Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

5. know how to form openings in cavity walling.

The learner can:

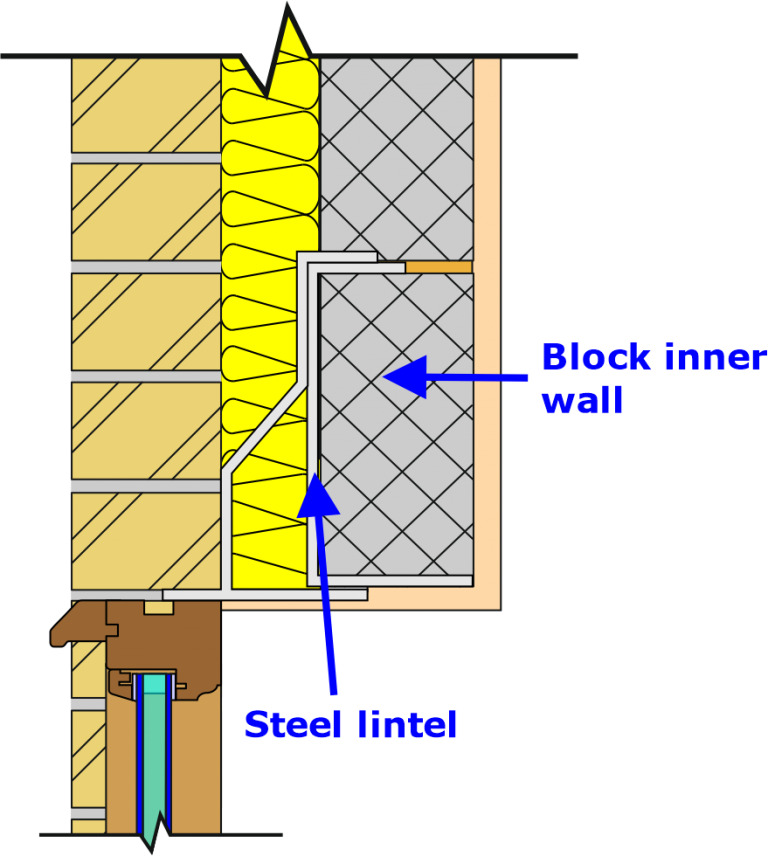

When forming openings in cavity walling, a means of supporting the masonry built above the opening must be provided.

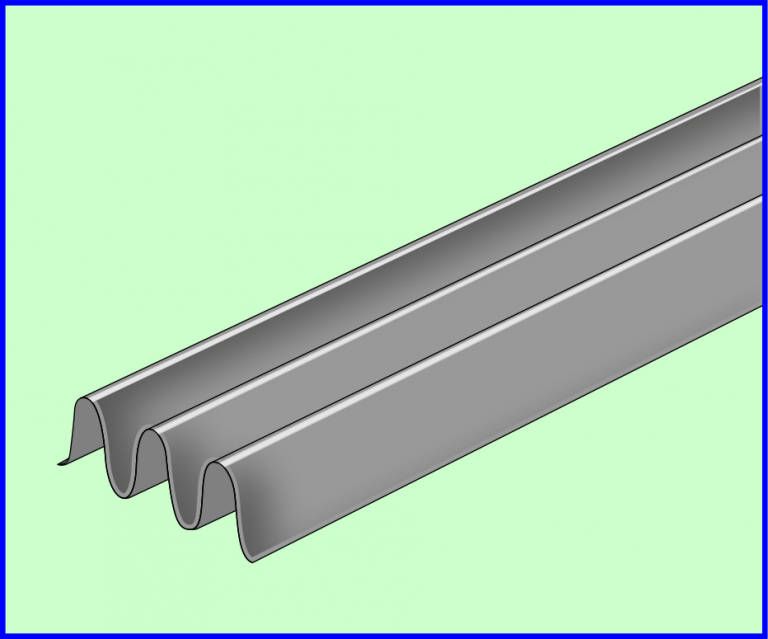

Steel or concrete lintels are used for this purpose and are manufactured in a large range of designs and dimensions.

Bridging Openings

Openings in brickwork can be formed as work progresses or they can be formed when an opening such as a window or door is required at a later date in a wall that has been constructed previously.

