Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Where aggregates are not stored in overhead bins, they should be stored on clean hard bases that permit free drainage.

Care must be taken that cross contamination between different sized materials does not take place.

It is good practice not to store sand which is to be used in mortar production next to coarse aggregate.

Attention should be given to potential contamination from overhanging trees, especially when the material is stored for extended periods.

During cold weather it is advisable to cover sand stockpiles to prevent the material from freezing, especially if it is intended to use is in the early hours of the morning when any ice particles will not have melted.

Sand is often referred to as a fine aggregate.

It is normally dug from a pit or a quarry and should be clean and free from impurities.

Sea sand contains salt, which will adversely affect the mortar and should not be used unless it has been washed and supplied by a reputable firm.

Good mortar sand should be well graded so that it contains a mixture of fine, medium and coarse particles.

What is building sand?

Builders sand is a sand aggregate made up of decomposed rock.

The grains of builders sand usually sit between 1.5mm and 2mm in size, and vary in colour depending on where the builders sand is sourced.

Builders sand can very from light grey/white to reddish or yellow in hue.

What is plastering sand?

Plastering Sand is a fine textured, clean-washed sand that is primarily used for both internal and external rendering applications.

Providing a smooth finish, plastering sand is washed to reduce the risk of salt stains and ensures atmospheric moisture is not absorbed.

What is MOT Type 1 Sub-base?

MOT Type 1 Subbase or just Type 1 Subbase is a granular crushed aggregate.

It is used as a sub base in construction work.

Aggregate material is crushed to 40mm down to dust.

This mixture of sizes makes it great for compaction, making it extremely strong with great loading bearing qualities.

What is sharp sand used for?

Sharp sand is commonly used when laying paving courses, such as driveways, paths and patios.

When paving, the sand needs to be salt-free to avoid the paving slabs that lie on top of it being eroded and damaged.

It’s also desirable to use sand that provides good drainage.

Kiln dried sand is very dry fine sand that contains no moisture.

The sand is used to fill the joints of block paving and paving slabs.

By filling the joints with dried sand you keep the structure of the paving rigid and strong.

It also stops the ingress of water & stops the paving from moving and becoming loose.

Cast-concrete pavers are available in a variety of colours, styles and shapes, Standard brick paver size 200x100x50mm Approximately.

Textured setts are ideal for non-slip garden pathways.

Brindle concrete blocks are often used for drives and parking areas.

All pavers need a retaining edge to stop the pavers from shifting around especially if you have heavy traffic.

Unless the brick pavers are against an existing wall, you will need to put retaining edges in place.

Retaining edges have a function as well, during construction the edges can be used as level guides for preparing the screeded bed.

Brick pavers need a substntial edging set in concrete with Front and Rear Haunching.

Timber edging with pegs is not men enough especially when you are using the compactor plate during construction.

Below there are some examples of retaining edges.

