Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

Cavity wall insulation forms a barrier to stop the heat from escaping from the inner wall of the building.

There are a variety of schemes and options available to assist with funding for energy efficiency home improvements such as Cavity Wall Insulation and Loft Insulation.

The requirement to improve energy efficiency and reduce carbon emissions in new buildings has led to the introduction of increasing levels of insulation.

Cavity walls provide a convenient and efficient way to control heat transfer, and the opportunity to locate insulation materials in a major element of a structure.

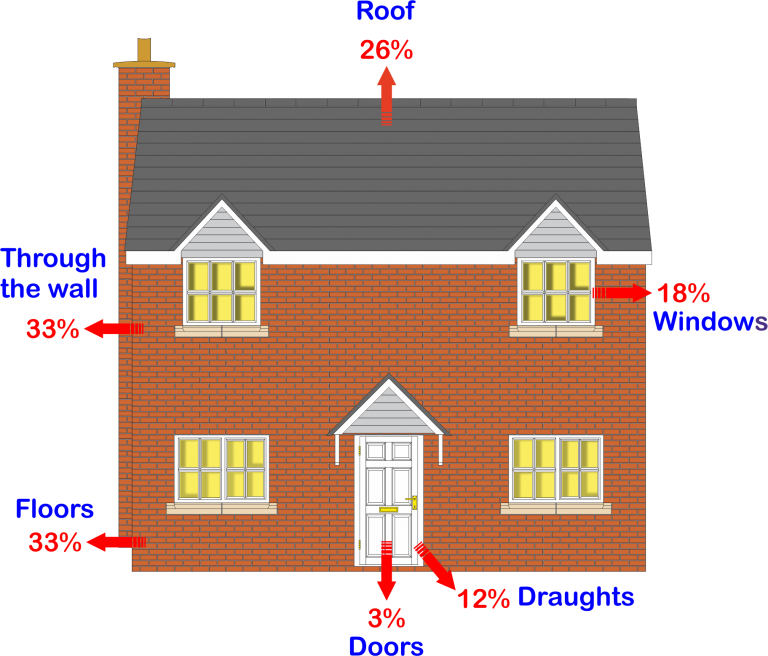

Insulation loss

The national insulation association estimates that 33% of a property’s heat is lost through the walls.

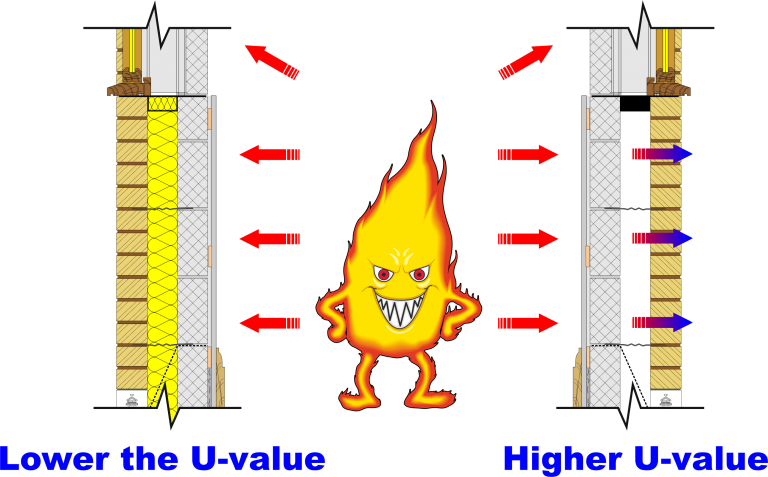

Cavity walls are designed to prevent rainwater from reaching the internal leaf of a cavity, if a cavity has no insulation than Higher the U-value and the heat generated inside the house will escape through the cavity.

In most cases during construction bricklayers place insulation slabs in the cavity space during construction.

Lower the U-value as heat is transferred through the cavity saving money and the environment.

There are several types of insulation that can be used some are more efficient than others, you will need to read the manufacturer’s datasheet on thermal values.

Thermal Values

Insulation can also be ranked using a U-value which calculates a materials insulating effectiveness in watts.