When openings are required in brick walls, the brickwork above the opening will be require some form of support.

Even though the brickwork may be bonded correctly, the area immediately above the opening will more than likely collapse because of the loadings imposed from above.

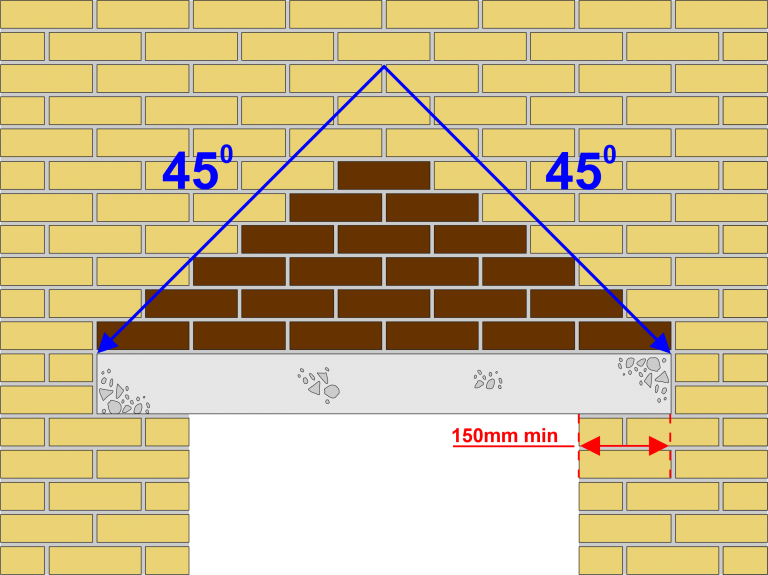

If we consider an opening of any given size, the area that is likely to collapse is roughly in the shape of a 45˚ triangle directly above the opening.

However, if the opening is inserted at a later date, the area that may collapse can be encompassed within a 60˚ triangle directly above the opening.

Bridging Openings

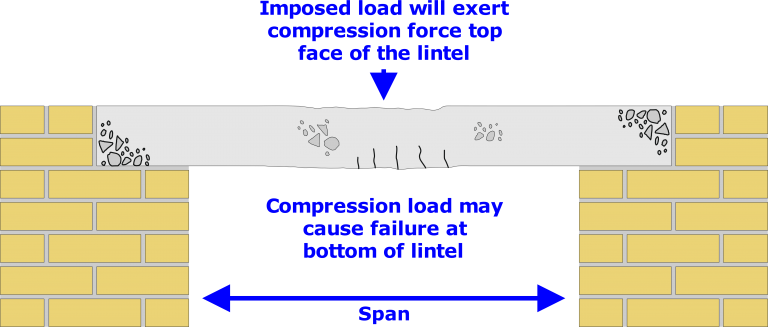

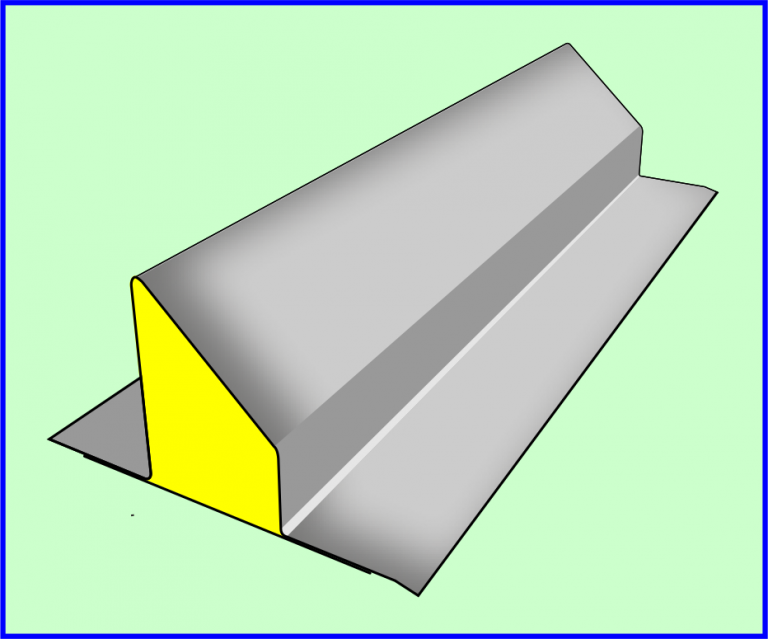

When loads are imposed upon a lintel, the lintel will have a tendency to sag or bend at its weakest point.