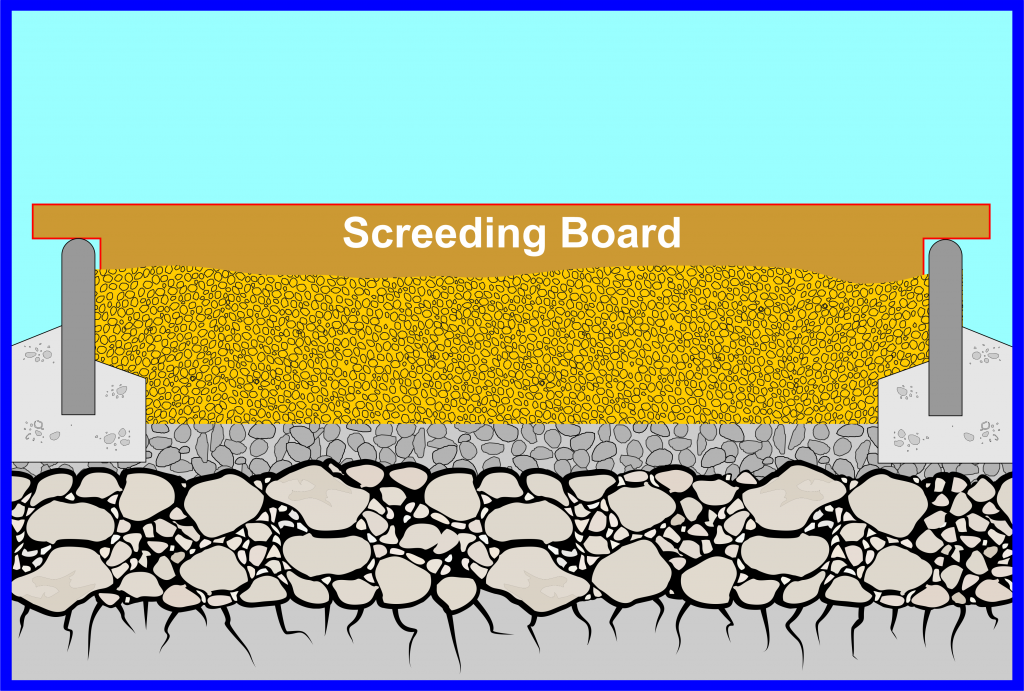

The function of screed rails is to producing a true plane surface in small bays to the length of your Straightedge or Screed Grading Tools

Screening rails can be made out of wood or metal and even other screeding levels like edging stones or kerbs.

Whichever materials you use for the screed rails you need to be strong enough and straight without any warping or twisting otherwise, they can leave undesirable ruts or high spots on the surface.

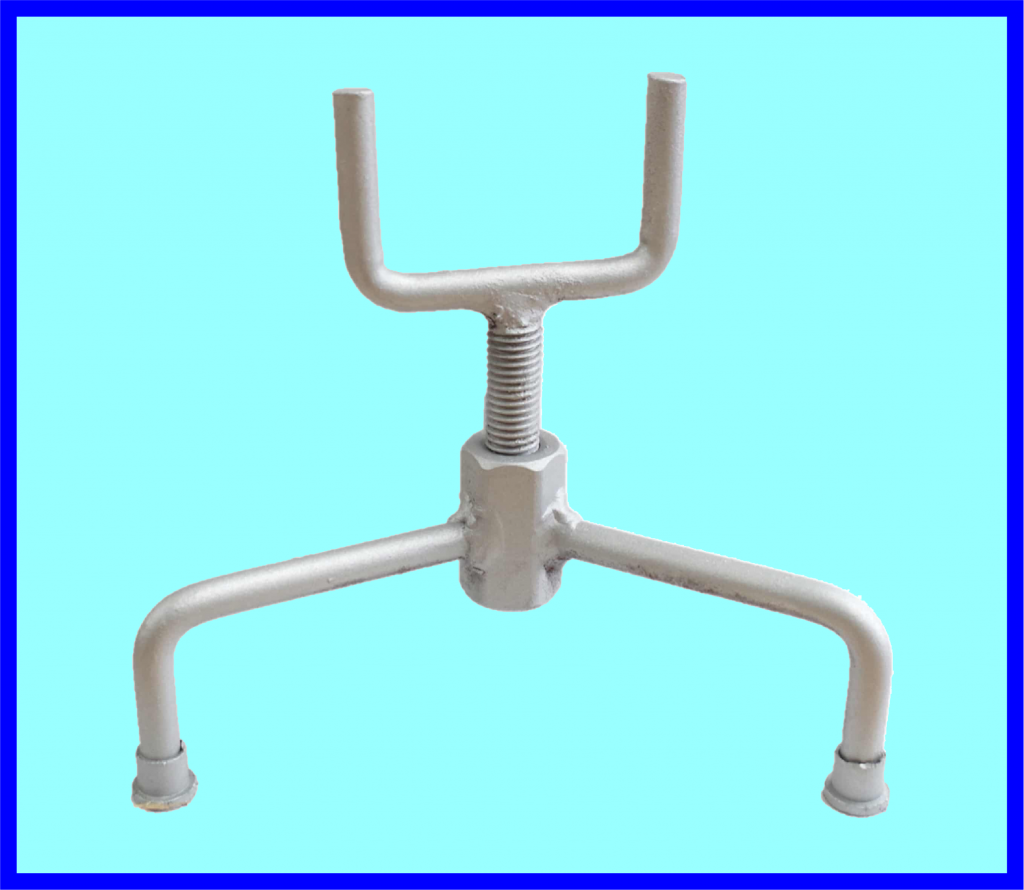

Screeding rail can be bedded to the required height or use adjustable screeding chairs which are removed on completion of the screeding.

