Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

This is necessary to comply with the Personal Protective Equipment Regulations 1992 which, from 6 April applies to the provision and wearing of head protection on construction sites following the revocation of the Construction (Head Protection) Regulations 1989.

Employers have a legal responsibility to provide their employees with suitable head protection under the rules made or directions given under regulation 5 of these Regulations.

No Employees under the Health & Safety Work Act 1974 must not misuse any Personal Protective Equipment (P.P.E.) provided by their employer.

All construction sites employees and employers or visitors must wear a safety helmet on site which is necessary to comply with the above regulations.

Objects falling from height can be minimised by using scaffolding with toe boards and brick guards which minimises head injuries but there remains a risk of falling objects like tools, bricks and other building materials.

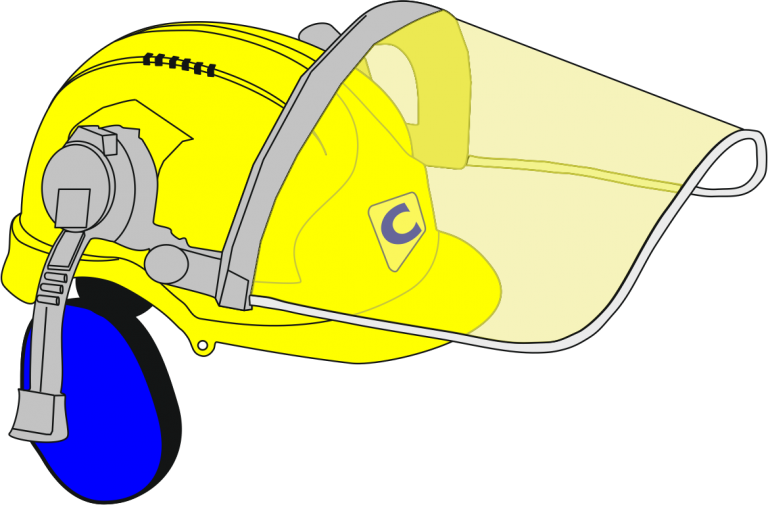

Some safety helmets incorporate or can be fitted with specially-designed eye or hearing protection.

Don’t forget neck protection, eg scarves for use during welding

During inspection you may have to replace certain components like:

Safety Helmet Harness with Ratchet Adjustment

Replacement Sweatband

Centurion Hi-Vis Sun Cape

Elasticated Helmet Chinstrap

It may well be it will be cheaper to replace the safety helmet than getting replacement parts, you also need to have a look at the manufacturing date generally hard hats lasts for 3 to 5 years from the date.

Since regulations came into force many lives have been saved on construction sites.

An exception to the regulations are Sikhs who wear turbans, they are not required to wear safety helmets on a construction site.

