Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

Pointing is the craft term used to describe the surface finish of the bed joints and cross-joints of a brick wall where the joints have been ‘raked out’ approx. 12 mm deep and filled with mortar of different colour, texture and sometimes density, from that used for laying the bricks in the wall.

Jointing is the term used when the mortar joints are finished as the work proceeds, and is usually done course by course.

Jointing

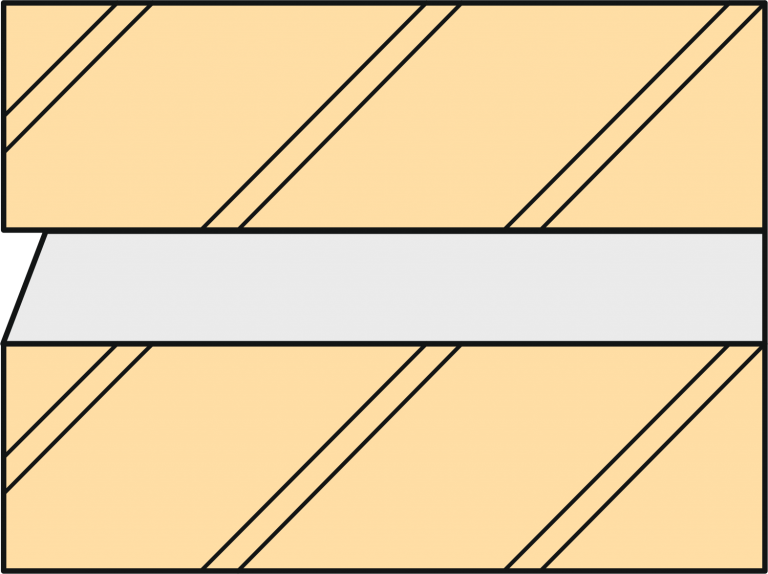

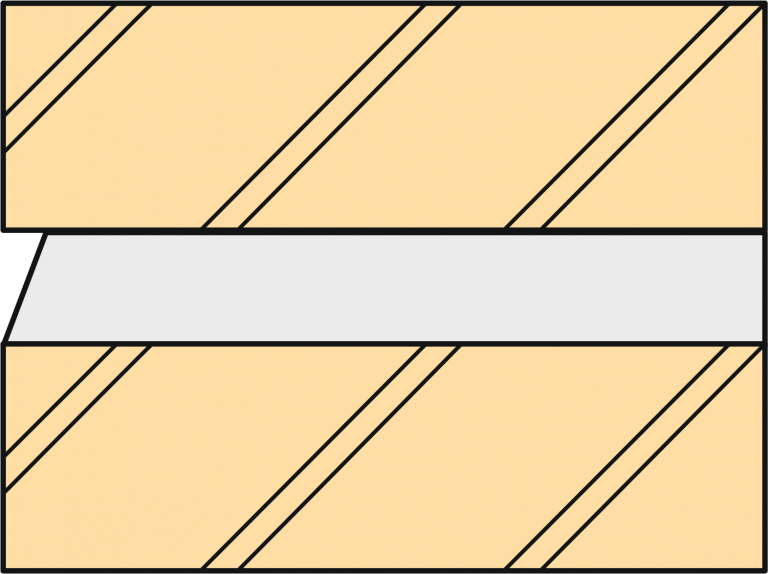

Weather Struck Joint

This is a popular method of finishing joints on external face work.

It gives protection against rain penetration as the slope of the joints runs water off the joint.

The upper edge of the joint is struck back with a pointing trowel.

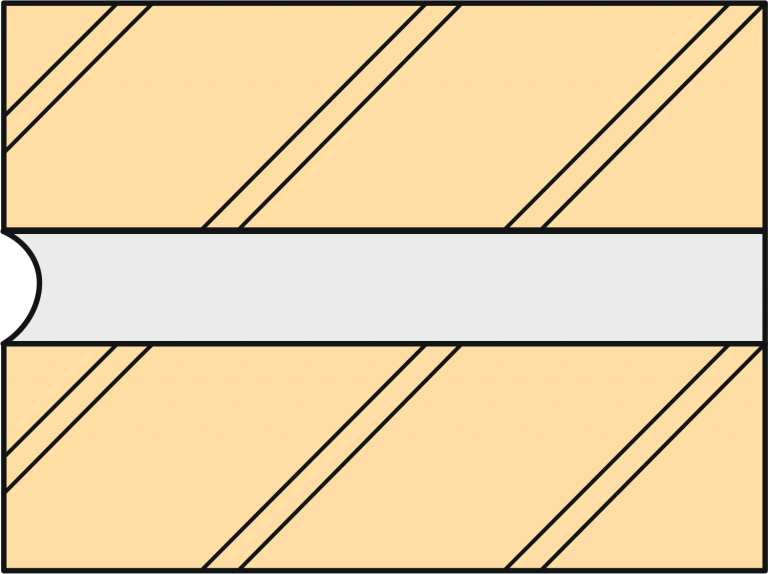

KEYED JOINT or “rounded” or “tooled” A concave finish is obtained by rubbing a suitably shaped tool over the joint.

