Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

There is plenty of commercial sanding equipment out there unless you are professional painter and decorator you are not going to have all the specialised tools and equipment, so we have put together some alternative solutions for sanding in awkward places.

The selection of Tools and Equipment are examples of what you could use.

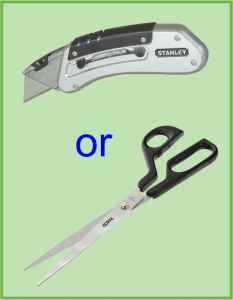

Trimming Knife or Scissors

Wire Wool

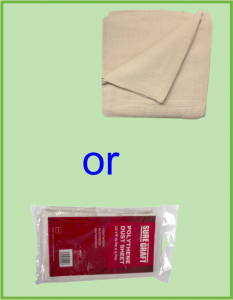

Tack Cloth or Lint Free Cloth

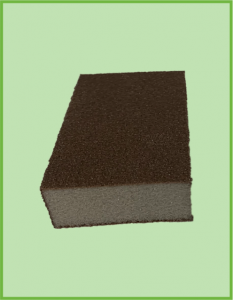

Sanding Sponge

Sanding Sponge

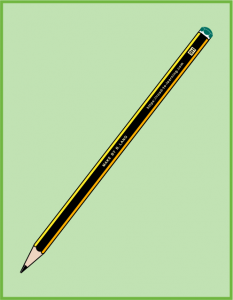

Pencil

Portable Hoover

Natural Jute Twine

Glasspaper and Duct Tape

Dusting Brush

Dust Sheets

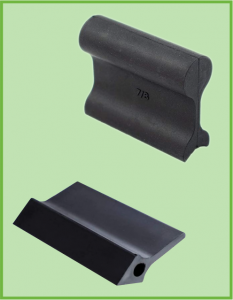

Contour Sanding Grips

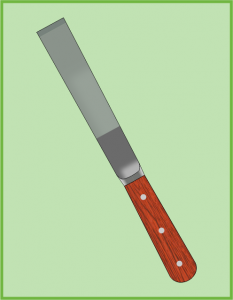

Chisel Knife

Lollipop Stick or Scrap Timber

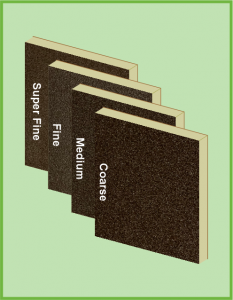

Selection of Sanding Pads

Plastic Container

Health and safety is an important part of any work activity make sure that you have the right P.P.E. for the work activity.

Always read the manufacturers instructions before using any tools or materials, if you’re still unsure do some research on the Internet.

Don’t forget to prepare the working area with dust sheets and remove any furniture or ornaments before starting.

Safety Goggles

Safety Gloves

Safety Face Mask

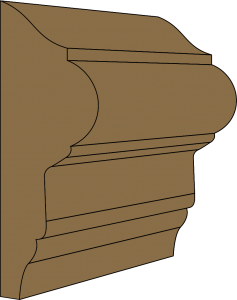

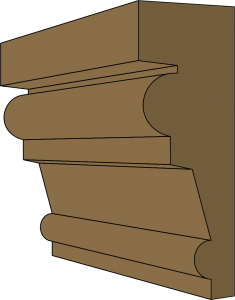

When we are preparing room for decorating not all surfaces are flat and easy to reach with an orbital sander or handheld block sander, and sometimes even a details sander can’t reach.

Hard to reach places like louvred doors, vents or Crown Mouldings for ceilings, other

examples of Decorative Moulding are:

Dado Rail

Architrave

Cover Moulding

Dado Rail

Furniture Moulding

Hand and Base Rail

Panel Moulding on Doors

Picture Rail

Skirting Board

Architrave

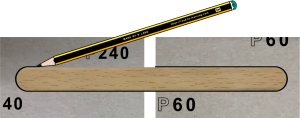

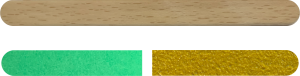

Custom-built Flat timber sanding file ideal for areas where a traditional details sander cannot reach because of its size.