Testing Safety Helmet

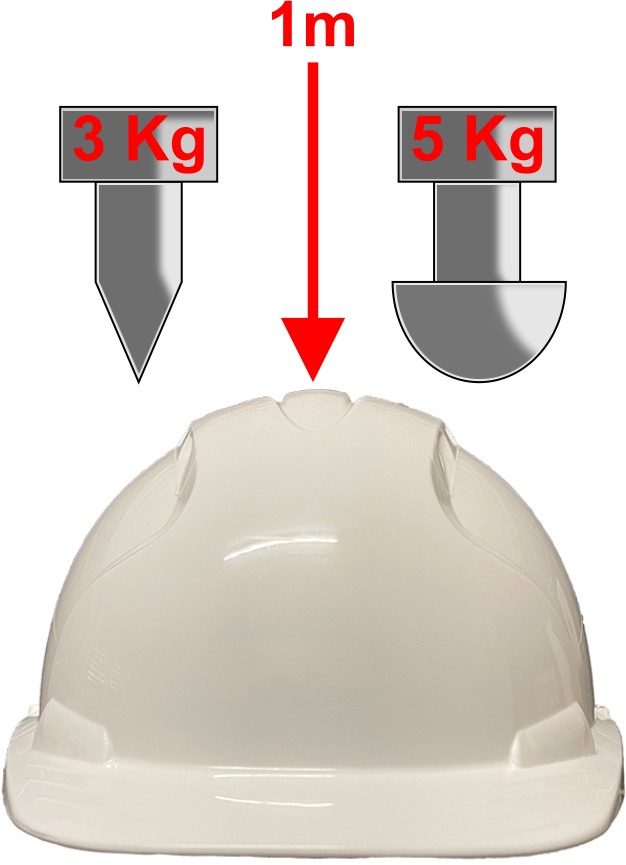

All safety helmet should be able to protect the wearer from the following:

Resist penetration by objects,

Absorb the shock of a blow,

Be water-resistant and slow-burning, and come with instructions.

Test centres placed a safety helmet loaded with detectors and place it onto a head shaped mould.

Several tests are repeated in high and low temperatures as well as being immersed in water and exposed to UV rays.

Shock absorbent test is done with a 5kg rounded strike dropped from 1 m high, impact tests replace the round strike with 3kg pointed end and drop from the same distance, if the point penetrates the safety helmet it fails.

Build UK introduce a colour-coded system for safety helmets they are the leading representative organisation for the UK construction industry, their member sites and the construction industry as a whole follow their colour scheme.

This ensures consistency and a unified understanding across construction sites, as the colours each represent a certain role or status.

This is an additional layer to Health & Safety enabling supervisors to quickly identify key workers also in the event of an emergency.

Slingers & Signallers

First Aiders

Fire Marshall

Site Visitors

Site Supervisors

Site Managers

ICE Sticker

Unfortunately, accidents do happen on construction sites and in the case of emergencies (ICE) sticker for accident victims gives the on-site medical team member or attending ambulance staff instant access to the victims potential lifesaving information and enables emergency contacts to be quickly notified of the situation 24/7.

This type of sticker will not weaken or damage the material of the helmet in any way.

The sticker can be placed inside or outside of the helmet, and the sticker is waterproof which safeguards personal information which is hidden until required by emergency services.