Because the lower part of the lintel is being stretched it will be in ‘tension’ while the top part is being squeezed, and will be in ‘compression’.

In addition the lintel will be subjected at the points of support (the side walls) where the vertical loads are trying to sever the beam.

The imposed loads create stresses upon or within any lintel, in particular at the top and at the bottom, which may cause cracking and failure.

The size, shape and design of a lintel must be such that it can overcome these imposed stresses and loads.

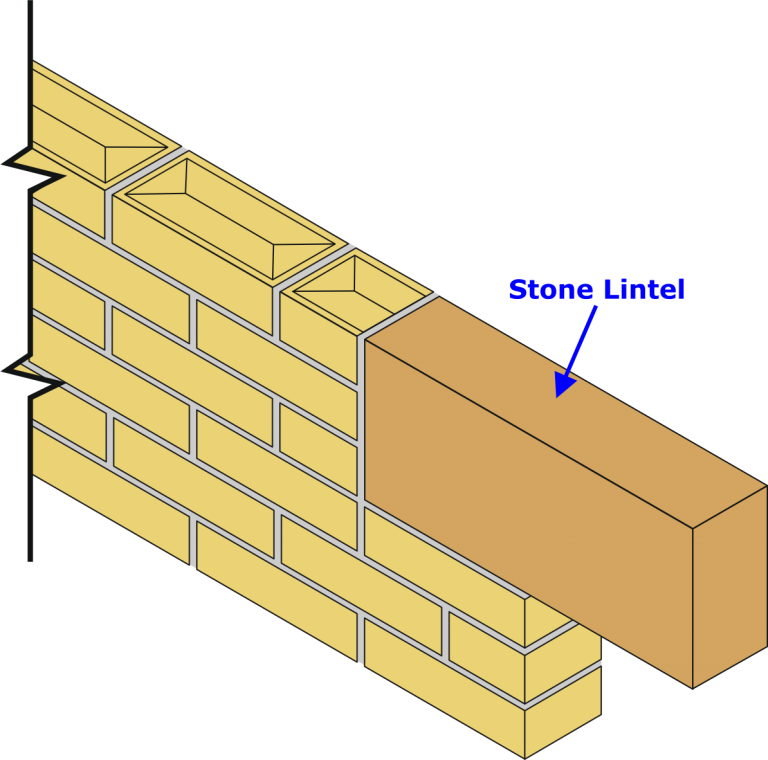

Stone Lintel

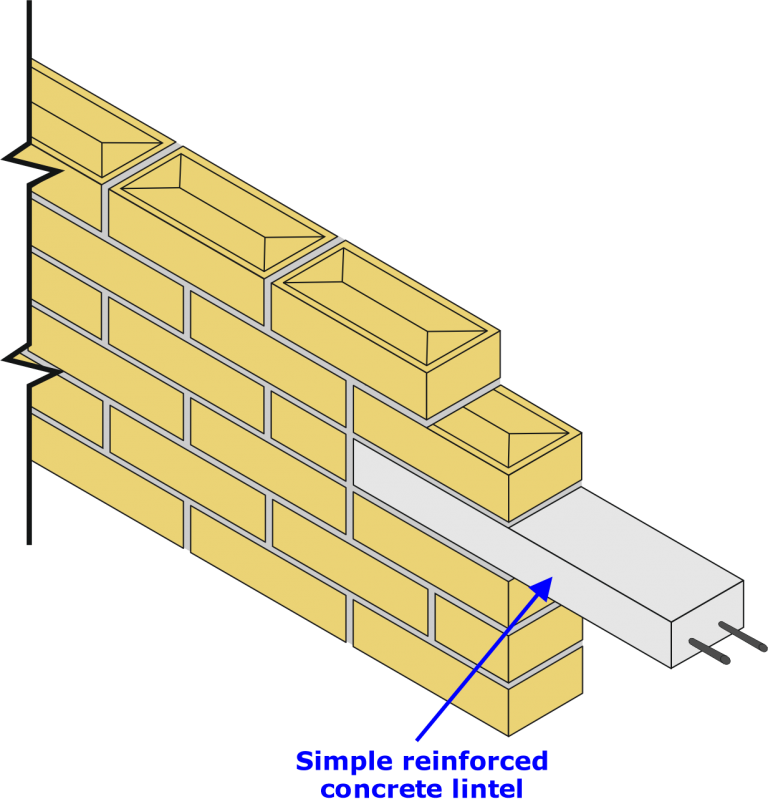

Reinforced Concrete Lintel

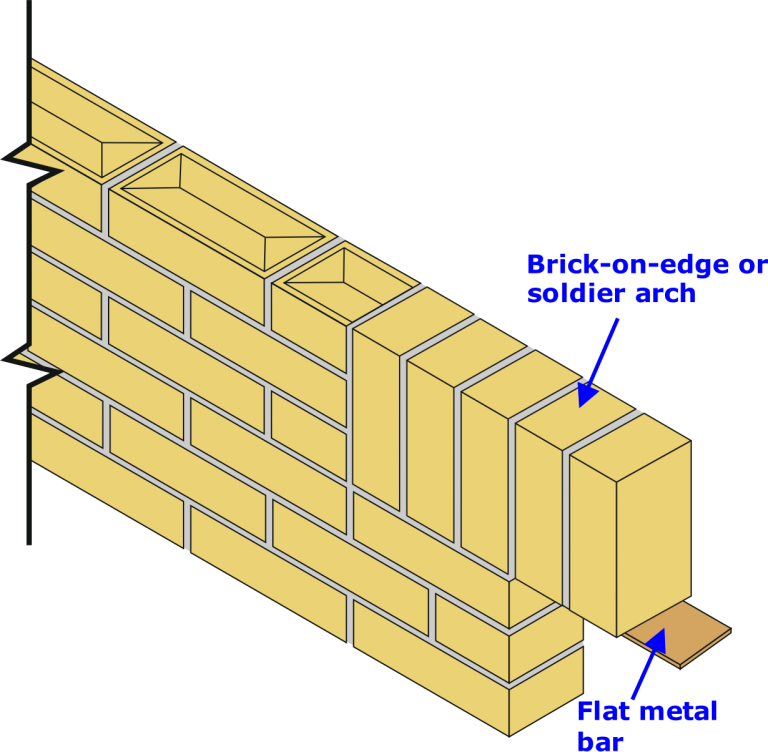

Flat Metal Bar Lintel

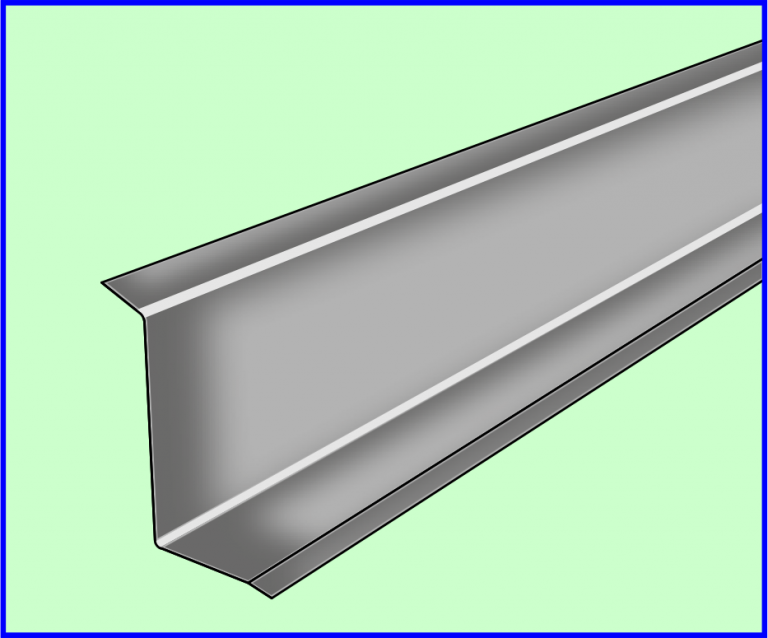

Steel Lintel

The constructional member inserted into a wall to support a load above an opening is called a lintel.

A lintel may be a horizontal timber, steel, concrete or stone beam which spans over openings in walls and supports the structure above it.

