Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

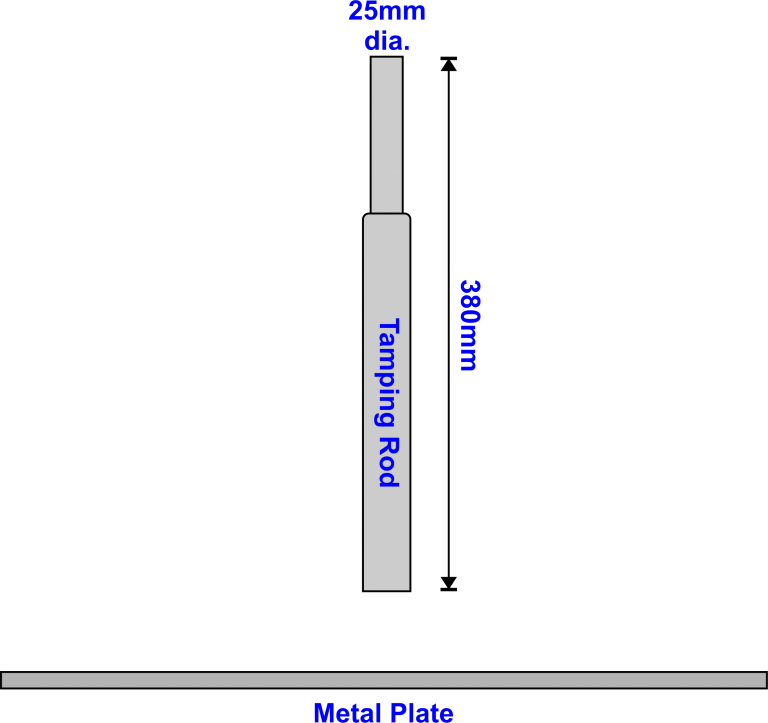

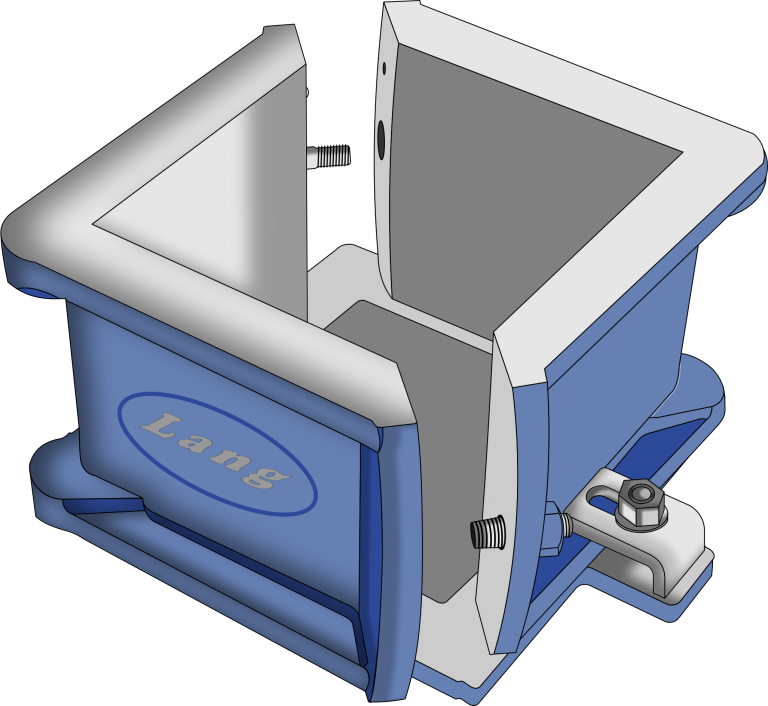

You will need this equipment

(always clean and dry the equipment after use)