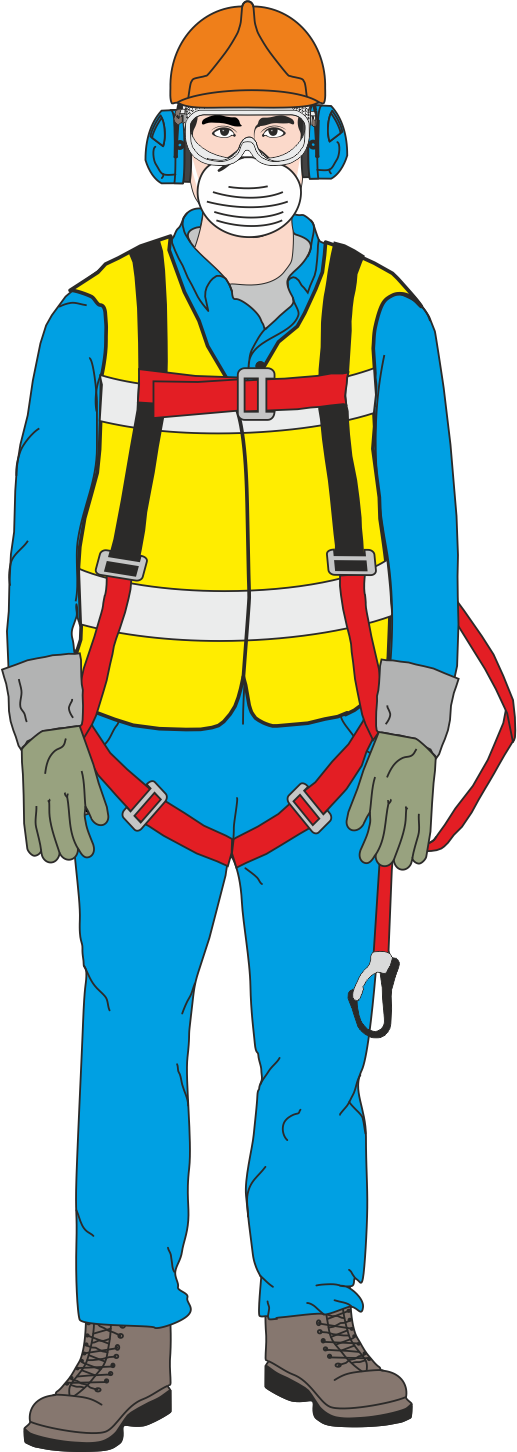

Worker wearing PPE

It is your responsibility to check all Personal Protection Equipment (P.P.E.) before use.

At any one time you will have several different types of P.P.E. depend upon the hazards in your work activity, some common P.P.E. such as Hi-visibility Jackets, Safety Footwear, Safety Helmets and Eye or Ear Protection through to very specialist equipment such as Fall Arrest Harnesses and Specialist Respirators.

All personal protection equipment must fit the wearer enabling the wearer to perform these tasks safely.

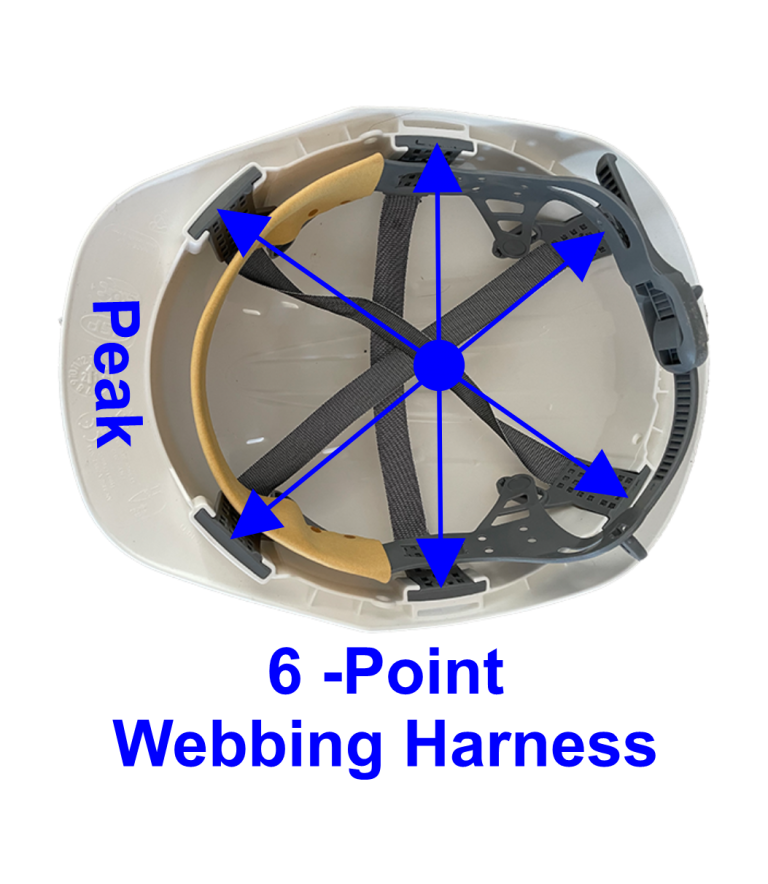

Safety Helmets should be worn correctly according to manufacturers instructions with the peak facing forward.