When choosing insulation for your cavity use material that has a U-value close to 0 as possible as this is the most efficient insulation.

An R-Value rating is given to insulation to measure its thermal resistance with the standard measurement given in square metre kelvin per watt.

It measures the temperature variation over insulation and also the amount of heat transferred through the insulating material.

The higher the calculated number value the more effective the insulating material will be at preventing heat transfer.

The R-values primary measure is the insulation materials ability to prevent or reduce heat flow.

Thermal Values

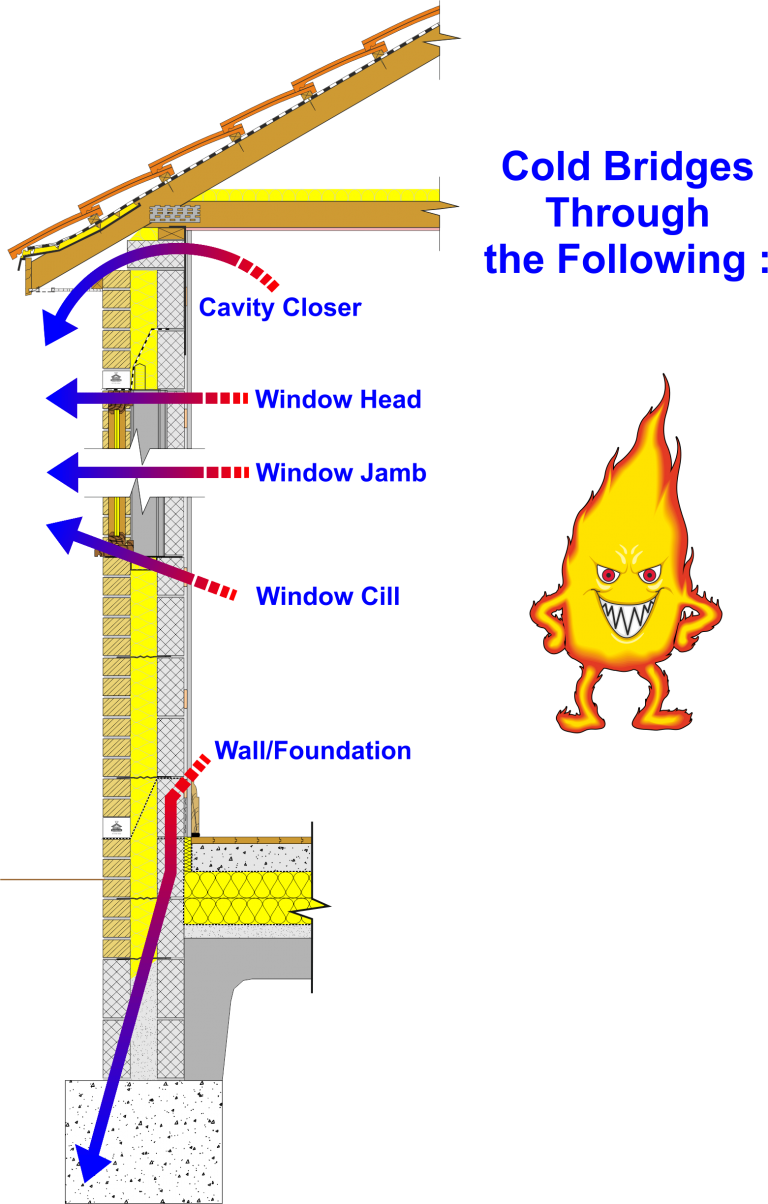

Thermal bridging occurs when there is a break or penetration in the installation especially at junctions in walls and floors, other areas like around windows and doors if not properly insulated then thermal bridging will occur.

To avoid thermal bridging bricklayers must work to a high standard keeping their cavities clean from mortar droppings and follow the manufacturer’s installation instructions.