The length and the width of the timber sanding file will depend upon the area which needs sanding.

fig 1

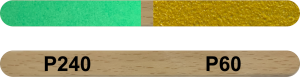

In this example, I have used a lollipop stick, in fig 1 you will see that the two different grit size, and drawn a line around the stick.

In fig 2 both outlines have been cut out using scissors and are ready to be stuck on to stick using quick-drying spray adhesive.

fig 2

fig 3

fig 3 shows the glasspaper fixed to the stick and your notice on the opposite side of the stick we have marked the grit size for future reference.

Sanding curves (concave) you need to do this by hand otherwise you could quite easily damage the Decorative Moulding using mechanical sanders.

There are different mediums you can use commercially sanding materials or improvise using existing glasspaper and duct tape, here are a few examples.

Sanding Sponge

Using a rounded sanding sponge to fit inside a curve making sure you keep the same angle as you’re running the sponge up and down the profile.

Apply enough pressure to sand the area, excess pressure will damage the moulding profile.

A big advantage of using sanding sponge on completion of the job, you can remove most of the dust from the surface of the sponge then wash out the remaining dust in a warm bowl of water with detergent and allow to dry

If you haven’t got round sanding sponge you can use a sanding pad or square edged sanding sponge rolled up to form the shape of the curve to be sanded, ideal for different sizes of concave curves.

Principles of a sanding pad remain the same as before, the only difference is that you must maintain the shape using your fingers at all times.

On completion of a job cleaning sanding pad the same way as the rounded sanding sponge.

Sanding Pad

When sanding curves of Glasspaper the paper needs to be stiff enough to maintain the shape of the curve you wish to sand.

One method is to reinforce a glasspaper with duct tape, or if you have an old belt sander paper this can be cut to the required dimensions as it has a cloth backing which is more rigid than normal backing.

If you find that the glasspaper is not maintained in the shape of the curve and you need additional support inside the core you can use some old glasspaper rolled up and taped together for additional support.

Rubber Contour Sanding Grips on very useful for going into difficult areas like concave and convex profiles which you will find on architraves and skirting boards.

Contour sanding Grips come in various sizes and shapes to match the profile that you wish to sand without blunting surrounding details.

Most contour sanding grips will fit a three-quarter sanding sheets.

Larger curves you can use a piece of timber dowel or even an old broom handle that fits inside the Curved Mouldings and wrap it with glasspaper.

Alternatively, a rubber hose or even a cartridge tube from a skeleton gun can be used, just think outside the box.

Recesses in mouldings can be sanded using a small folded piece of Glasspaper, which can be pushed up and down along the groove.

Alternatively, for extra control, fold the paper over the end of a scraper.

Use a Sanding Sponge for wider grooves, ensuring that you do not apply too much pressure which will deform profile shape.

Acute Angle Contour Grip is also useful which is a lot stiffer than the sanding sponge which will retain its shape and give you extra control.

Depending on the sizes of the groove will influence the medium used, whichever medium you use to make sure that you do not destroy the profile shape.

Sanding around plumbing pipes can be challenging at best of times because plumbing pipes are clipped to the wall leaving not much room between the back of the pipe on the wall.

Ideally, before you start sanding use the side of a decorator’s Chisel knife and run it up and down the pipe on all sides, this will remove any loose paint or nibs of paint otherwise, this tends to rip your glasspaper or a sanding pad.

If you haven’t got a chisel knife you must use a knife blade which is strong enough to take the punishment of removing paint nibs.

Paint nibs is paint which has picked up dust or particles when applying paint systems and applying too much paint in one go causing the excess paint to form a visible drip.

Whichever medium you need to make sure that the abrasive is in contact completely around the pipe before you start sanding up and down in a twisting circular motion.

Using a damp cloth or Tack cloth to remove any dust from the surface using the same method as if you were sanding, and allow to dry before applying any paint systems.

