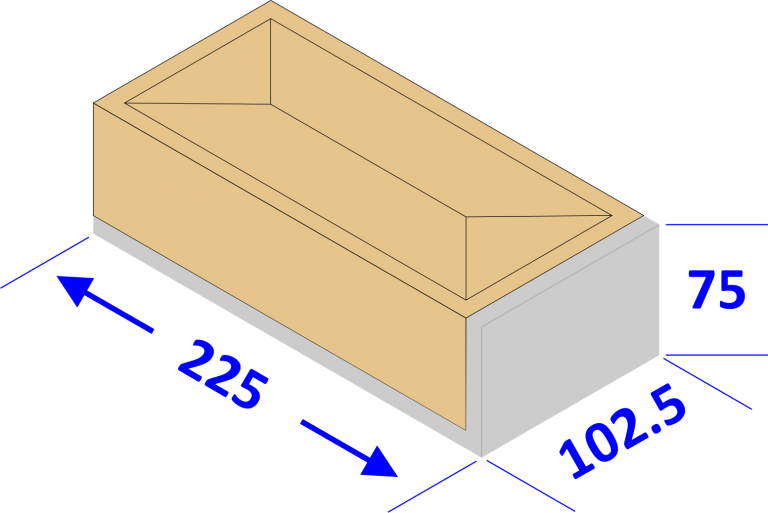

In most cases, you will have to adjust the bed and perp joints to maintain the height of 75 mm and a length of the brick 225mm.

Co-ordinating Size of Brick

Gauge rod

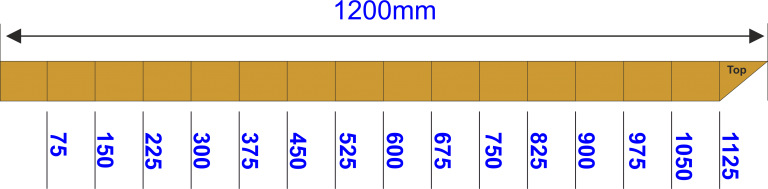

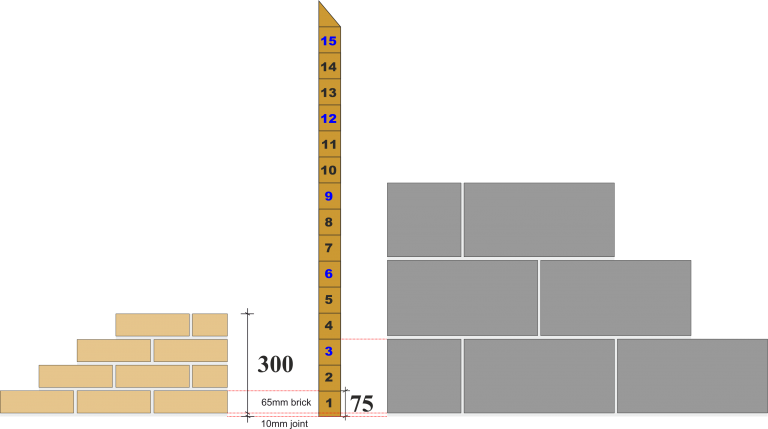

Gauge rods are normally made out of timber and marked out in Intervals of 75mm.

A standard brick co-ordinating height is 65mm with a mortar bed of 10 mm this gives you 75mm gauge.

When marking out a gauge rod, use running dimensions as opposed to multiples of 75mm for example below.

Marking out Gauge Rod

When marking out your gauge lines use a carpenter’s square, then make a saw cut which will last a lot longer as opposed to a pencil mark.

When marking out your gauge lines use a carpenter’s square, then make a saw cut which will last a lot longer as opposed to a pencil mark.

To ensure you used to gauge Rod the correct way up, cut the top of the gauge Rod at an angle.

You can mark the individual number of bricks and highlight the height of blocks as well, there are three courses of bricks to the height of a block.

Gauge rod

Using a Gauge Rod

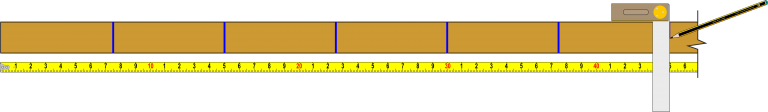

Specialist Tape Measure

You can purchase specialist tape measures designed to aid professional bricklayers when they are gauging brickwork or blocks.

The tape measure blade is similar to a normal tape measure, but it has additional information like the height of bricks and blocks in metric measurements which is accurate to EC Class I, for general measuring.

Using a Gauge Rod

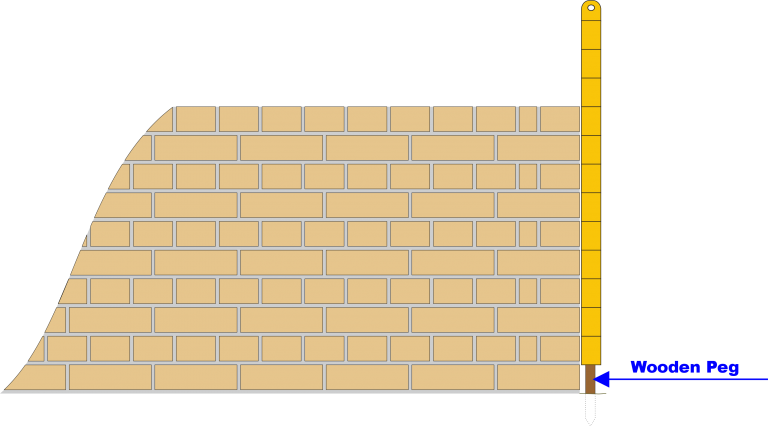

When using the gauge rod user at a fixed point like corners or the end of walls, you need to set a peg into the ground making sure the peg is upright and level.