Step 1

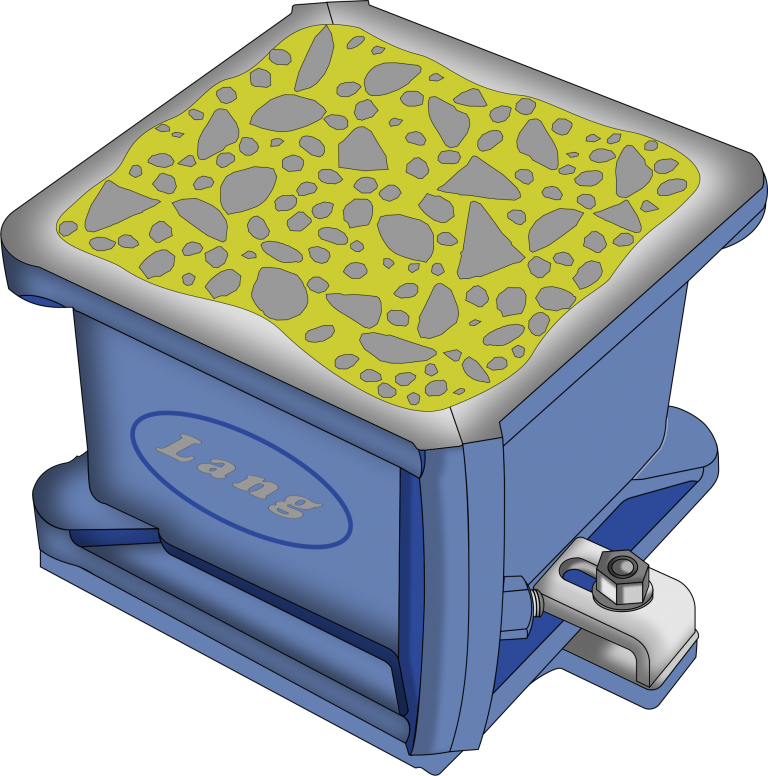

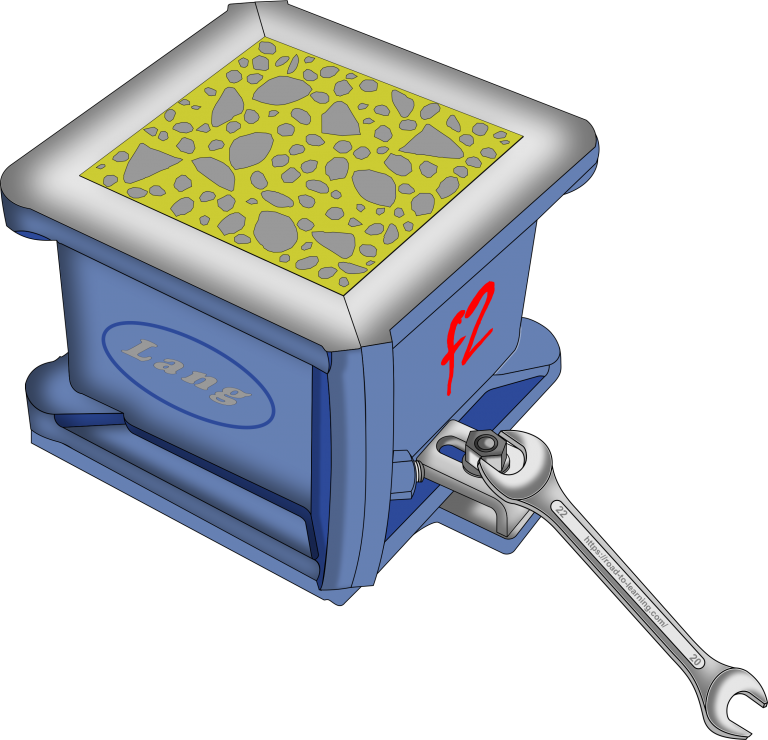

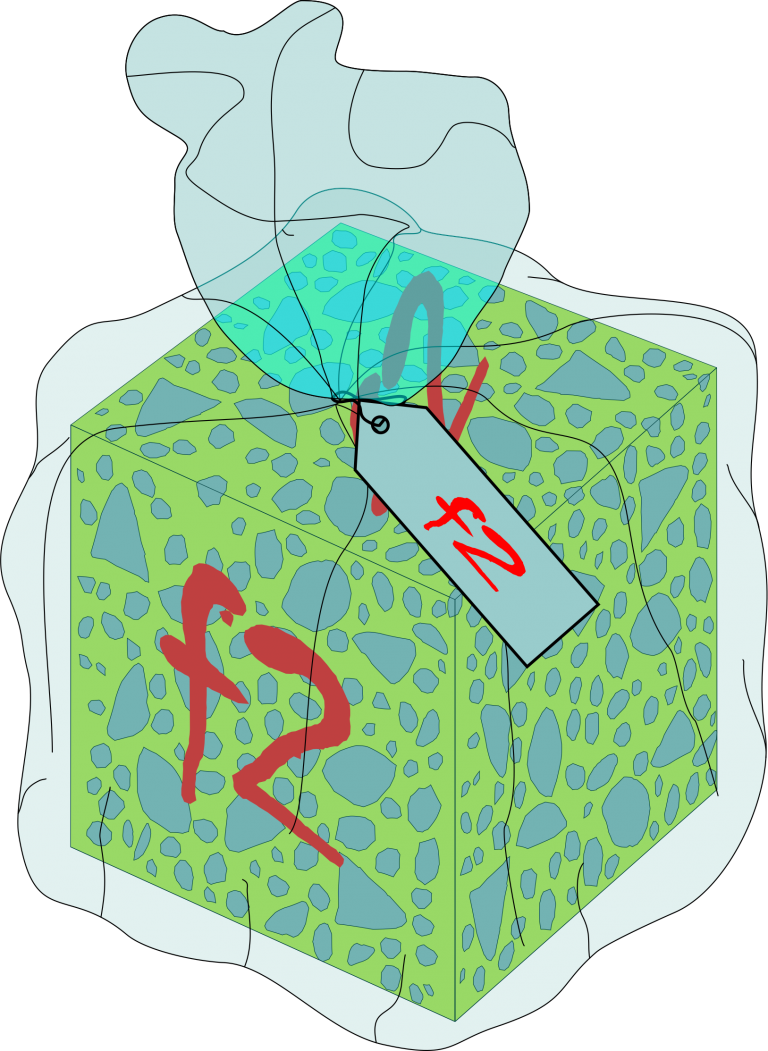

Aggregate size up to 40mm use 150x150x150mm cube mould,

Aggregate size up to 20mm use 100x100x100mm cube mould

internal faces of the mould are lightly oiled prior to receiving concrete

Concrete Cube Mould

Step 1

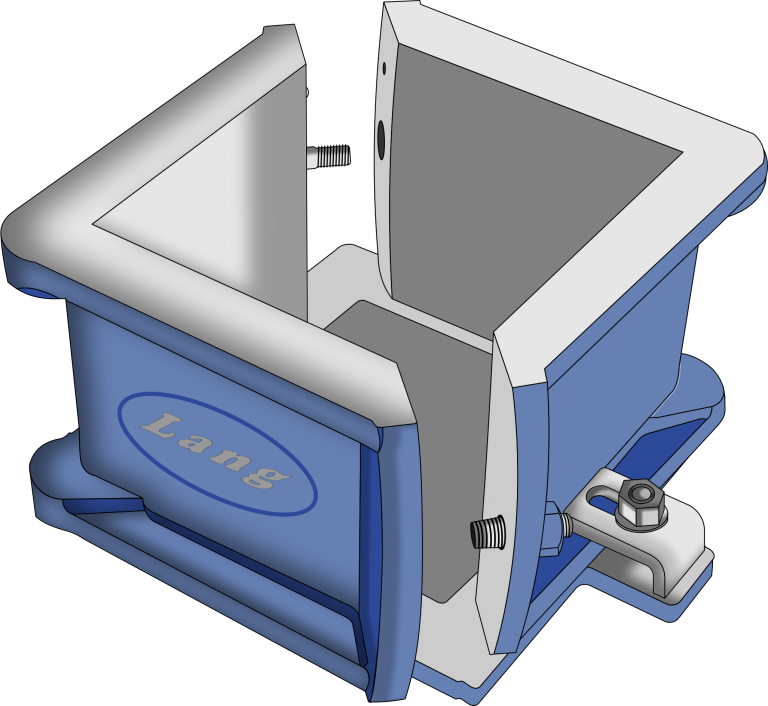