The simple tool is often a piece of bucket handle or round mild steel. Mostly used for external work.

Keyed Joint

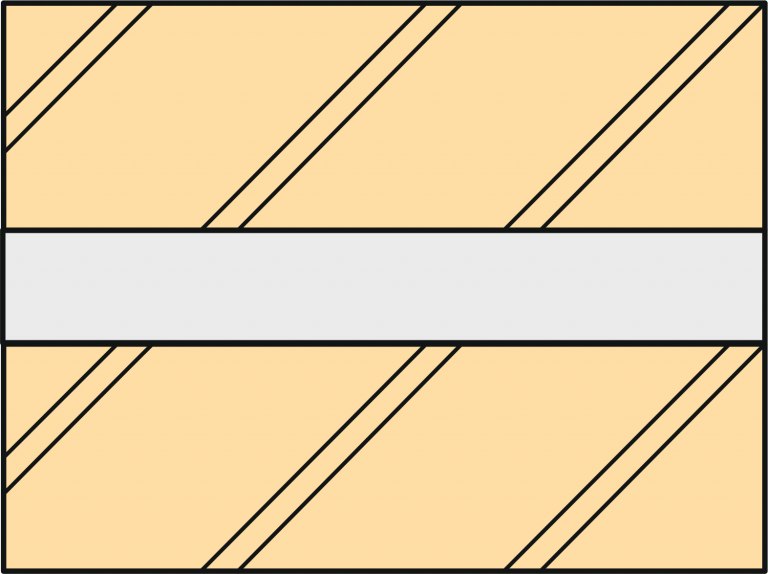

Flush Joint

The mortar is compressed into the joint and finished flush with the face of the brickwork.

It may be used for internal or external work.

The finish is obtained by rubbing over the joints lightly with a piece of cloth.

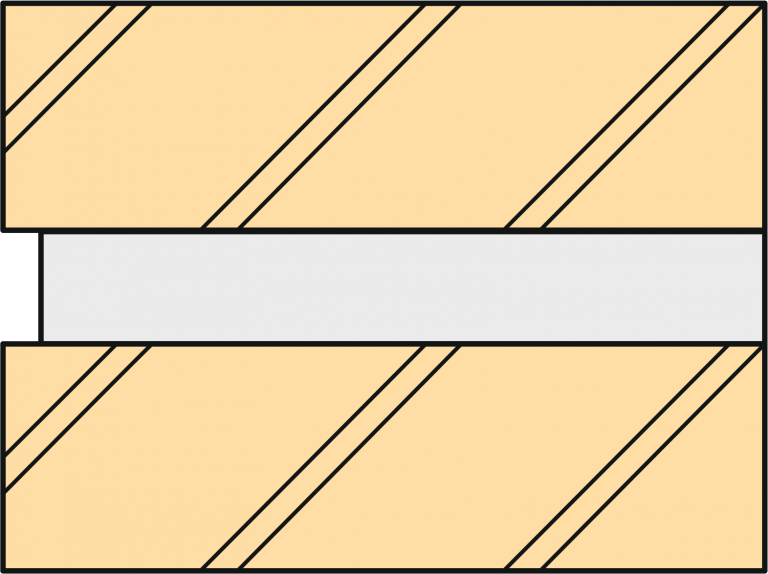

The mortar is pressed back firmly into the joint with a metal jointer or a piece of wood the exact width of the joint.

Square Recessed (Raked)

Jointing

The difference between ‘jointing’ and ‘pointing’ is that:

Jointing is finishing the mortar joints between newly laid bricks.

Pointing is applying a small amount of mortar into the face joint between bricks (either newly laid or in old brickwork).