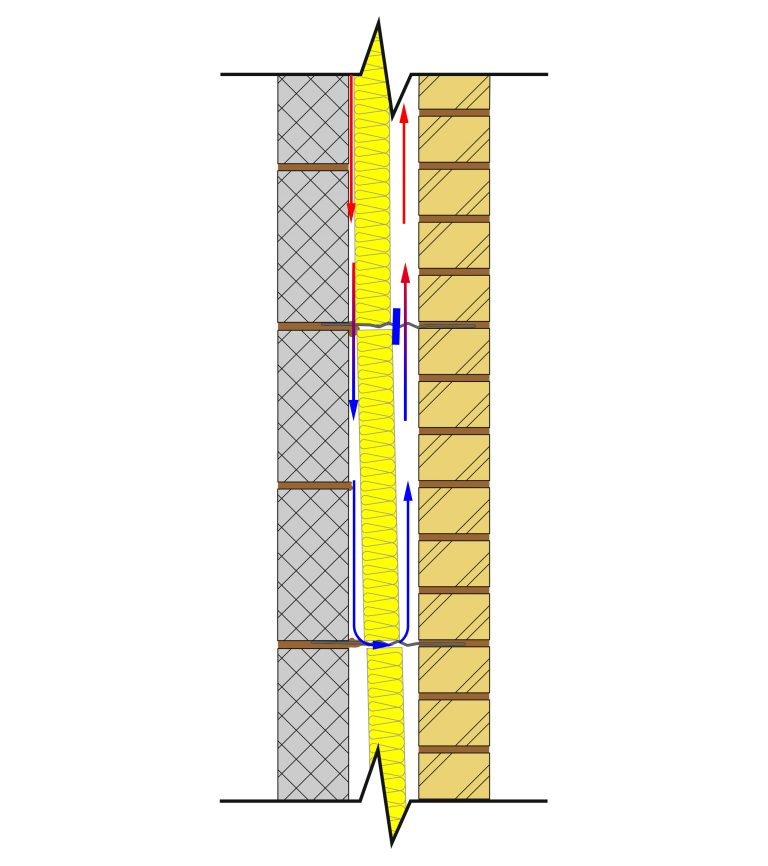

Thermal looping happens when there is air between the flexible slabs or ‘Batts’ this allows the air to circulate around the insulation drawing heat from the inner leaf of the wall.

Gaps can be prevented by ensuring that the insulation is fitted correctly and Surplus mortar in the bed and perp joints are removed carefully without creating mortar droppings onto the flexible slabs or ‘Batts’.

