Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

The working area needs to be free from any slip or trip hazards, with any furniture being removed from the area.

Protect the floor area with clean dust sheets or you can purchase polythene dust sheets which do not hold dust and will prevent water soaking through to the floor surface.

Do not create a trip hazard with the dust sheets make sure they are flat to the surface of the floor and if needed use masking tape to securely fix the floor or with any overlapping sheeting.

Safety Gloves

Safety Goggles

Safety Face Mask

Chisel Knife

The first step is to clean and degrease the surface completely before you start doing any sanding.

Sanding will remove old paint plus sanding down filler which has been this previously applied.

Paint or Varnish needs to bind to the surface this is why you need to sand down the area before applying any coating materials, this is called “keying” bare wood and plaster should be dry sanded.

Dry sanding produces a lot`s of dust and you need to wear a suitable safety mask.

Surfaces already painted can be prepared in the same way but it is also possible to use Wet Process Sanding.

Old paintwork may contain lead which was used to make the paint dry quicker and harder, old leaded paintwork may be covered by modern painting systems.

If in doubt use the Wet Process Sanding to avoid generating lead dust or you can purchase a commercial lead testing kit.

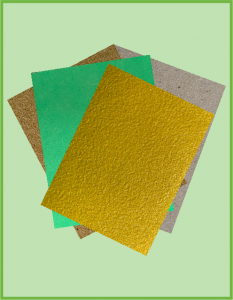

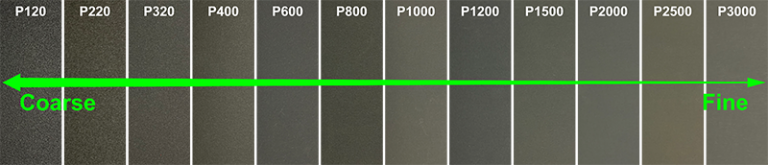

For rough surfaces use “Coarse” paper (60 or 80 Grit).

For general preparation use “Medium” paper (120 Grit).

For sanding between coats use “Fine” paper (180 Grit).

Select a Suitable Grit

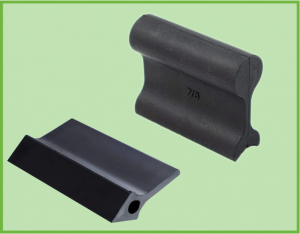

Using Block Sanders

Cut a suitable size of glasspaper paper and wrap it around the block, ensuring That the glasspaper backing is tight on the underside of the sanding block.

Use abrasive paper in sequence of abrasive grit starting with the course and progressing through to the medium and then fine.

Sanding larger areas you can use a hand sander you will need to cut the glasspaper long enough to secure it by the clamps on both ends of the hand sander.

Using Hand Sanders

Sanding Pencil Visual Aid

Pencil visual aid is useful to let you know where you have sanded, lightly scribe lines onto the surface area.

Scribe lines on your high spots to even out the surface area before changing your grit size.

The finer the grit size glasspaper the lighter the pencil marks should be.

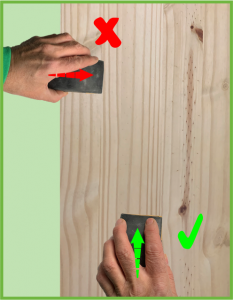

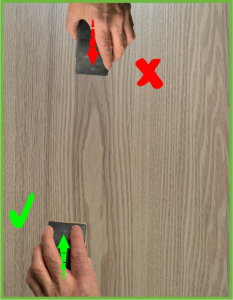

Always sand in the direction of the wood grain with long smooth strokes, without scratching or gouging the surface.

Sanding cross-grain tears the wood fibres so the sanding scratches show up much more, especially when you’re applying clear varnish or wood stain.

direction of the wood grain

direction of the wood grain

Surfaces that have been previously painted sanding should be done on the longest surface run.

You will need to change the glass paper if it becomes blunt all clogged with dust.

Do not apply any lubricants when you are doing Dry Process Sanding.

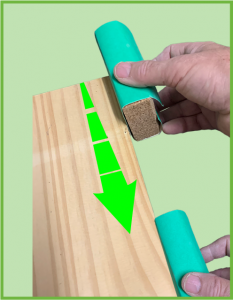

When sanding corners or edges work from the corner to the centre with long smooth strokes, making sure that you use a sanding block and keep it square to the face when sanding.

Sanding from the centre to the corner you are likely to remove the corner profile by rounding off especially if you’re using electrical sanders.

Corners and edges really should be done by hand to prevent excessive sanding down and losing the profile.

Sanding Edges and Corners

Using Wire Wool

Using wire Wool same technique as glass paper you must follow the grain with long smooth strokes, this will soften and enhance the appearance of the surface.

Disadvantages of Wire Wool:

Do not use your bare hands to remove Wire Wool from a bundle, you are likely to cut your hands, use proper tin snips.

Wire Wool will rust if you leave it in damp places.

Dry oak timbers still have sap after the water has been evaporated and this will react to iron in the wire wool creating a blue or black permanent iron stain.

Dry Process Sanding produces a lot of dust during the process, the dust must be removed by vacuum or with a tacking cloth preferably both to ensure there is no dust particles.

When using a dusting brush always dusted away from yourself and where was safety mask.

Do not use a damp cloth to remove the dust as this will cause the wood to swell and you need to let the wood dried before painting.

Cleaning Wood Surface

Tack Cloth

If you’ve used wire wool you need to make sure that you have to remove all wire wool fibres otherwise they will cause rust spots if you use water-based paints.