Pointing

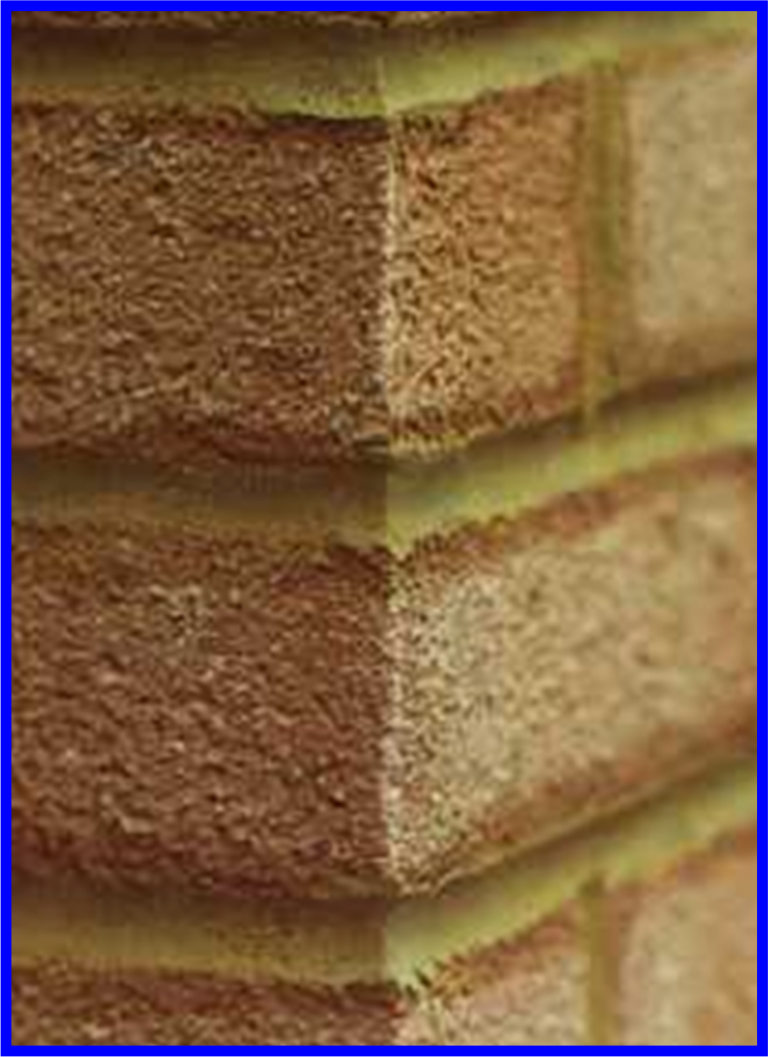

In new brickwork, pointing can apply harder mortar to increase weather protection on exposed faces.

In old brickwork, pointing is often used to repair mortar joints which have been eroded by exposure to the elements.

Styles of finishing

Whether jointing or pointing, the basic finishes are the same:

Many things will affect the outcome of your pointing, the main problems are:

• Excessive moister in the bricks

• Laying the bricks in the rain

• Very low temperatures when laying

• Very high temperatures when laying

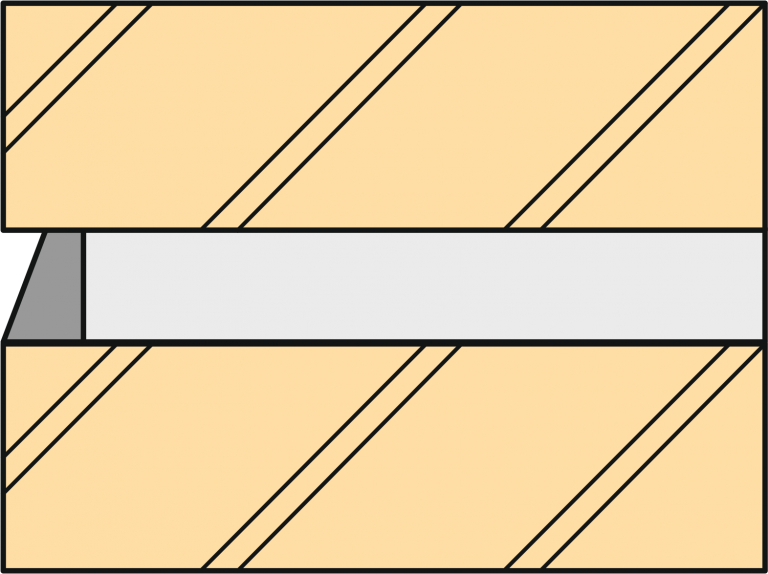

Internal jointing should not be straight

When finishing joints on internal angles, the joints must be made in such a way as to emphasise the bonding or tie bricks.