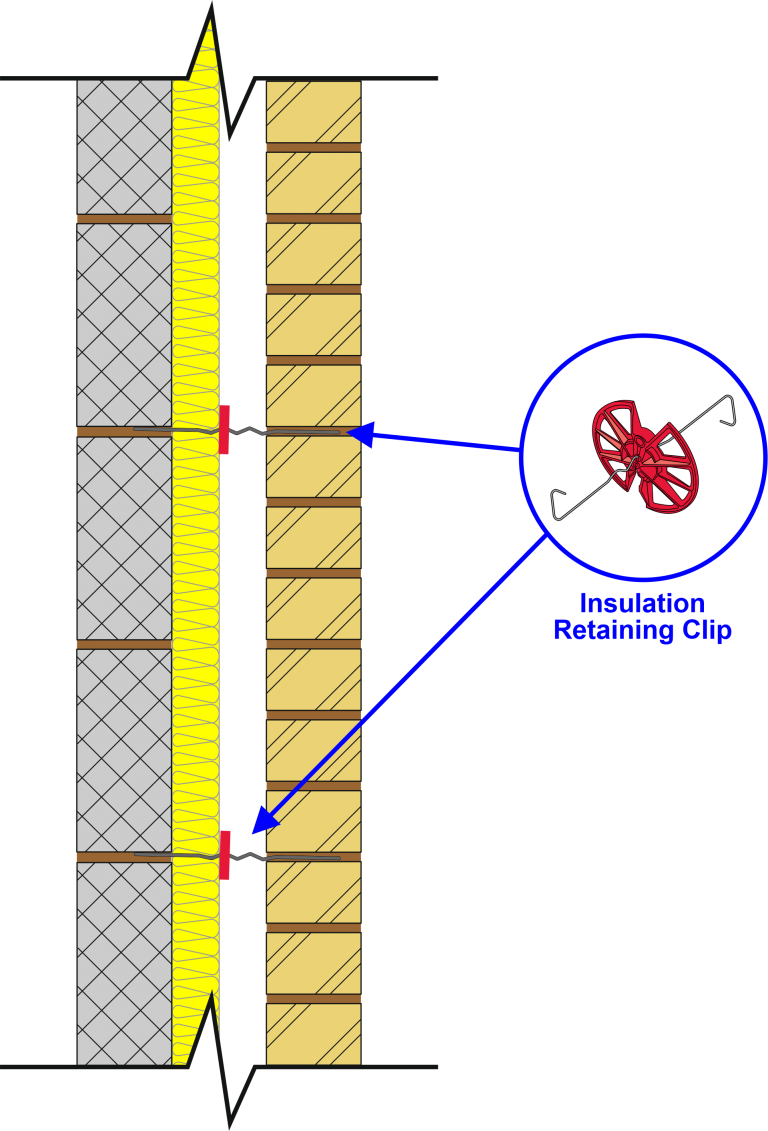

When cavities walls are Partial Fill with flexible slabs or ‘Batts’ the wall ties must include retaining clips/discs to ensure insulation is held back in the correct position eliminating air pockets.

Thermal Looping

Not following the manufacturer’s instructions and poor workmanship will affect the U-value of the insulated cavity.

Thermal Looping’s affect on the U-value:

Gap = 0mm U-value = 0.34

Gap = 3mm U-value reduced to 0.54 = 159% decrease in performance

Gap = 10mm U-value reduced to 0.65 = 193% decrease in performance

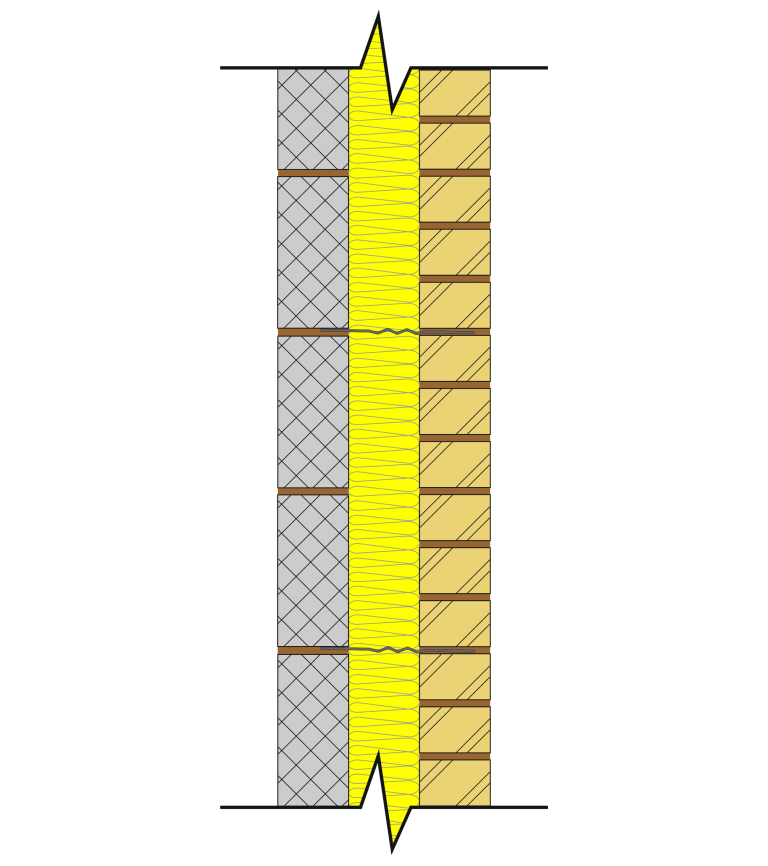

Insulation - Full Fill

Sometimes called total fill.