In early buildings a large timber beam or a large block of stone would be used to support any imposed loads.

Modern lintels are made from either reinforced concrete or galvanised steel or a combination of both.

Insulation is inserted into the void of the lintel to optimise the thermal performance extending continuously along the full length of the lintel and cannot be dislodged, leaving no potential ‘cold spots’.

These types of lintel are extremely strong and can support masonry over considerable spans, enabling large windows or door openings to be installed without additional support.

The design of the lintel will determine the method of construction required at lintel level.

Whichever type of lintel is used, it is the bricklayer’s responsibility to make sure that the lintel is properly installed and that the bearing is as per the specification (a minimum of 150mm).

Timber Frame Lintel

Special Steel Lintel

Internal Lintel

Insulated Lintel

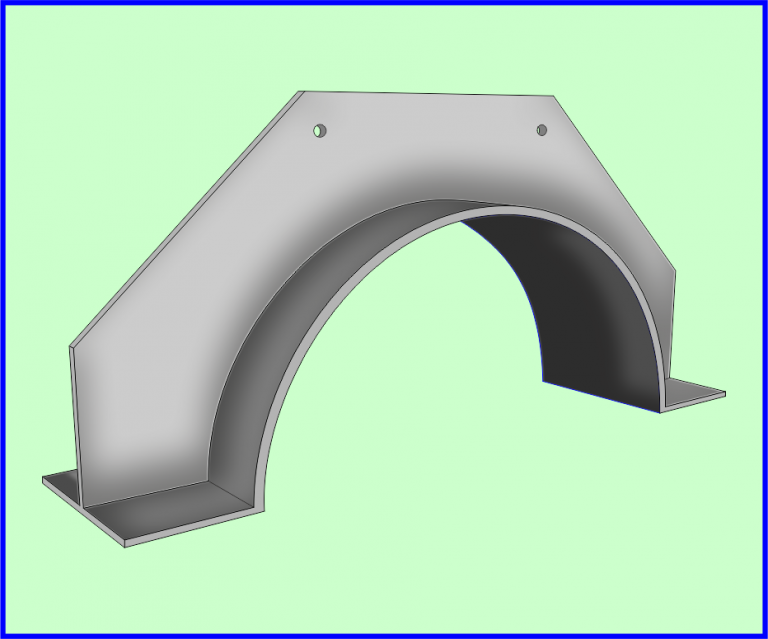

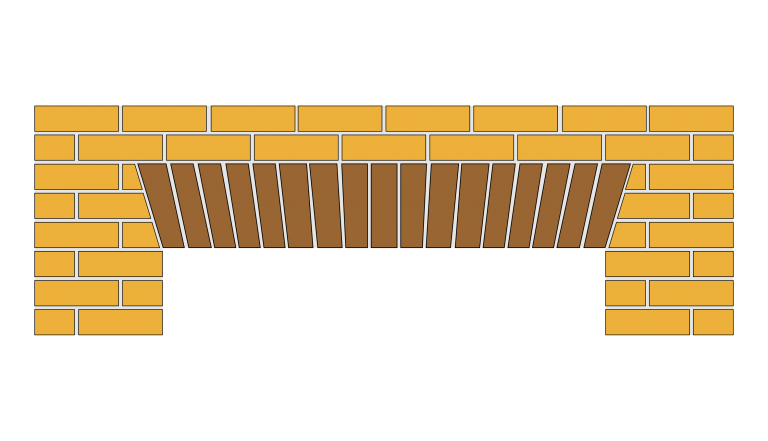

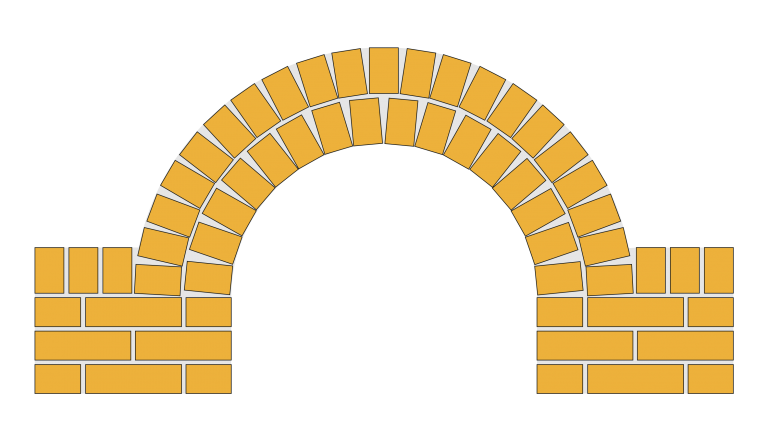

Although the modern method is to span openings by using lintels manufactured from steel there are still occasions when arches are specified in modern buildings to add character to the design.

