Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

1. understand how to plan and select resources for practical tasks

The learner can:

Falling from Height

Who might be harmed and how?

Serious injury or even fatal injury could occur if a worker falls.

What are you already doing?

• Agree to scaffold requirements at contract stage, including appropriate load rating and provision of loading bays.

• Bricklayers’ supervisor to check with the site manager that the correct scaffold is provided and inspected.

• Workers instructed not to interfere with or misuse scaffold – supervisor to keep an eye out for problems.

• Ladders in good condition, adequately secured (lashed) and placed on a firm surface.

• Bandstands with handrails to be used for work on internal walls.

• Workers trained to put up bandstands.

What further action is necessary?

Scaffold requirements agreed, including loading bays and appropriate load rating.

Supervisor to speak regularly to the site manager to arrange scaffold alterations and ensure that weekly inspections have been carried out.

Collapse of Scaffold

Who might be harmed and how?

All operatives on a scaffold may incur crush injuries, Who might be harmed and how?

• Agree to scaffold requirements at contract stage, including appropriate load rating and provision of loading bays.

What further action is necessary?

• Bricklayers’ supervisor to check with the site manager that the correct scaffold is provided and inspected.

What are you already doing?

Supervisor to keep a check to make sure that scaffold is not overloaded with materials.

Falling objects hitting head or body, including feet

Who might be harmed and how?

Serious head and other injuries to workers, others on site and members of the public.

What are you already doing?

• Brick guards kept in position on scaffold lifts.

• Waste materials removed from scaffolding and placed in the skip.

• Safety helmets and protective footwear (with steel toecaps and mid-soles) supplied and worn at all

• Bricklayers’ supervisor to check with the site manager that the correct scaffold is provided and inspected.

What further action is necessary?

Supervisor to monitor the use of safety hats and protective footwear.

Manual Handling

Who might be harmed and how?

All workers could suffer from a back injury and long-term pain if regularly lifting/ carrying heavy or awkward objects.

What are you already doing?

Bricks, mortar etc to be transported and lifted to scaffold using telehandler provided by the principal contractor.

• Provision of lifting bay agreed with the principal contractor.

• Bricks/blocks to be covered with a tarpaulin when stored on-site to prevent taking up water.

• Spot boards to be raised with blocks to easy working height.

• Trolley to be used for moving loads of bricks around the scaffold lift.

• Check at a tender stage for any blocks or lintels over 20 kg and make arrangements.

What further action is necessary?

Heaviest blocks are 15 kg, no special arrangements necessary.

Concrete lintels are well over 20 kg, to be positioned using telehandler (all are accessible).

All workers to be instructed not to carry materials up by hand.

Workers struck or crushed by moving vehicles on site

Who might be harmed and how?

Workers could suffer serious or even fatal injuries from vehicles and machines on-site – particularly when reversing.

What are you already doing?

Manager to agree on a safe route to the work area with a principal contractor based upon the construction phase health and safety plan.

• Induction to each site to be carried out for all workers on the first day.

What further action is necessary?

Safe route agreed with the principal contractor

Supervisor to liaise with the site manager to ensure safe route stays clear.

Instruct staff that they must never drive vehicles and plant on this site.

High-visibility vests to be provided.

Supervisor to check vests are worn on all sites where the principal contractor requires them.

Slips and Trips

Who might be harmed and how?

All workers could suffer foot injuries.

What are you already doing?

• Safety boots with steel toecaps and mid-soles provided to all workers.

• Waste disposed of in skips.

What further action is necessary?

Explain the need to wear safety boots and dispose of waste in skips – repeat annually.

Supervisor to check that safety boots are always worn and waste disposed of properly.

Stepping on Nails or Sharp Objects

Who might be harmed and how?

All workers may suffer sprains or fractures if they trip over waste including brick bands and pallet debris. Slips at height could result in a serious fall.

What are you already doing?

Good housekeeping maintained at all times.

• Waste including brick bands and pallet debris disposed of in a skip.

• Safety footwear provided to all workers.

• Safe route to workplace agreed with a principal contractor based on construction phase health and safety plan.

What further action is necessary?

Temporary storage locations to be agreed with the site manager.

Supervisor to ensure that workers wear safety footwear whenever on site.

Hazard to Eyes, Cutting Bricks

Who might be harmed and how?

Bricklayers could suffer eye injury through flying brick fragments.

What are you already doing?

• Safety goggles (EN 166 B standard) worn when breaking bricks.

What further action is necessary?

Use of goggles to be monitored by a supervisor.

Hazardous Substances, Mortar

Who might be harmed and how?

Direct skin contact with the mortar could also cause bricklayer contact dermatitis and burns.

What are you already doing?

• Risk of dermatitis or cement burns and precautions explained to all workers.

• Use cement or cement containing products within the use-by date.

• Direct skin contact to be avoided, CE marked PVC gloves used when handling mortar.

• Good washing facilities on site, with hot and cold water, soap and basins large enough to wash forearms.

• Principal contractor’s first aid includes emergency eyewash.

What further action is necessary?

Training on how to treat exposure to be given to all operatives.

Supervisor to be aware of anyone with early signs of dermatitis.

Dust from Cutting Bricks

Who might be harmed and how?

Dust exposure could cause silicosis.

What are you already doing?

• Angle grinders replaced with block splitter, removing the risk of significant dust exposure.

• The use of a grinder for chasing etc is not needed on this job

Operating Cement Mixer

Who might be harmed and how?

Workers could be crushed or cut if the mixer topples or they get caught in moving parts. Damage to electrics could result in a shock.

What are you already doing?

• Cement mixer located on firm, level ground.

• Mixer is fully guarded and guards in place during operation.

What further action is necessary?

Supervisor to check mixer daily for obvious damage.

Noise from Using Equipment

Who might be harmed and how?

Supervisor to check mixer daily for obvious damage.

What are you already doing?

• Angle grinders replaced with block splitter, removing high noise levels from our work.

• Construction phase plan show other trades using grinders etc should not be working close enough to cause problems.

What further action is necessary?

Supervisor to monitor and talk to site manager if noisy work does start close by.

Vibration from Using Equipment

Who might be harmed and how?

Exposure to vibration can lead to the development of ‘vibration white finger’ (VWF).

What are you already doing?

• Angle grinders replaced with block splitter. No significant vibration left.

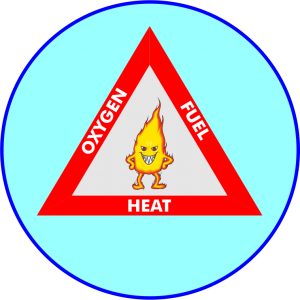

Fire or Explosion

Who might be harmed and how?

All operatives in the vicinity could suffer from smoke inhalation or burns.

What are you already doing?

• All operatives in the vicinity could suffer from smoke inhalation or burns.

What further action is necessary?

Supervisor to brief all workers on the first day on emergency arrangements agreed with the principal contractor.

For additional information go to the following link and subheadings on

Risk Assessments & Method Statements @