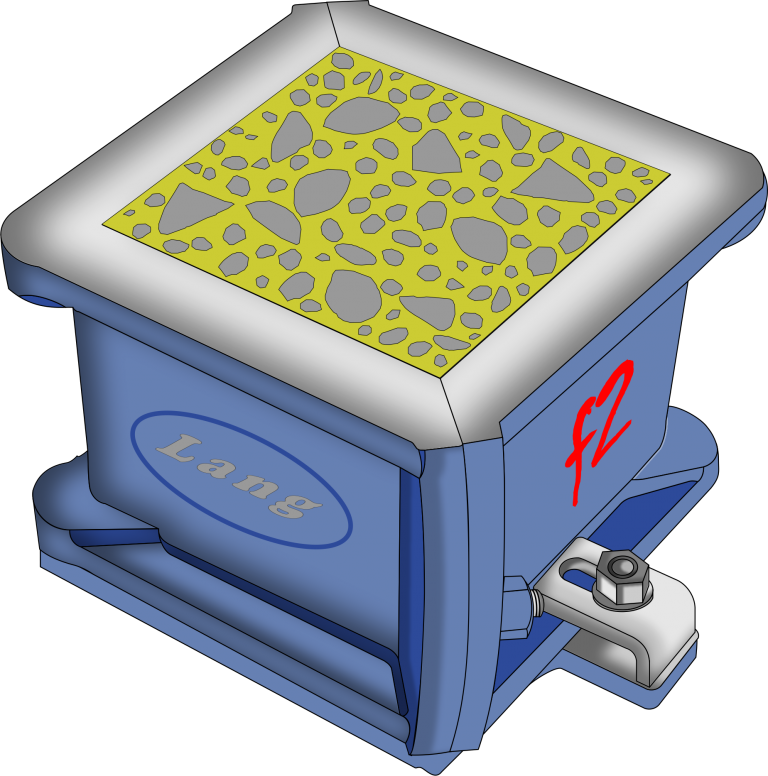

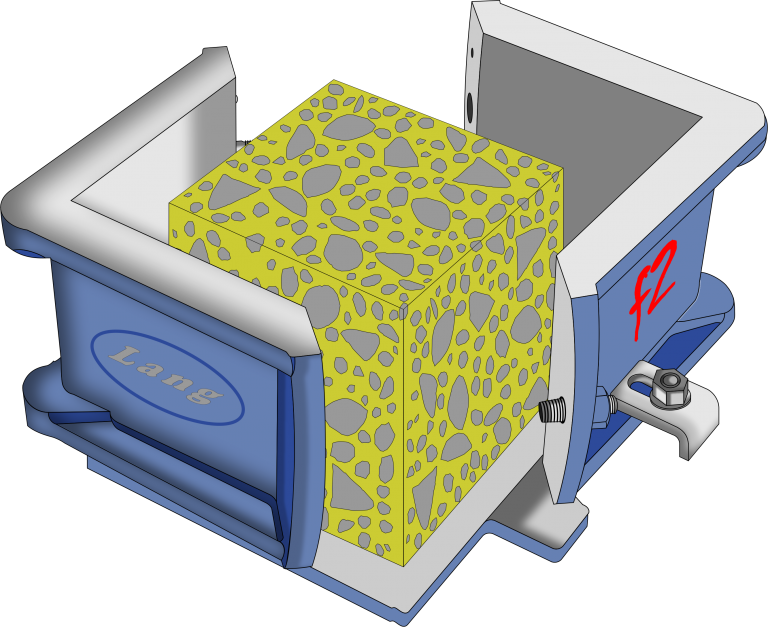

Check that the moulds are clean and lightly oiled with all bolts tightened so that there will be no leakage.

Ensure that the correct halves of the mould are used and that the corner lining pins are correctly located.

Thoroughly remix the sample as described for the slump test.

Fill the mould with concrete in 50mm layers.

Using the special tamping bar.

Compact the concrete with not less than:

25 tamps for each of the two layers in a 100mm mould

35 tamps for each of the three layers in a 150mm mould

Step 2

Step 3

Remove the surplus concrete and smooth it over with a steel float.

Remove the surplus concrete and smooth it over with a steel float.