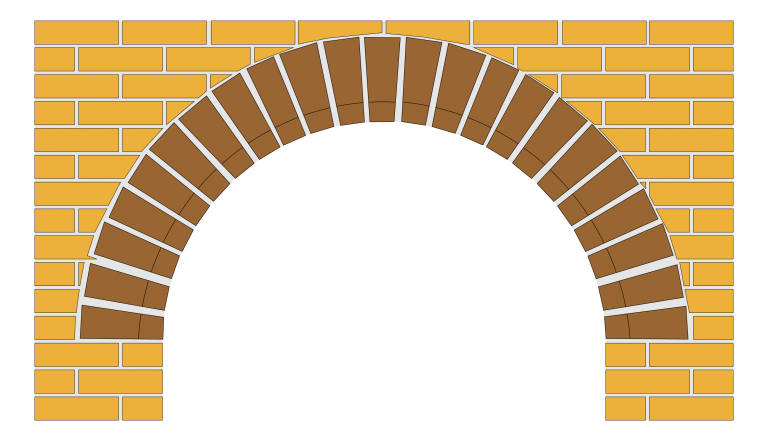

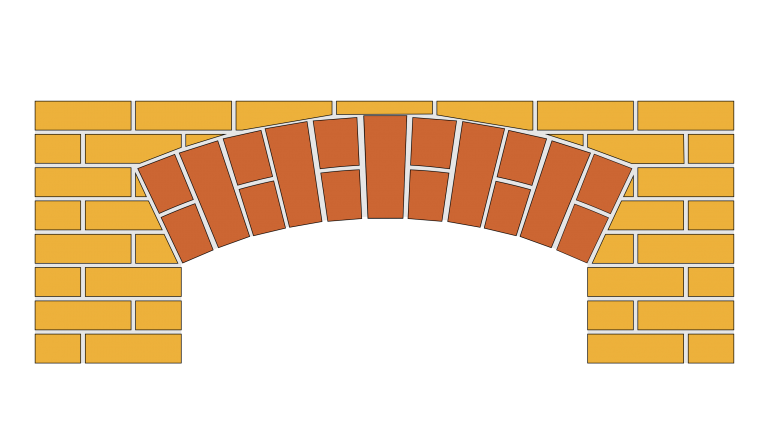

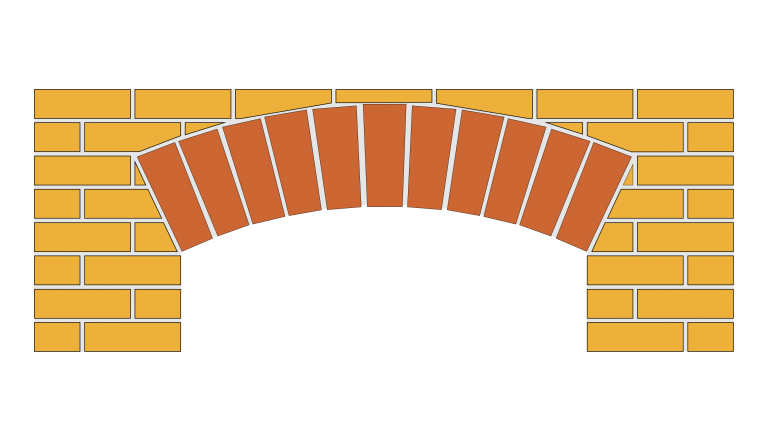

Arches can be designed in many shapes, but the most commonly used types are semi-circular and segmental arches.

If we were to draw a complete circle, a semi-circular arch would be formed by half of the circle and a segmental arch would be formed by a segment of the circle.