As the name suggests, this method fully fills the cavity with insulation material so that no air gaps remain.

The material used is usually manufactured in the form of flexible slabs or ‘batts’.

This form of insulation can also be effective in preventing the spread of fire.

This method allows an air gap of a minimum of 50mm to be maintained.

The insulation material is in the form of rigid sheets of material and is fixed to the inner skin or leaf by special clips attached to the wall ties.

Insulation - Partial Fill

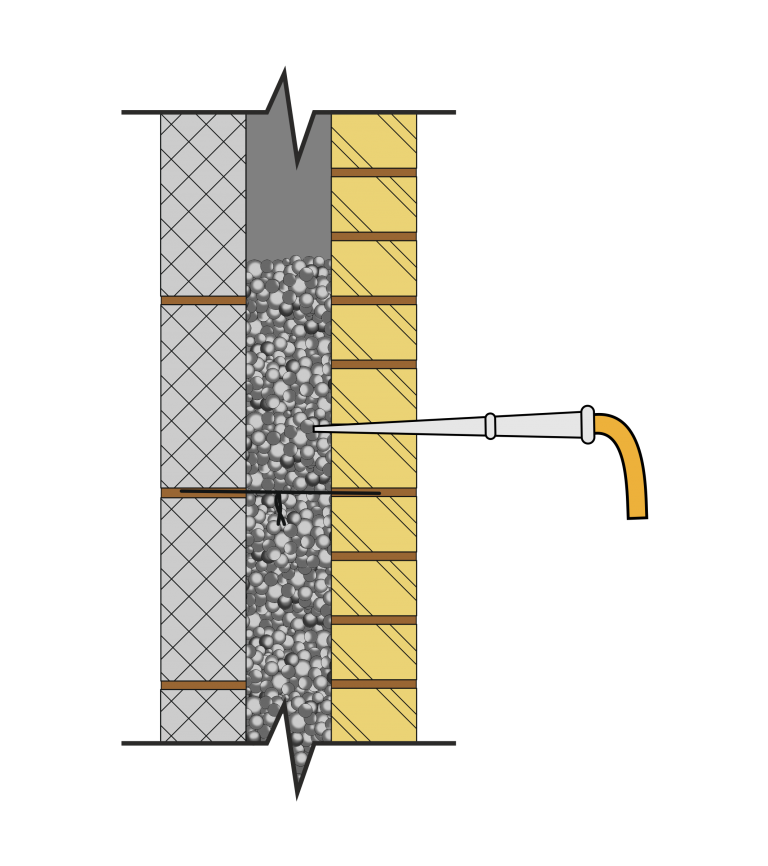

E.P.S. Beads

EPS Beads are made out of expanded polythene beads that do not absorb water which reduces the chances of transferring water from the outside leaf into the inner leaf.

An adhesive is mixed with EPS beads during the installation process when dry forms a single mass of insulation inside the cavity.

Beads are supplied in white or grey beads, the grey beads have slightly better thermal properties.