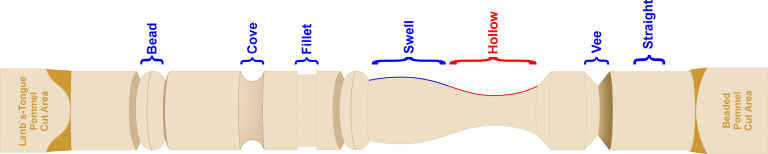

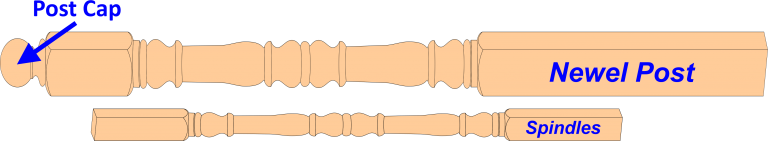

No matter how complex it might look, every turned spindle consists of basic shapes, shown in the above diagram, used alone or in various combinations.

Different methods of sanding are needed for the different shapes with some materials being better suited than others we should take a look at a few examples below.

A pommel cut on a spindle is the transition between a straight-sided pommel (usually square) to the round or turned portion of the piece

Sanding spindles by mechanical means is not recommended as you can quite easily destroy the intricate shapes on a spindle.

Use commercial sanding sponges or pads, alternatively cut strips of glasspaper to suit the area that your sanding ideally reinforced glasspaper with duct tape before cutting.

Unfortunately sanding spindles is a labour-intensive exercise and most people dread the thought but you must be methodical breaking down the working areas of spindles.

When sanding down any areas work from the bottom area to the top, any sawdust or flakes of paint will drop onto previously prepared areas and can be removed with a dusting brush later.

Beaded or Lanb`s-Tongue Pommel Cut Areas are not all the same shape you need to adapt your glasspaper or sanding sponge to the Pommel Profile, this can be done by folding the glasspaper or sanding sponge to sand down the Pommel area.

The grit size would need to be increased because of the end grain normally in this area.

Sanded inside Vee or Fillet Area can be difficult at times, there are several ways you can use, depending on the size of the opening you could use folded pieces of glass paper and working around the spindle or newel post.

An alternative method is to use strands of wire wool twisted into a rope to the required thickness and placing it around the area and crossing over the wire wool then moving the wire wool backwards and forwards.

Sanding with Wire Wool

Sanding with Wire Wool

If you haven’t got wire wool you can use natural garden Jute Twine which is just rough enough for a light sanding adopting the same method as above.

Caution if you are staining or varnishing wooden spindles or newel post be careful not to scorch the timber by excessive rubbing.

The easiest part of the spindle or newel poster sand is the swell and hollow area, simply have enough glasspaper or sanding pad to wrap around the circumference of the widest area with an overlap.

Using the twisting motion from left to right and sanding up and down simultaneously to get an even sanded surface.

Sanding with Pad

Small bead areas can be difficult to sand, you can use reinforced glasspaper cut into thin strips just like the method when using wire wool or garden natural Jute Twine.

The alternative method is to wear safety gloves and get a bundle of wire wool in the palm of your hand enough so it mould itself around the bead area, then applied pressure in a twisting motion from left to right to sand the area.

You need to ensure that you remove all the wire wool fibres from timber otherwise likely to rust when applying water base painting systems.

Dry oak timbers still have sap after the water has been evaporated and this will react to iron in the wire wool creating a blue or black permanent iron stain.

Sanding Bead Area

During the sanding process, you will create dust when dry sanding you need to remove all the dust from the surface in preparation for the paint system you wish to apply.

Using a dusting brush start from the top working area working down to the base area, remembering to brush away from yourself and wear the appropriate P.P.E.

Ideally use a vacuum cleaner with a thin hoover nozzle to remove most of the dust from vee or fillet area.

Do not use a damp cloth to remove the dust as this will cause the wood to swell and you need to let the wood dried before painting.

Use a Lint-Free Cloth and white spirit or Tack Cloth to remove the remaining dust before applying any paint systems.

Cleaning Wood Surface