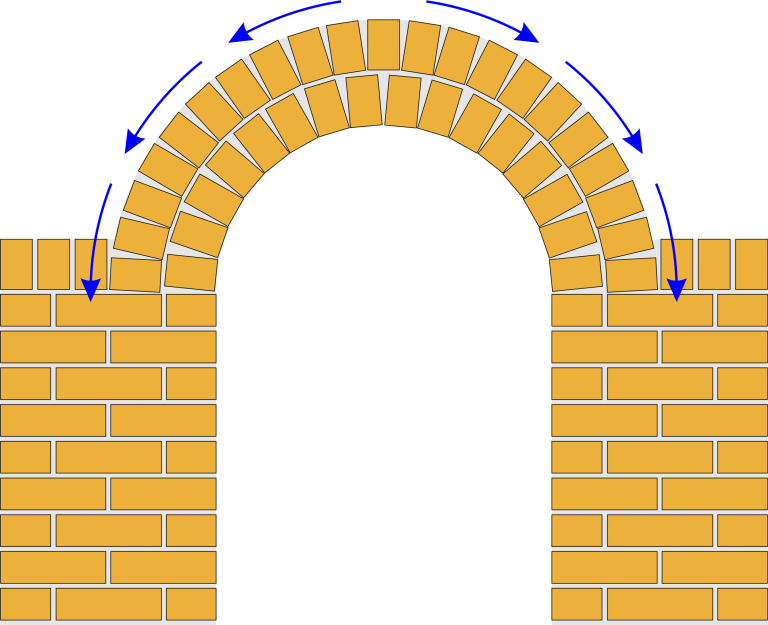

Distributes the Load on Arche

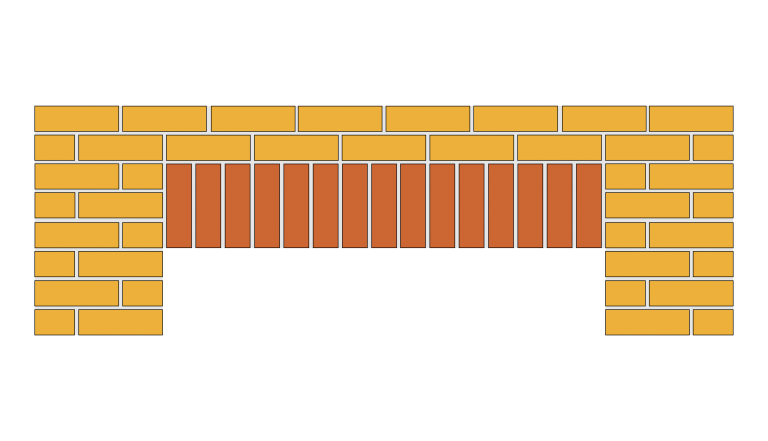

The curved shape of the arch distributes the load of the brickwork or stonework above the opening, down through the vertical sides of the opening.

If constructed correctly, the arch will not normally require additional reinforcement as some brick or concrete lintels do.

The small units of the arch are wedge-shaped and any load imposed upon the arch will compress these units further together.

When constructing arches, the brickwork or stonework will require some form of temporary support until the mortar is set and the shaped units are firmly secured in position.

There are many different types of arches that will bridge an opening, here are a selection of the most common arches you will find.