An alternative method is to use an old Tingle plate or piece of metal embedded on top of the first course of bricks as a Datum point.

The above methods will help you to keep the base of the gauge rod free from mud which will affect your gauging, that’s why you never use a gauge rod from the ground.

Bedding Bricks to Gauge

When bedding bricks to gauge you will find that the working size of the bricks varies from the standard size.

Bed and Perps joints should be 10mm, this is not always achievable due to the nature of the natural clay which shrinks during the manufacturing process.

To achieve the correct gauge for example 4 courses of bricks equals 300mm you may have two open up the bed joint or squeeze down to achieve the correct gauge.

Old bricks like Tudor bricks have a height of approximately 41mm height when using these type of bricks you will have six courses to 300mm.

see the above example

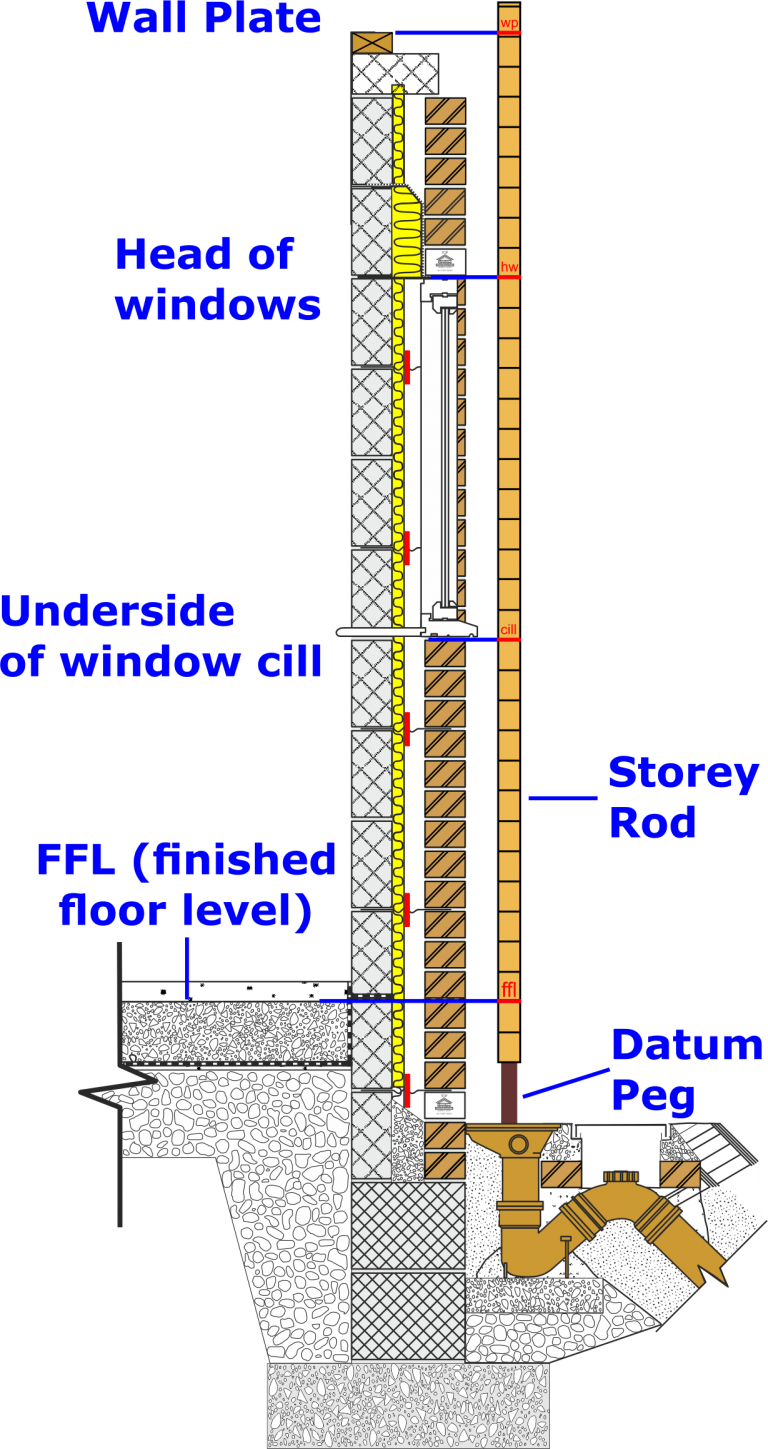

Using a Storey Rod

Story rod is made from a straight piece of timber which is cut to the height of the story which is the ground floor to the first floor, this ensures that all levels are constant across the floor area.

Working from the elevation drawings bricklayers will extract key points like the finished floor level, the underside of the window cill, the height of the window header so that they can build in the lintel at the correct level, wall plate being the highest point on the elevation.

The gauge of your brickwork should be in line with all key points from their elevation drawings, if there is a discrepancy see your supervisor or site agent.

Time spent checking the working drawing dimension before marking your story rod is essential to avoid costly mistakes.