Step 4

Step 5

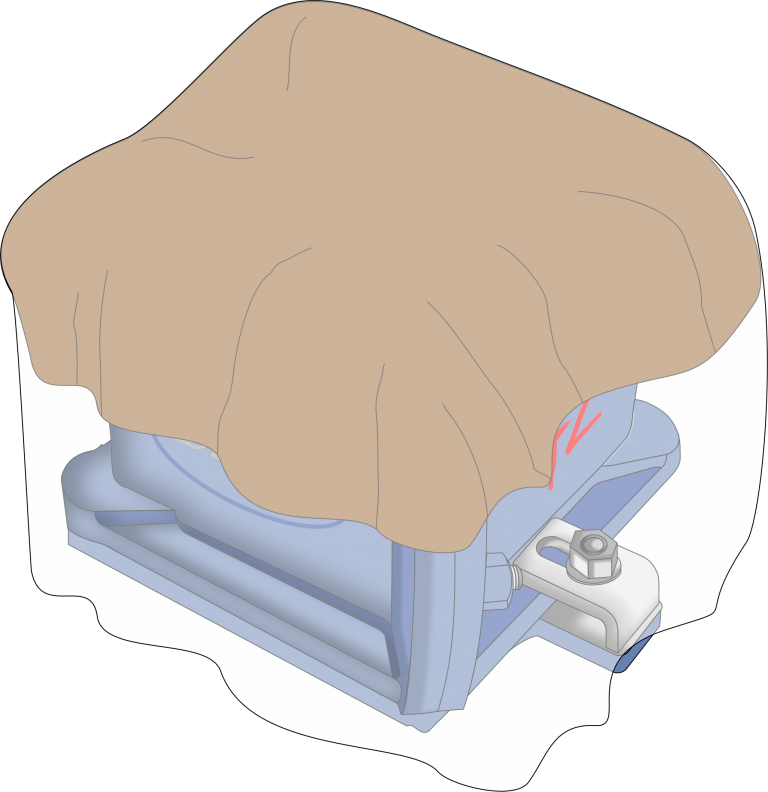

Cover each mould with a damp cloth and plastic sheet.

Store inside at normal room temperature (15°C to 25°C) e.g. on top of the curing tank

Protect the cube moulds at all times from high and low temperatures (especially frost) and drying winds

Complete the Sampling and cube making certificates

Step 6

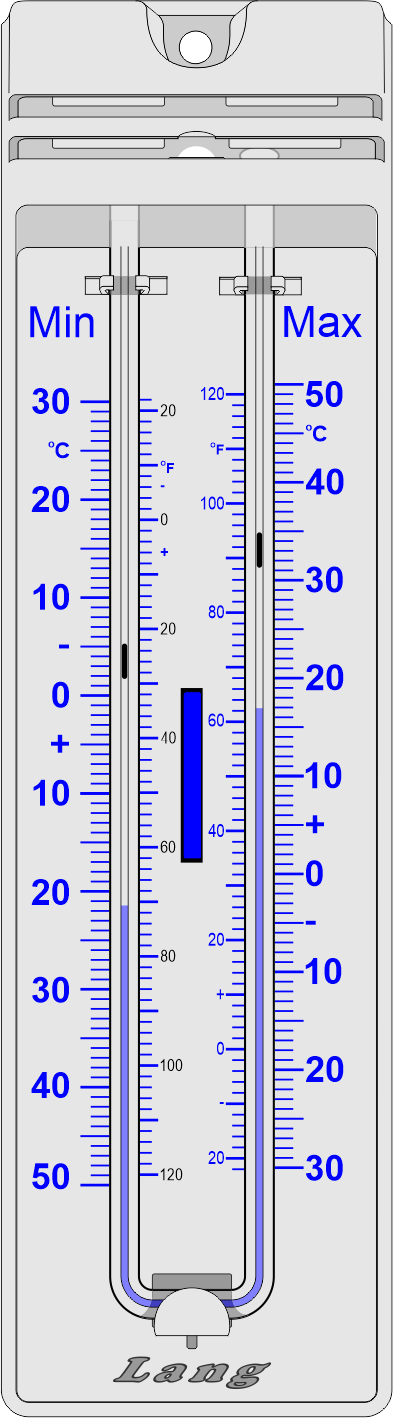

Record the max/mini overnight storage temperatures on the certificate.

The samples remain in the mould for 24 hours.