The finishing should be formed alternately to the left and to the right in alternate courses and not with a straight joint.

Care should also be taken at external angles, and also when jointing under projecting brickwork sills, under copings and on the underside or soffit of brickwork arches.

Internal Jointing Left to Right

Jointing is the bricklayer’s term for the action of finishing the joint faces of the bedding mortar as work proceeds.

It is the oldest method for finishing brickwork and was mainly executed using trowels until the early 17th century when jointing tools increasingly became standard.

It continued to be used for ordinary work and with the decline in craft traditions after the first world war, jointing predominated once again.

Jointing

Advantages

• Unified joint

• Uniformity of joint in strength and colour, provided mortar is accurately gauged

• Reduced labour costs

Disadvantages

• Less quality control of joint finish (not all bricklayers joint well)

• Difficulty in maintaining uniform colour throughout the wall face.

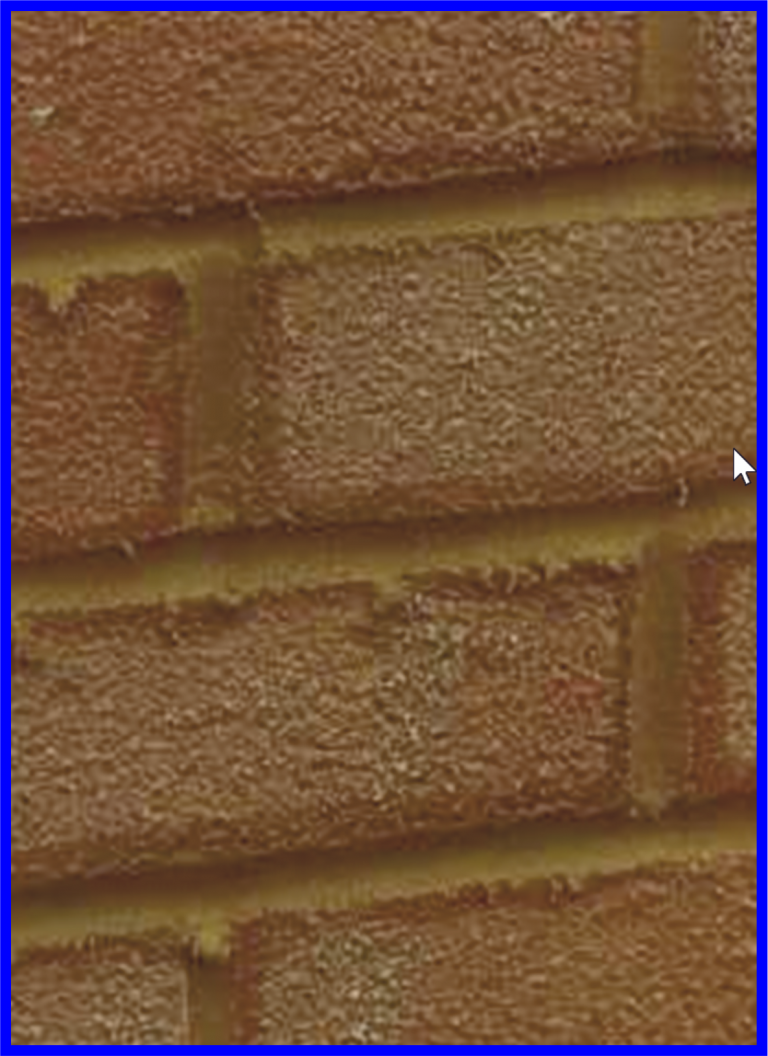

Repointing is the process of renewing the pointing, which is the external part of mortar joints, in masonry construction.

Over time, weathering and decay cause voids in the joints between masonry units, usually in bricks, allowing the undesirable entrance of water.

Advantages

• Superior joint finish

• Uniformity of colour and strength

• Greater choice of joint finishes

• Clean face work

Disadvantages

• Increased labour and material costs

• Additional construction time

• If incorrectly executed the compound joint may fail to unite

• Requires skilled and experienced pointers.

The quality of workmanship on site can have an overriding effect on the weather resistance of the brickwork.

Bricks should be laid on a full bed of mortar.

All cross joints and collar joints should be fully filled.

Immediately after the brick is laid, excess mortar should be struck off the external face of the work and off the internal faces of the leaves of cavity walls.

Care should be taken to ensure that the mortar is not scraped onto the exposed face of the brick.

Jointing late can cause a crumbled surface

Care Taken at Corners