Damage Safety Helmet

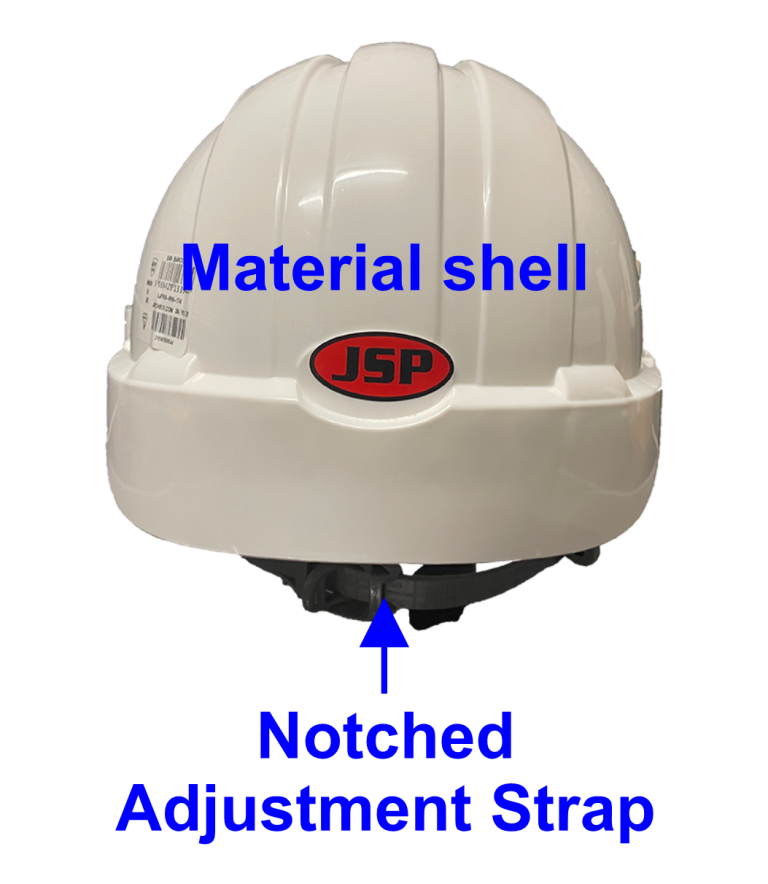

Safety helmets are vulnerable to physical and chemical damage and checked for signs of obvious damage like cracks, holes and chemical damage.