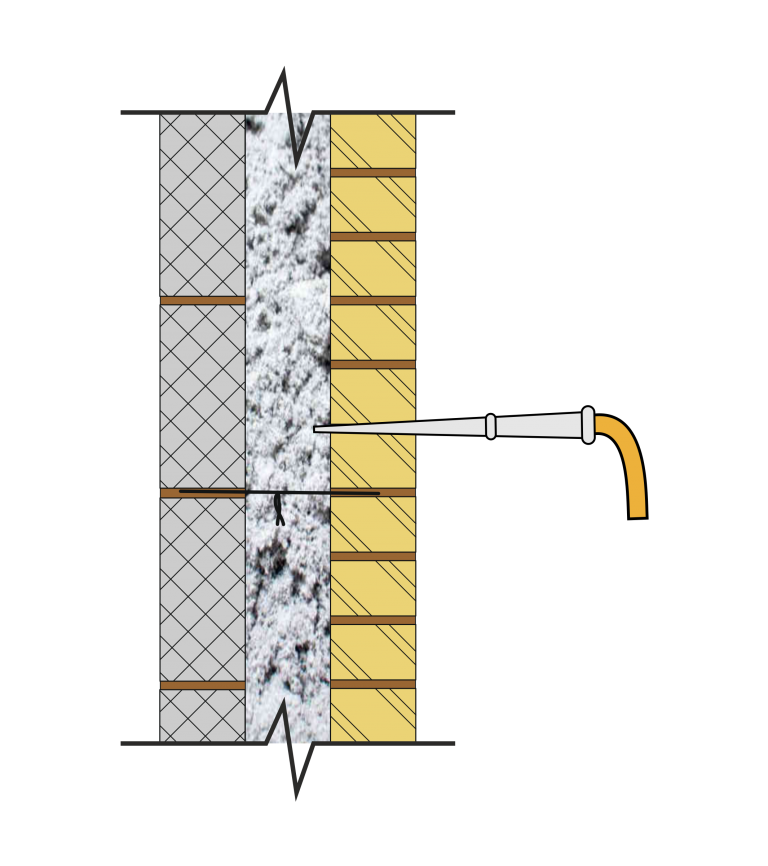

Polyurethane Foam cavity insulation is a two-part solution that gets injected into the cavity under pressure, Polyurethane Foam is suitable for new and old buildings especially hard to reach areas inside the cavity.

This type of insulation has a lower the U-value down fibreglass insulation, and it also helps to bond the inner and outer leaves together providing additional stability to the building

Polyurethane Foam

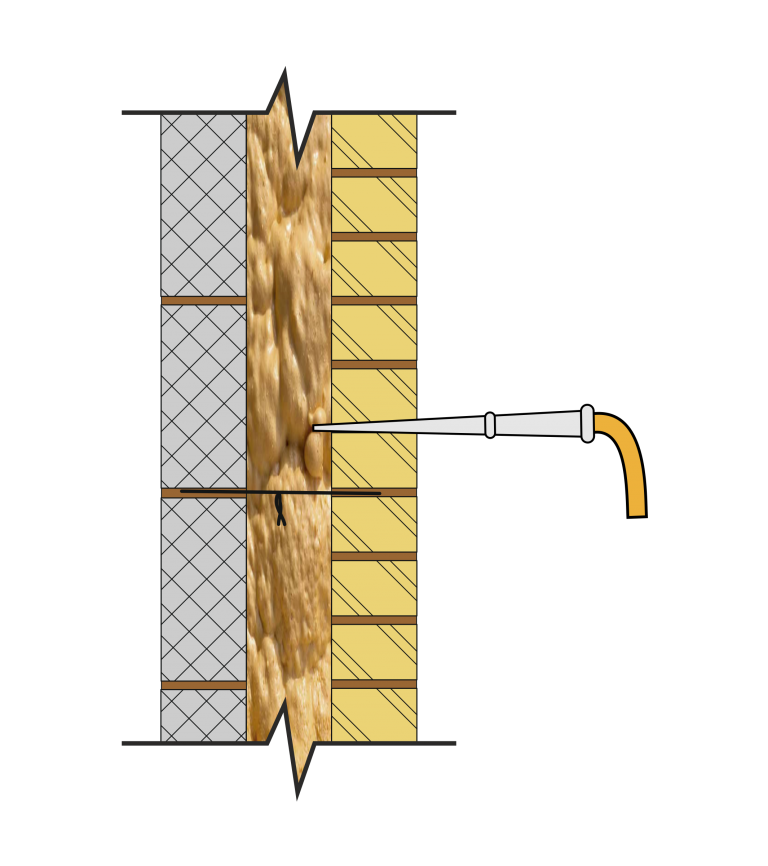

Blown Mineral Wool

Blown-in Mineral Wool is made up of the same material that you see in your loft, the colour can be white or a yellowish-brown.

It has several applications like cavity walls, loft space and ceiling voids common, made of rock, furnace slag, and other raw materials which is all combined with a water repellent.

Issues with mineral wool insulation if not done correctly will cause dry and wet slump’s, and cold spots which could lead to dampness and mould.