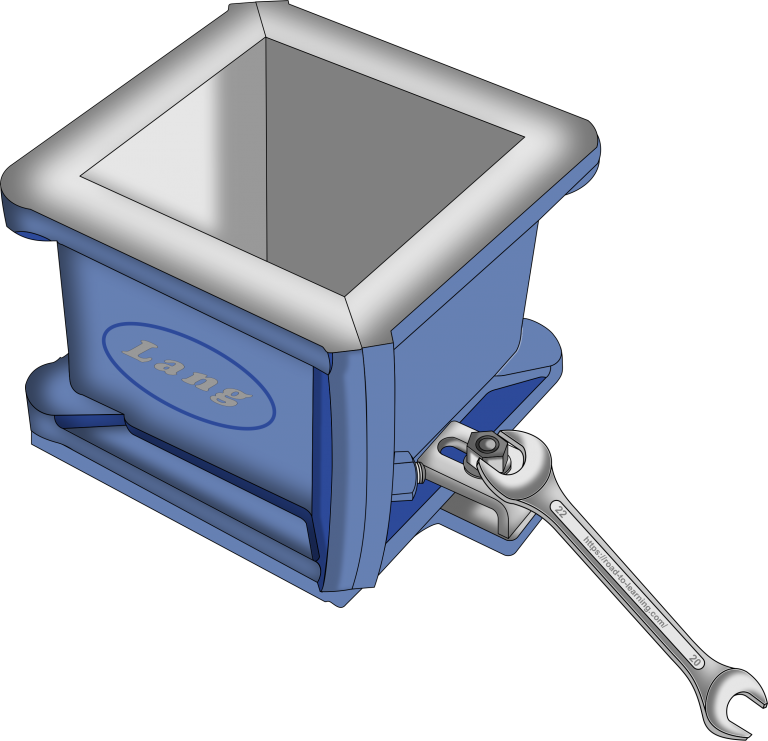

Slacken all nuts.

Step 7

Part the sides of the mould, tapping gently with Rubber Mallet and lift off carefully.

Remember, new cubes are easily damaged unless handled carefully.

Step 8

Step 9

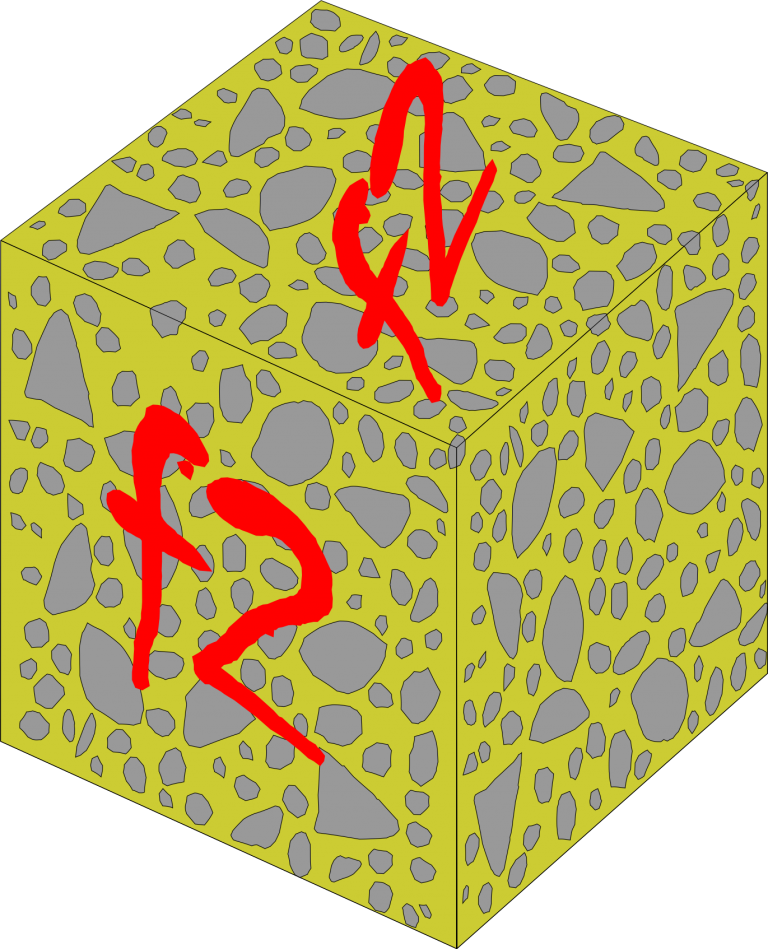

Mark each cube with its identification number on two of its cast sides.

Submersed in water at a temperature between 10°C to 21°C until required for testing.

Clean and reassemble the moulds.