Skewback Arch

Semi Circle Arch

Gauged or Axed Arch

Soldier Arch

Axed Arch

Rough Ring Arch

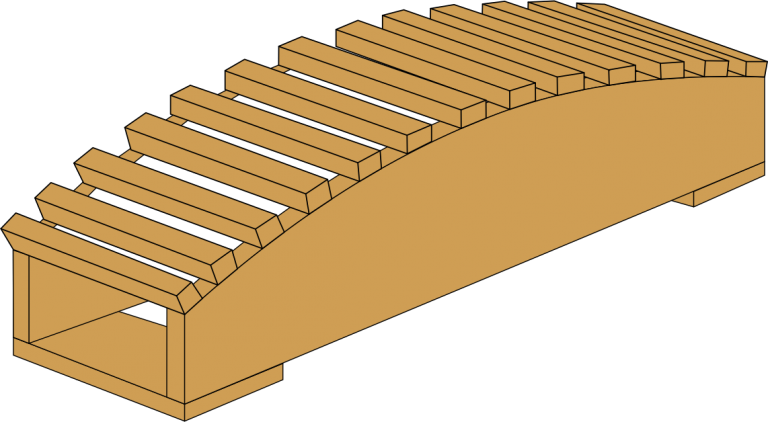

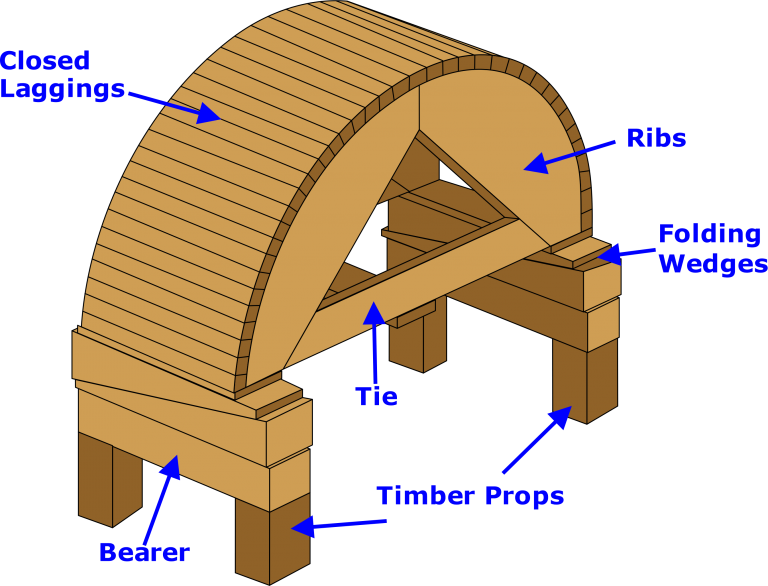

Turning Piece for Arch

In order to allow the arch centre or turning piece to be easily removed on completion of the arch, it should be supported on folding wedges placed on props or struts carefully wedged against the walls or abutments either side of the opening.

The term ‘folding wedges’ refers to a pair of wedges that are placed on top of each other, with their shallow taper in opposite directions.

These allow for fine height adjustment.

Centre for Arch

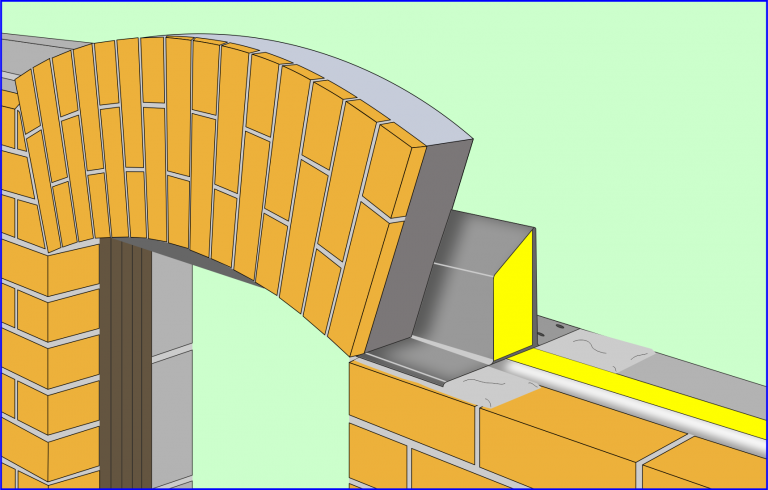

Preform arches are commonly used now which are made in a factory under ideal conditions and taking advantage of modern materials.

Manufactures can supply traditional arches or bespoke arches using less labour and to a consistently high-quality standard.

Preformed arches can even come with open joints for site pointing ensuring consistency in colour or pre-pointed coloured mortar.

Facing brick slips are approximately 25mm thick which is more than sufficient for pointing on-site.

Brick slips can be bonded to concrete or steel lintels including underslung soffit brickwork, segmental and cambered arches and stepped arches.

Preformed arches in most cases have insulation attached to them to reduce what is known as `Cold Bridge`going through the doors and window headers.

Moving preformed arches into position can normally be done by two personnel because of their lightweight construction methods, for heavier preformed arches when brick slips are bonded to concrete units they install eyepieces rods for mechanical lifting.

Preform Arch