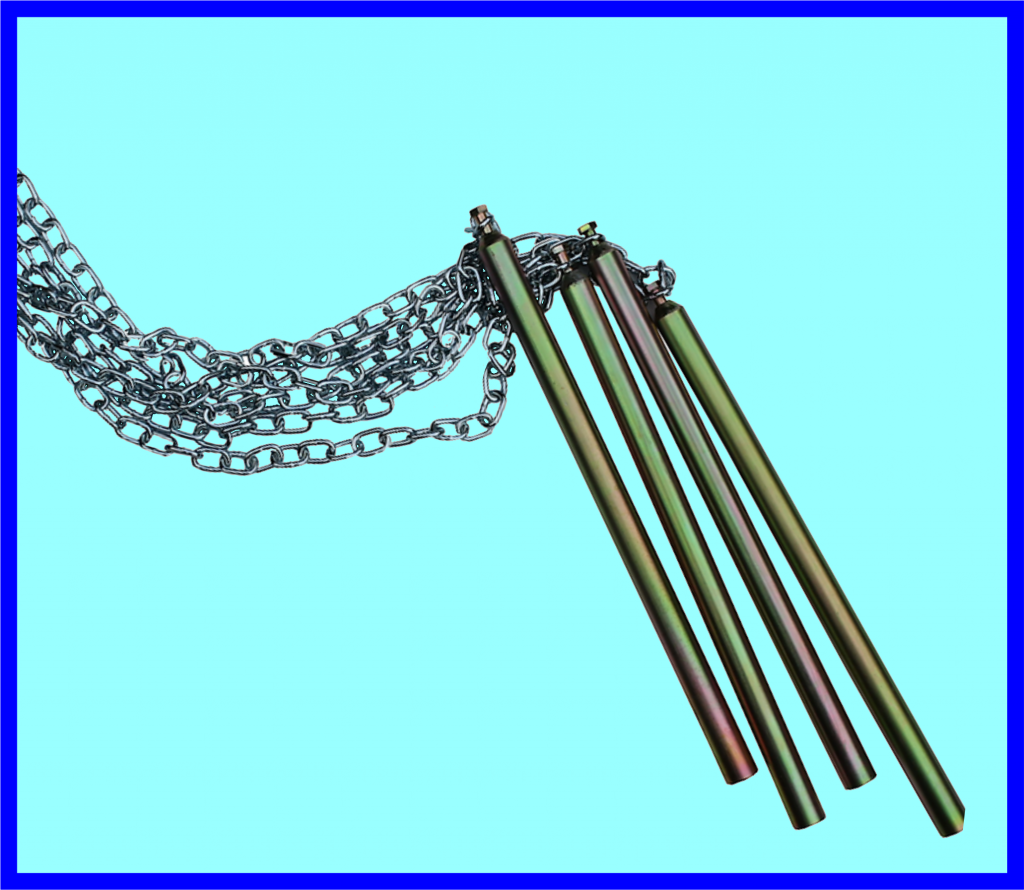

Path screeding rail poles we use mainly for pathways normally come in a set of four poles with the chain length set no more than a length of Screed Grading Tool.

When using levels like edging stones you need to cut a notch at both ends of the screeding board to the required depth of the sharp sand screed.

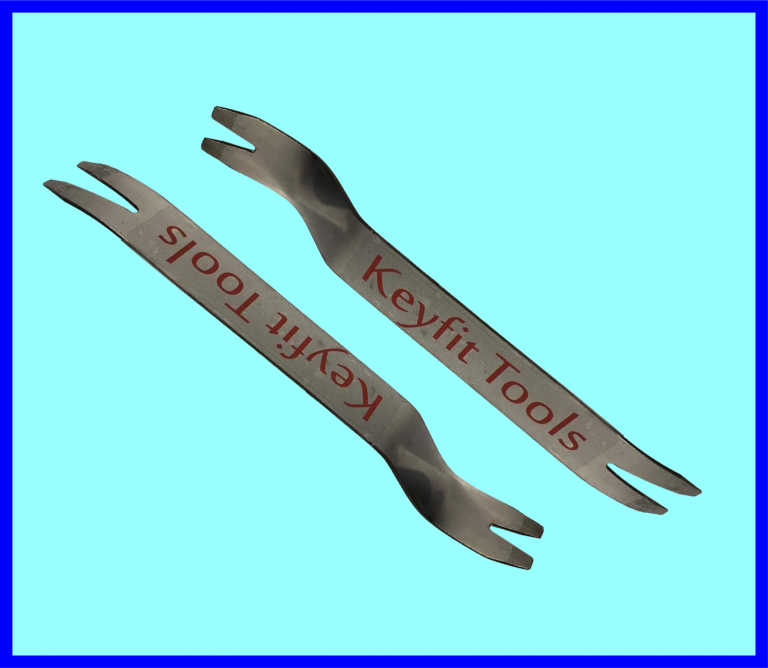

Keyfit tools work on the same principles as 2 flathead screwdrivers, simply place the Keyfit tools or screwdrivers (flathead) at each end of the paving block to be removed.