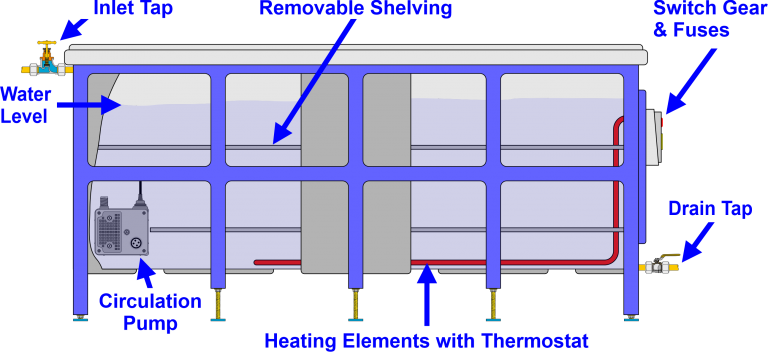

Concrete Cube Curing Tank

Check that the water temperature is controlled at 20°C ± 2°C and the cubes are covered by water.

Make sure the power supply is not switched off day or night.

Check the temperature range daily using the maximum/minimum thermometer.

Keep a record of the readings

The cube is despatch to the test laboratory for the 7-day Compression strength test.

Wrap the wet cubes in damp cloths, and then plastic bags and pack in trays.

Attach the sampling testing and the cube making and storage certificates, plus the order for testing, to the package.

Step 10

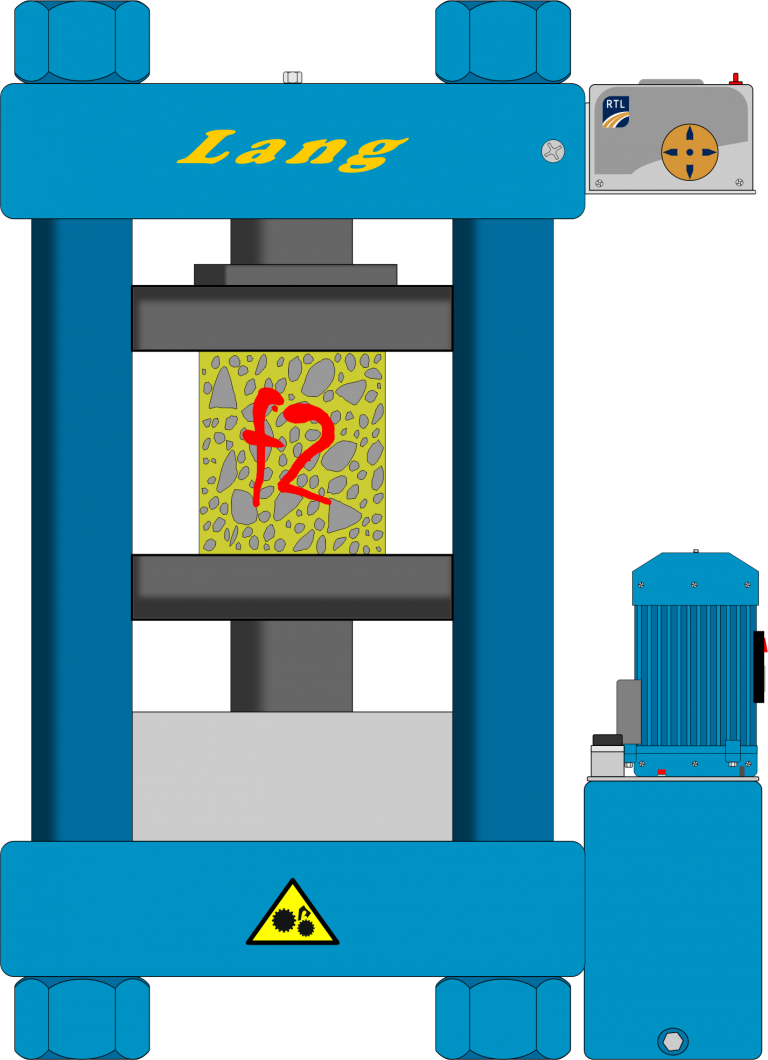

Concrete Compression Strength Test

If the Compression strength test fails then a further test is undertaken at 28 days, specimen cores may be taken from the placed concrete for laboratory analysis.

Additional learning resources for this Post can be found on the following links