Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Brick Delivery Truck

Bricks can be delivered to site in two ways.

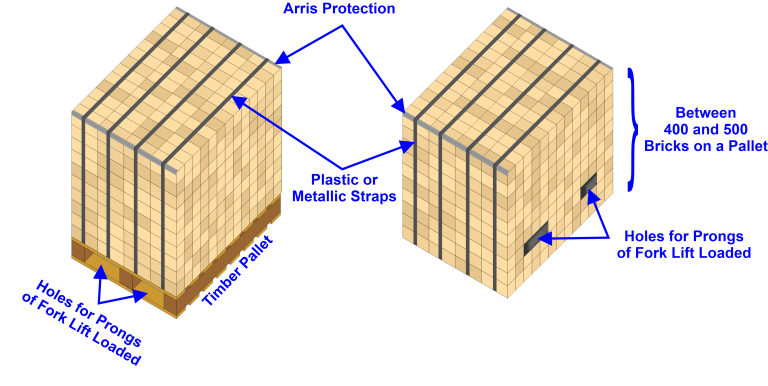

One is bricked are stacked on wooden pallets and bound with metal or plastic straps alternatively a pack of bricks will have its recesses for of forklift please packs are generally covered with shrink-wrapping.

Bricks are Stacked on Wooden Pallets

These are unloaded and placed by crane or fork-lift.

The second way, generally for small quantities, is for the bricks to be stacked onto the lorry and off-loaded and stacked by hand.

Stacks should NOT be greater than 3 brick pallets high and unloaded by a competent forklift driver.

Telehandler

Some ground rules for stacking pallets

· Check the condition of the wooden pallets before lifting by mechanical means

· The Straps need to be checked before lifting, the packs are bounded with metal or plastic banding to provide support.

· Pallets should be stacked on firm level ground and firm enough to take the load.

· Specials or abnormal materials should be stacked individually on the ground.

· Forklift driver to avoid sliding the packs against each other when stacking, this would damage the face of the brick also could split the pack open.

· Stacking pallets should have a gap around the stack to prevent knocking or sliding pallets against each other.

· Only lift packs of bricks or blocks by purpose-made holes in the stack or by 2 sometimes 4 opening ends of the wooden pallet.

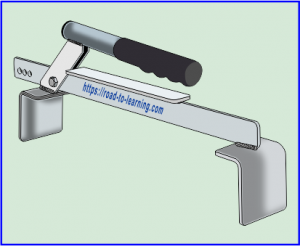

Brick Lifting Tong

Hod Carrier

Wheelbarrow

Tin Snips

Cold Chisel

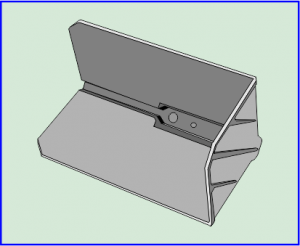

Wooden Pallet

Wearing the Correct P.P.E.

Personal Protection Equipment (P.P.E.) is needed before any blending of any bricks, plus tools and equipment to safely carry out this activity.

You will need a wooden pallet to stack the bricks onto, plus a Cold Chisel and Tin Snips to cut the banding around the bricks.

The bricks normally banded with metal or plastic banding under tension to provide support.

Care should be taken when cutting banding straps since it can spring up and cause damage or injury.

The straps are under tension you would need a cold chisel to lift straps away from the face of the brick enabling you to usual tin snips to cut the strap.

Brick strapping should be made safe immediately, this might mean that you cut the strap again at the base of the stack so doesn’t create a trip hazard and bundle the loose straps and remove it from the working area.

Do not use a Lump Hammer and Cold Chisel to break the straps, this will damage the face of the bricks and the edges (Arris)

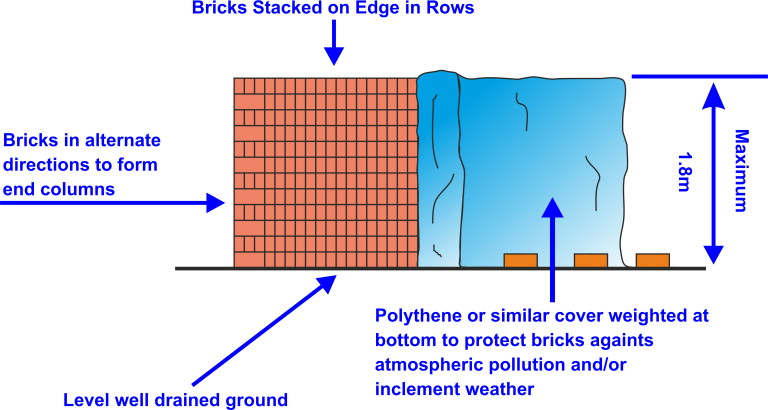

Bricks Stacked

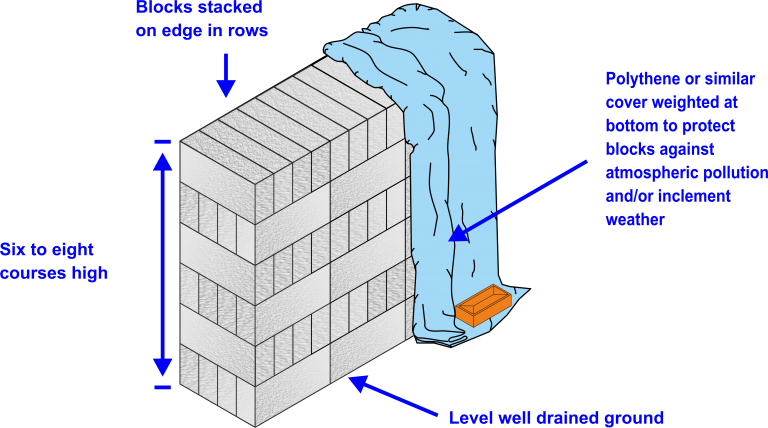

Blocks are usually delivered on pallets as described for bricks.

They can also be off-loaded and stacked by hand where small quantities are involved.

Blocks are stacked on pallets or on level ground.

Their shape and size enable them to be cross-bonded in pairs or more and there is no need to slope the ends as with bricks.

Although bricks and blocks are made for use externally when in the stack they can be affected by the weather, e.g. frozen water, algae, discolouring by dead leaves, unless suitably protected.

Blocks Stacked