Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

The learner can:

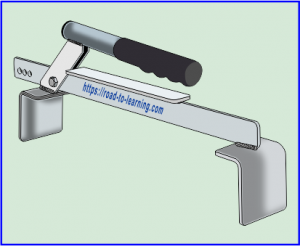

Brick Lifting Tong

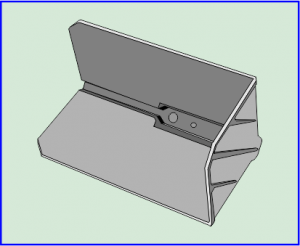

Hod Carrier

Wheelbarrow

Tin Snips

Cold Chisel

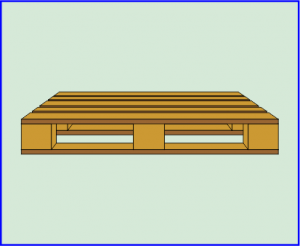

Wooden Pallet

Wooden Pallet

Tin Snips

Cold Chisel

Wearing the Correct P.P.E.

Personal Protection Equipment (P.P.E.) is needed before any blending of any bricks, plus tools and equipment to safely carry out this activity.

You will need a wooden pallet to stack the bricks onto, plus a Cold Chisel and Tin Snips to cut the banding around the bricks.

The bricks normally banded with metal or plastic banding under tension to provide support.

Care should be taken when cutting banding straps since it can spring up and cause damage or injury.

The straps are under tension you would need a cold chisel to lift straps away from the face of the brick enabling you to usual tin snips to cut the strap.

Brick strapping should be made safe immediately, this might mean that you cut the strap again at the base of the stack so doesn’t create a trip hazard and bundle the loose straps and remove it from the working area.

Do not use a Lump Hammer and Cold Chisel to break the straps, this will damage the face of the bricks and the edges (Arris)

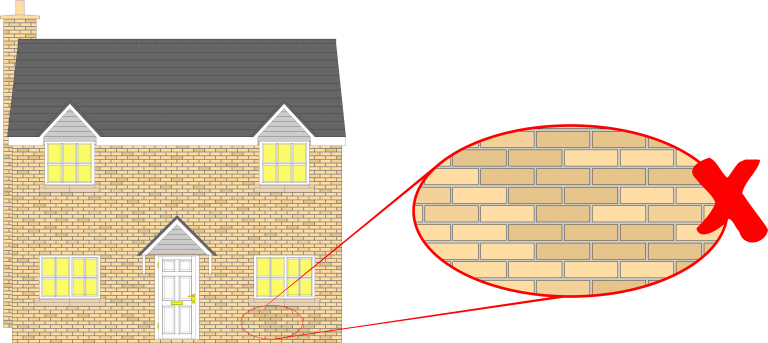

The blending of brickwork needs to be done due to the natural clay characteristics which have a variety of coloured shades when producing clay bricks.

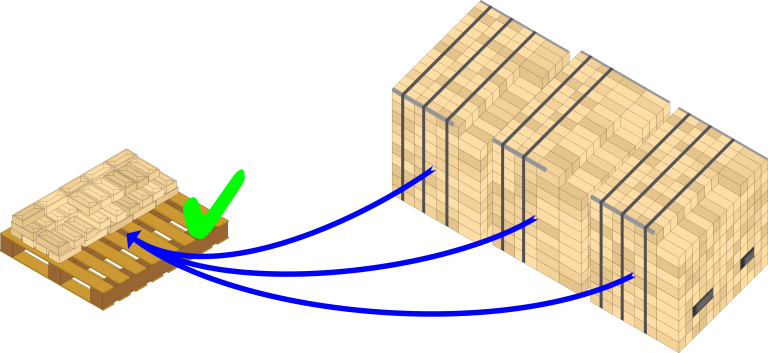

Manufacturers will blend their product into pallets, but you will still need to blend them on-site with a minimum of 3 pallets or follow the manufacturers instructions on blending.

Remember when removing bricks from the pallet work in vertical slices for the best blending.

You must order enough bricks for the job plus wastage to ensure you have a consistent batch from the manufacturers or builders merchants

The Correct Method of Blending with three Pallets of Bricks Min

The correct blending will avoid colour banding or patching within the face of the brickwork,

Ideally you should have an undamaged wooden pallet and carefully stacked the bricks together into a dry bond so that able to be transported across site by all-terrain forklift.

Remembering to handle the bricks with care to avoid damaging the surface area.

You will need to protect a new pallet of bricks against the weather conditions by using hessian to protect against frost plus waterproof sheeting to keep them dry ready for laying by the bricklayer.

Poor Blending of Bricks

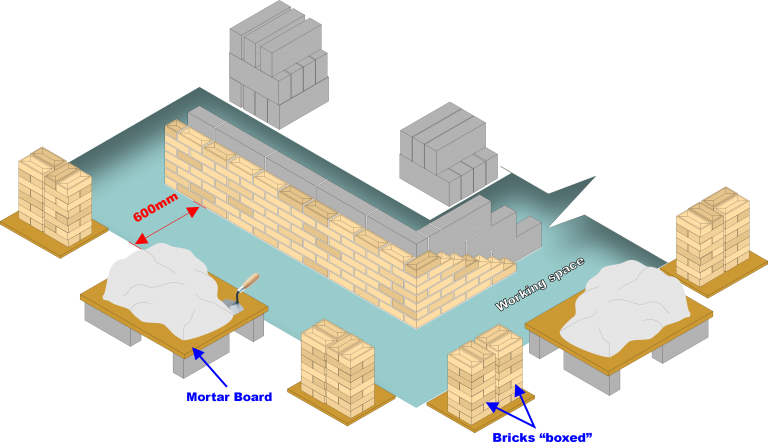

When loaded out the technician (Labour) needs to work out how many bricks per lift, the first lift is from DPC level to scaffolding height which is normally 1.8m high.

A technician loads out the bricks and mortarboards alternatively running along the face of the wall Leaving 600mm for the working area from the face of the wall to the materials.

Bricks stacked frog up and with the face of the brick away from the mortarboard

If you’re on the first lift which is from horizontal DPC level then you need to think about putting boards underneath of the brick stacks or blocks, to stop them absorbing water from the ground or contaminating the bricks or blocks.

Mortarboards normally 600x600mm and are placed onto concrete blocks on edge and the boards are whetted down so they don’t absorb all the moisture from the mortar mix which will weaken the mix and workability.

Bricks which are adjacent to the mortarboards must have the face of the brick facing away from the spot board this ensured that no mortar is splashed onto the face of the brick.

At the end of the day, all mortarboards are cleaned and placed on top of the brick or block stacks to protect them from the rain.

In winter extra precautions are needed against icy conditions you would need to protect your materials and your working area with hessian with waterproof sheeting on top ensured that it is weighted down.

Loading out Bricks and Blocks