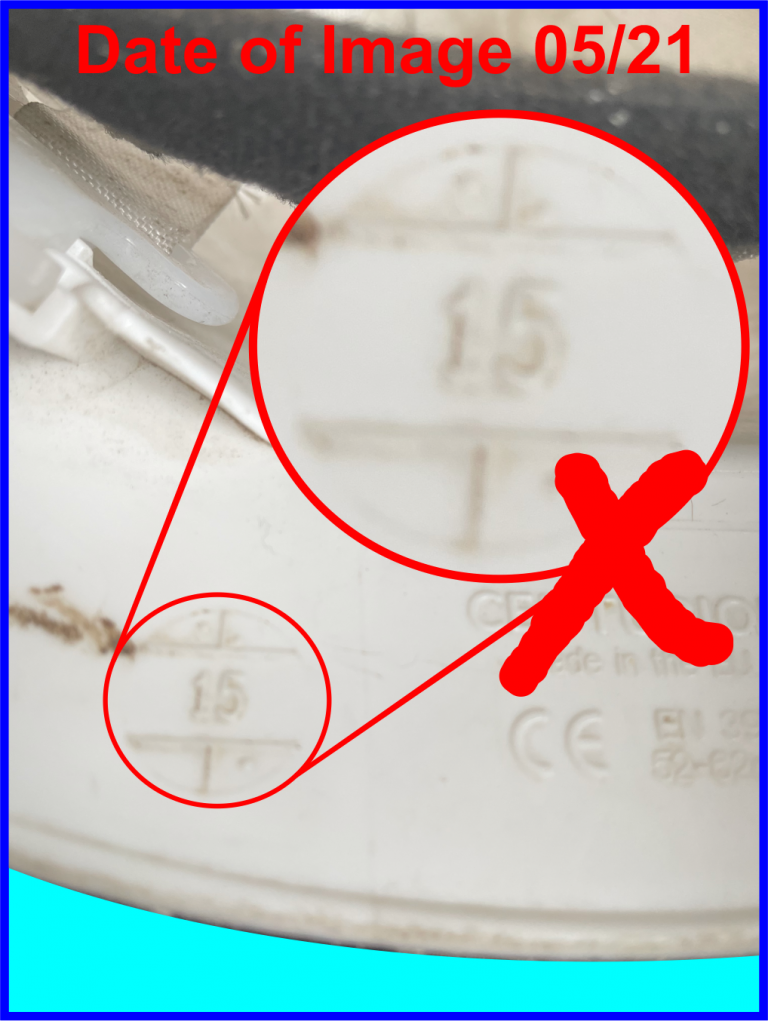

Best Before Date

One of the most important checks that are overlooked is the expiry date on a safety helmet because safety helmets are made from plastic and materials that deteriorate over time they have a limited shelf life.

Safety Helmets Out of Date

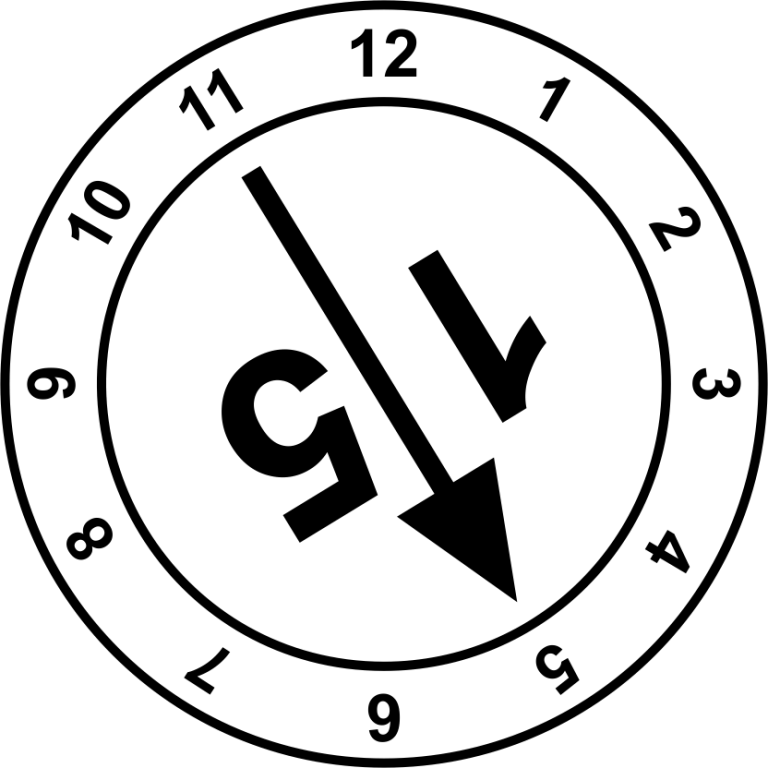

Month & Year Ring

Generally, expiry dates can be found underneath Material shell by the peak/brim of the safety helmet this will include additional manufacturers information.