Make sure that you placed the tools in the joint as far as possible, then push both in an outward direction so that the paving block rises to enable you to pull it out the rest of the way by hand.

A rake is an essential tool to move excess material around the working area before using a screed grading tool.

The Tarmac Rake is larger than the normal garden rake which can have a head up to 36 inches and two heads with a longer handle.

One side of the head has oversize teeth that can easily rake through the sub base and sand on the opposite side has a smooth side of the rake head allowing the material to be levelled to an even surface.

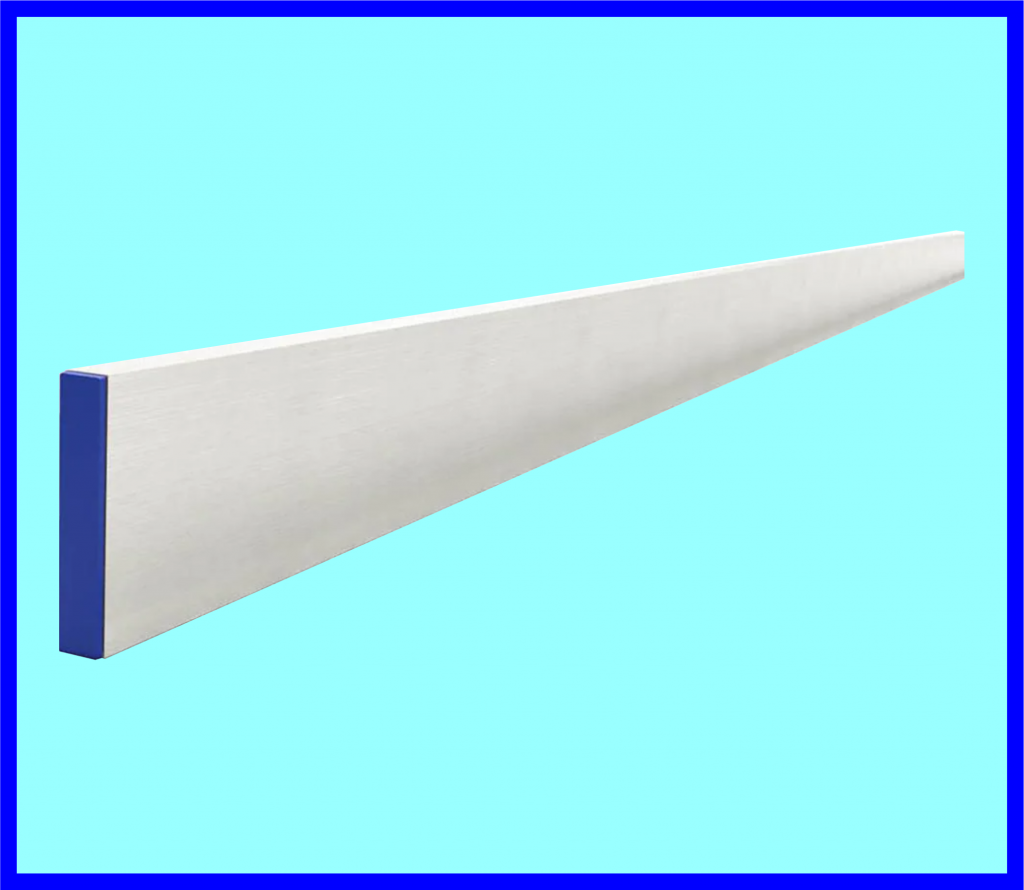

After using your rake to get the majority of the material level with your Screeding Rails, you can either use an Aluminium straight edge or screed grading tool.

The straight edge can be operated by a single person on larger bays you will need two people and teamwork is an essential part of getting the job done, this takes practice.

Starting at one end you draw the straight edge towards you removing excess material down to your Screeding Rails, this may take several passes don’t try and do one big pass.

The special design of the Screed Gauging Tool profile does not leave the screeding rail even when working with large quantities of screening material.