You can run a magnet over the surface to remove any wire wool fibres or use a lint-free cloth.

Tack cloth is a semi-sticky cloth used for removing fine particles from surfaces before applying any paint systems, especially on wooden surfaces.

s.

Dry oak timbers still have sap after the water has been evaporated and this will react to iron in the wire wool creating a blue or black permanent iron stain.

Wet sanding enables you to have a smooth and higher-finish across the whole surface on painted surfaces which also eliminates dust.

If you suspect there is lead in previous painting systems then you need to use wet process sanding so you don’t inhale the lead particles in the air.

Just like Dry Process Sanding you need to start with a coarse grit working towards the finer grit size, jumping through grit sizes 200 to 300 between sanding pass dependent on the finish you want.

Wet and Dry Glasspaper

Wet Sanding Grit Size

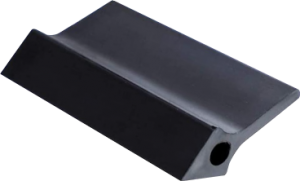

Rubber Sanding Block Step 1

Step 1

Place the wet and dry glasspaper down on a flat surface with the backing paper uppermost, place a sanding block on top of the backing paper and draw a line along the longest edge extending the line at both ends.

If you are using a craft knife, make sure that you do it on a cutting board and cut away from yourself.

Step 2

Lift one rubber flap and insert the glasspaper between rubber flap and the retaining pins.

Ensure that you have lined up the edge of the glasspaper to the edge of the sanding block before pushing down on the rubber flap onto the retaining pin to secure the glasspaper.

Rubber Sanding Block Step 2

Rubber Sanding Block Step 3

Step 3

Place the sanding block flat on a surface, pull gently on the glasspaper and fold over the retaining pins to see if you need to remove any excess glasspaper.

Step 4

keeping the glasspaper taut, place it over the retaining pins and press down firmly on the rubber flap to secure glasspaper.

Rubber Sanding Block Step 4

Rubber Sanding Block Complete

The surface area of the sanding block should have no gaps between the backing paper, otherwise, this will reduce the life of the glasspaper.

Rubber Contour Sanding Grips on very useful for going into difficult areas to sounds like concave and convex profiles which you will find on architraves and skirting boards.

Contour sanding Grips come in various sizes and shapes to match the profile that you wish to sand without blunting surrounding details.

Most contour sanding grips will fit a three-quarter sanding sheets.

Contour Sanding Grips Step 1

Step 1

Place the wet and dry glasspaper down on a flat surface with the backing paper uppermost, place a contour sanding grips on top of the backing paper and draw a line along the side edge extending the line at both ends.

If you are using a craft knife, make sure that you do it on a cutting board and cut away from yourself.

Step 2

Position the glasspaper on one side of the sanding grip profile, making sure that you’ve got enough to hold with your fingertips.

Contour Sanding Grips Step 2

Contour Sanding Grips Step 3

Step 3

Holding the glasspaper on one side of the sanding grip profile, place the glasspaper on the opposite side of the profile if needed cut to length.

Preparing the working area is the same that we mentioned earlier for dry process sanding, ensuring that we don’t have any slip or trip hazards.

Step 1

It is essential that you wash down the working area prior to painting or wallpapering.

You can use sugar soap to remove the grease and dirt and nicotine stains or you can use a less effective method, like warm water with no detergent as the detergent will leave a residue on the surface which will reduce the adhesion of any new coating system.

The surface should be rinsed afterwards using clean water and a sponge.

Preparation Step 1

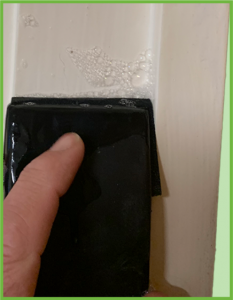

Wet Process Sanding Step 2

Step 2

After preparing your sanding block dip into your container with warm soapy water, this will help the glasspaper to glide over the surface.

Start from the highest point rubbing down the overlapping circular motion working in small areas at a time approximately 300mm.

Before moving on to the next area wipe down the area with a clean cloth and allow to dry.

Step 3

On a flat narrow surface like door liners and skirting boards use a rubber sanding block or cork block and sanding the longest direction

Wet Process Sanding Step 3

Wet Process Sanding Step 4

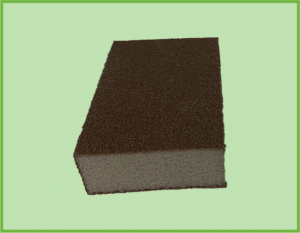

Step 4

On curved surfaces like architraves and mouldings best to use a Sandpaper Sponge which will take up the profile without damaging the surrounding areas.

Step 5

The wet and dry glasspaper will need to be rinsed frequently to stop the paper from clogging up, also check your container that the water still warm and have still got soap suds.

Wet Process Sanding Step 5

Wet Process Sanding Step 6

Step 6

Once you are happy that you have sanded all the surfaces run your fingers over the surface carefully to check to see if his any lumps or bumps, your fingers are more sensitive than your hand.

The surface area will need to be rinsed down with clean water to ensure that there is no residue on the surface which will reduce the adhesion of any new coating system and allow to dry.

Not all surfaces are flat and normal sanding blocks are unable to reach these areas like grooves in mouldings and concave areas.

Contour Sanding Grips are designed specifically for these types of areas and are made out of flexible but stiff rubber.

Contour Sanding Grip