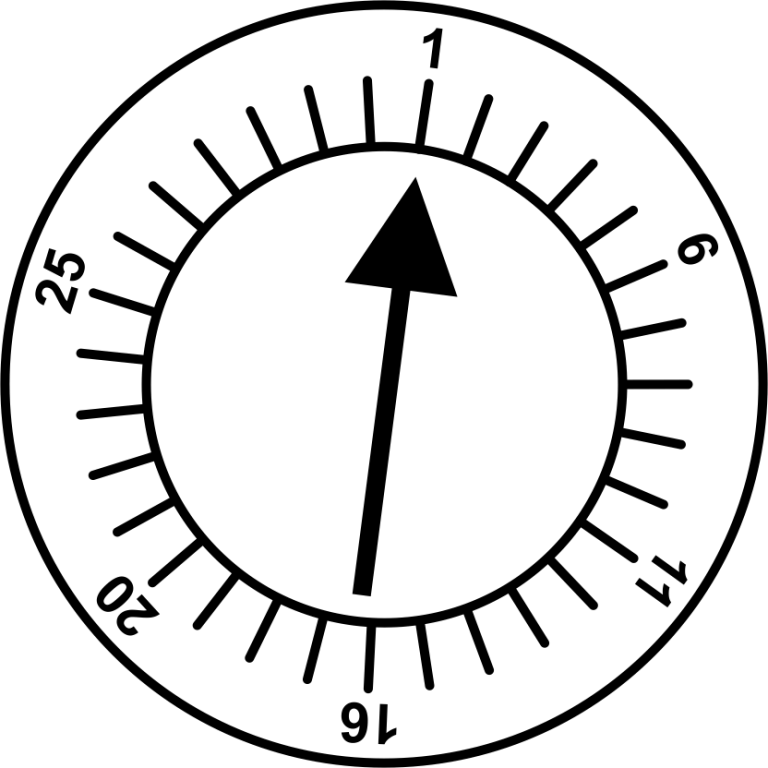

Most manufacturers supply the date of manufacture using two circles one being the day and the other being the year and month.

Here is an example

The day ring is divided into 31 days, points to the first day of the month, the second Month/Year Ring points to figure 5 indicating the month of May and the year of manufacture is 2015, which has a figure 15 through the pointer.

Therefore, manufactured date is 1 May 2015, most safety helmets have a shelf life of 5 years can be lower but you need to consult the manufacturer’s information.

Day Ring

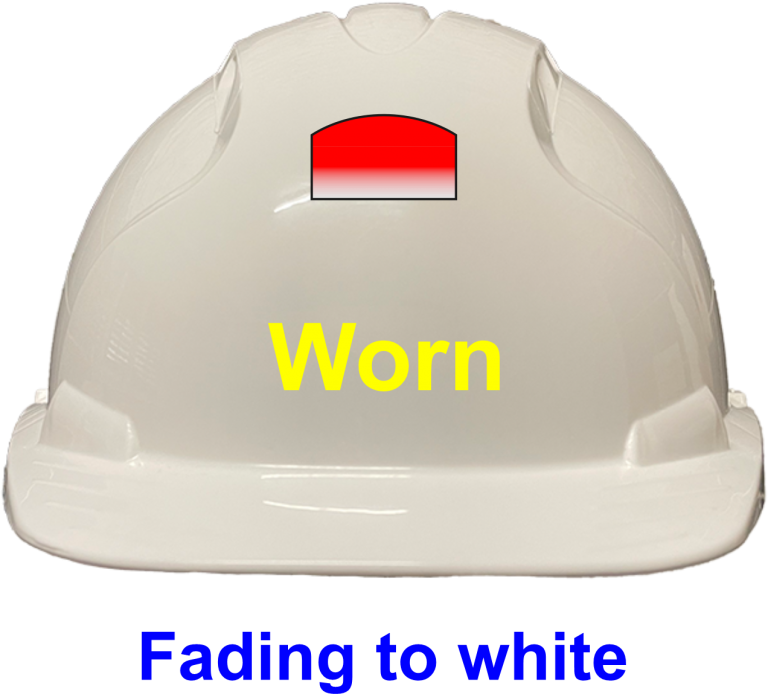

Hidden hazard UV exposure to the sun can also be damaging to a safety helmet’s protective performance, compromising the safety of the wearer not knowing when to replace the safety helmet.

To help the wearer combat this hazard on some hard hats, ave a Uvicator circular red disc strategically placed slightly below the highest point of the helmet.

As the helmet is exposed to sunlight, the disc is calibrated to detect the amount of UV radiation received and gradually changes colour over time, clockwise, from red to white.

A completely white disc indicates that the safety helmet has received maximum tolerable radiation, and therefore needs to be replaced.

Manufacturers fix approve stickers like First Aiders, Fire Marshall, Do Not Use unapproved stickers the adhesive may degrade the material shell of the Safety Helmet.

Do not clean the Safety Helmets with chemicals or abrasive cleaners.

Safety helmet should be stored out of direct sunlight and away from any chemicals and extreme temperatures.

Safety Helmets should only be cleaned with soap and water and dried with a soft cloth.