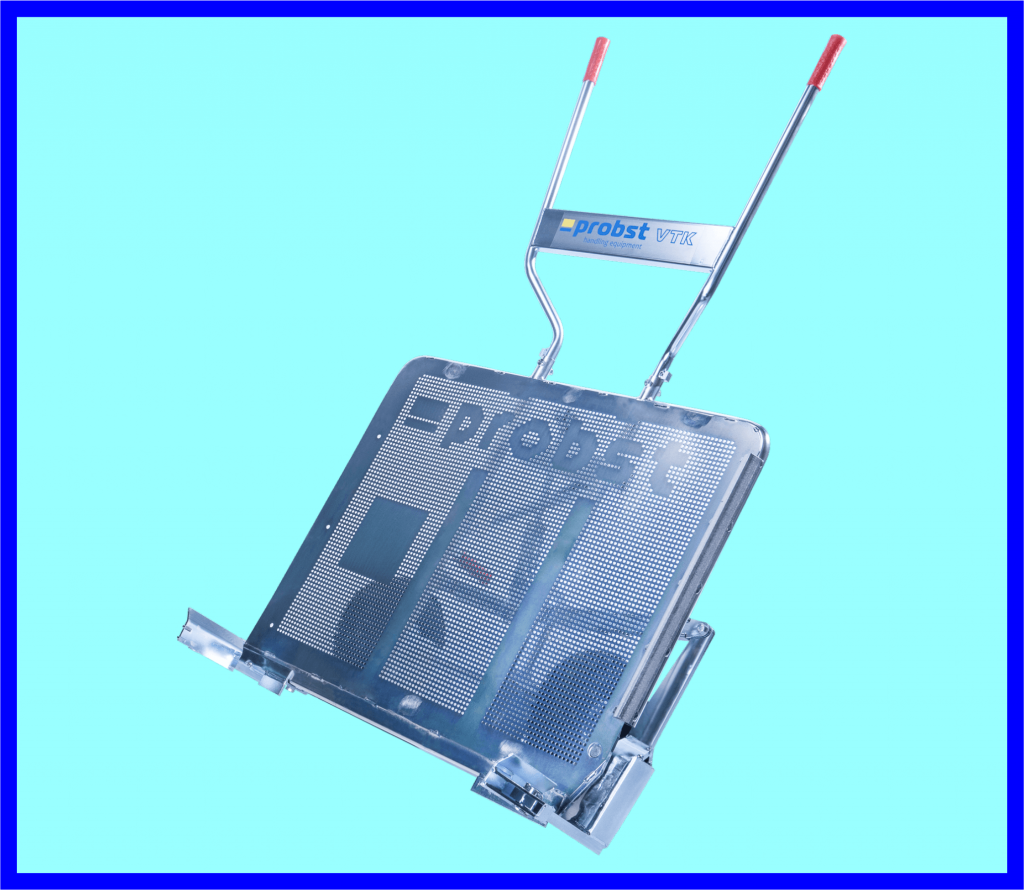

Before transporting pavers all workers should be trained in good handling techniques and the right equipment to use, this can be done in a Toolbox talk.

A common method is to use a wheelbarrow which can hold between 20 and 50 bricks, only problem is unless the route is flat and level with no bumps you can damage the pavers.

The ideal solution is to offload a pack of pavers close to the job enabling you to use other handling equipment there is a selection below.

