Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Glasspaper originally manufactured by crushing glass into a fine powder, Sand was also used this where the name sandpaper comes from wrongly used.

There are several different types of glasspaper choose from some are made from natural materials like flint, garnet and emery.

Synthetic abrasives like aluminium oxide and silicon carbide both are tougher than natural materials and last longer the toughest one is silicon carbide.

Abrasives glasspaper comes in different lengths, sizes and shapes the most common one for small jobs are packets of various grade grit sheets, making it easy to take a surface from rough to finish.

P240

P100

P60

P40

Sheet Glasspaper

Palm Glasspaper

Belt Glasspaper

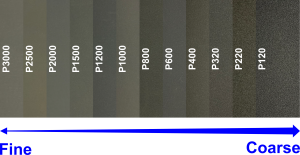

Glasspaper has a range of grit sizes are used to remove material from surfaces like old paint or sanding painted layer between coats to make them smoother.

Preparation for glueing requires the area to make the surface rougher with sandpaper to make a good contact surface for the glue

Grit size normally printed on the back of glasspaper with a letter P before the number, the number indicating the size of the grit.

P20 to P36

Roughing up surfaces ready for glue

P40 to P50

Removal of rough materials

P80 to P120

Preparation for finishing and for removing stains

P150 to P180

Final step before finishing

P220 to P240

Sanding Between Coats

General Caution

The wrong grit size glasspaper can cause more damage to the surface, for example, P60-grit glasspaper is the roughest glasspaper use on rough surfaces such as timber with dips, grooves and loose fibres.

After removing most of the rough surface you need to change a grit size to a slightly less abrasive, P60 to P80 by increase the glasspaper with successively higher grits to acquire a good surface finish.

This glasspaper has a waterproof backing so you’re able to dip into a soapy water container which helps to glides over the sanding area and eliminating the dust which is created by normal dry sanding.

Wet and Dry glasspaper is used between coats of paint to remove nibs, runs, or cissing to achieve a glass-like finish.

Paint cissing is where the paint is applied to a surface which is contaminated either by grease, oil, wax polish or silicon which leaves small craters of unpainted areas on the surface.

The Wet and Dry grit size is printed on the back for easy identification.

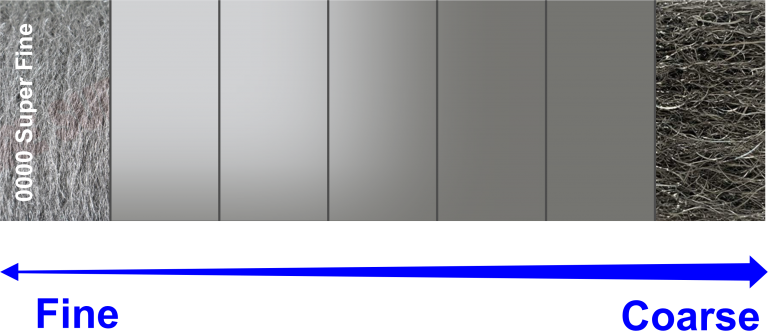

Steel wool very similar to fine grit glasspaper It’s used to remove ultra-thin layers of paint or varnish.

Instead of grit size, steel wool comes in 8 gauge sizes between 0000 to grade 4 being the coarsest.

The advantage of steel wool it can mould itself around most timber shapes where it’s harder to reach with normal glasspaper.

0000 Super Fine

Cleans windows without water or cleaners

Smoothes varnish before the final coat

Baffs furniture wax and turns gloss paint to a matte finish

000 Extra Fine

Removes paint spots from furniture and prepares surfaces between coats of varnish

00 Very Fine

Repairs varnished surfaces

0 Fine

Cleans grout between tiles and copper pipes and joints

1 Medium

Prepares wall surfaces before painting

2 Medium Course

Removes of varnish from surfaces using varnish remover

3 Course

Remove paint and varnish from floors

4 Extra Course

Use for heavy-duty stripping of paint and varnished