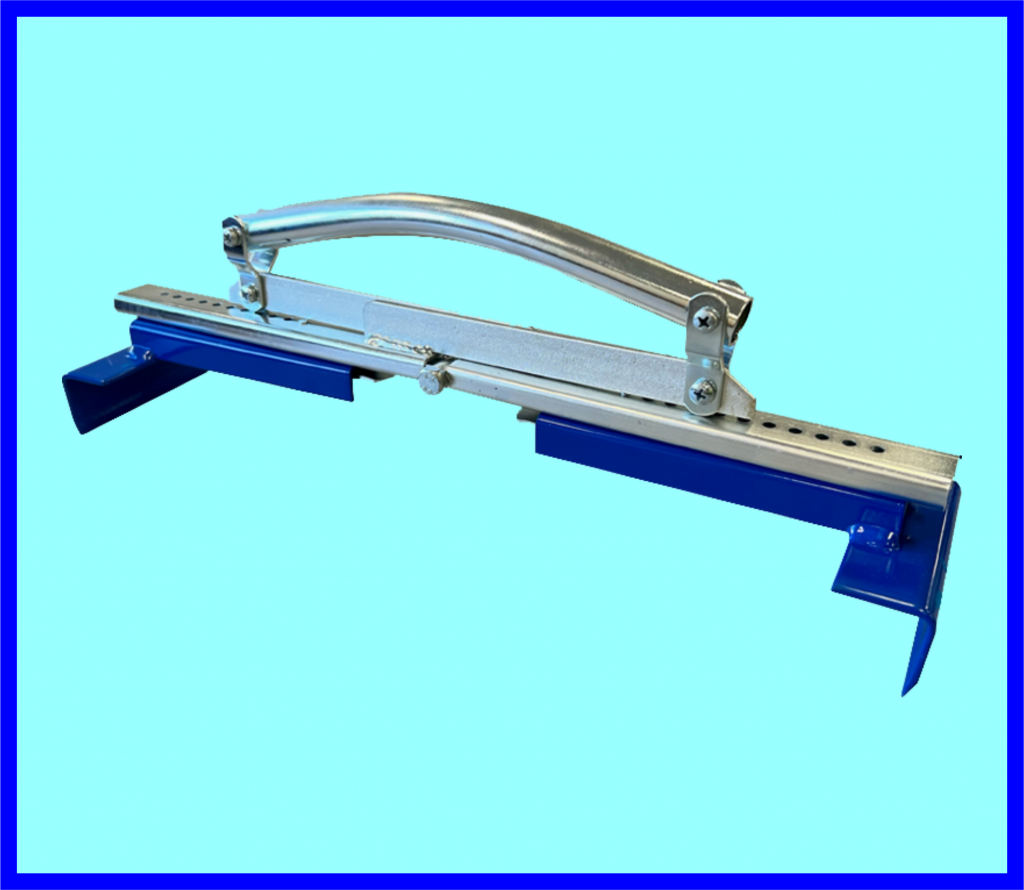

Extracting already laid paving blocks can be challenging if you haven’t got the right tools, there are several paving block extractors in the marketplace there are a few examples below.

Most of the Paving Block Extractors are adjustable to suit different sizes of the paving blocks.

Another alternative is the Keyfit tools Paver Puller will not work if your pavers have been permanently set to each other or to the base with adhesive or concrete.

Keyfit tools work on the same principles as 2 flathead screwdrivers, simply place the Keyfit tools or screwdrivers (flathead) at each end of the paving block to be removed.

Make sure that you placed the tools in the joint as far as possible, then push both in an outward direction so that the paving block rises to enable you to pull it out the rest of the way by hand.

Manually cutting paving can be done with a hammer and bolster, a better solution is to use a brick paver splitter which can be manually operated or powered assisted.

By splitting the brick paver you do not create dust as the masonry saw, and no need to change a worn-out blade on a regular basis.

The Brick Paver Splitter service life makes a block paver splitter the best choice for the environment and also your pocket.

When you’re cutting concrete pavers or blocks you need to take several important factors into consideration.

Hand-held saws like angle grinders are, potentially, extremely dangerous, one slip can slice through your steel toe caps, a better solution is a Bench Saw or Chop Saw.

You need to be trained and competent to use some cutting equipment.

You need to be aware of silicon dust and the precautions to take like wearing the correct P.P.E.

Is the cutter fit for purpose in other words has got the right type of blade and is the blade deep enough to cut through in one pass?

Below there is a selection of masonry saws

A compactor plate (wacker plate) it’s essential to ensure that the sub-base and sand are well compacted before placing any paving blocks down.

Depending on the job and the step of the Sub-base will determine the type of compactor plate you will need, there are a few examples below.

For most interlocking block paver jobs a vibratory plate with a compaction force between 13 and 22KN should be sufficient

The plate should pass over each area of blocks 5 times, compressing each area from a different direction each time it passes over.

Sometimes you need to compact areas where a compactor plate or jumping Jack cannot access special round posts or small areas.

A Hand compacter comes with a Weighs 4.5kg head with a square footprint of 135mm supplied with a wooden handle.

Using the Hand compacter by lifted vertically and then drop onto the same position compacting the material through impact.

As each brick paving course is established is good practice to use a Rubber Hammer on each course ensuring a tight fit between each paver.

The final alignment is done with an alignment bar and a set of string lines to establish a straight line between two given points before compaction.

Additional information can be found at the link below

Unit 006 Laying Paving Using Slabs

Five Horizontal Layers Of Soil

Set Out The Dimensions Of The Structure

Stacking Storing Materials & Load Out

Setting Out A Right Angle With Optical Square