Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

1.3 Identify the Tools & Equipment required to build following units in brickwork qualifications.

Unit 005 Constructing Half Brick Walling

Unit 118 Constructing Block Walling

Unit 119 Constructing Half Brick Return Corners

Unit 120 Constructing Cavity Walls in Brickwork & Block Work

Unit 121 Constructing One Brick Walling

P.P.E.

In addition to gloves and safety footwear, it is necessary to wear goggles when cutting bricks and blocks because of the risk of splinters flying from the cutting process.

Observers should be protected against this hazard.

Although there is some impact noise hammer to chisel and chisel to brick it is not usually necessary to wear ear defenders.

Additional information on Mandatory Signs go to (Mandatory Signs)

Club or Lump Hammer

To cut the bricks or blocks accurately we need a club or lump hammer and a brick bolster.

A brick hammer and a scotch hammer sometimes called a comb hammer are used to trim and shape bricks or blocks.

Lump hammer Have different weights the popular weights are: 2 lb, 2.5 lb, 3 lb, 4 lb for use with cold chisels and bolsters.

It is essential that the head is secure and checked regularly to ensure it never comes loose.

Do not hit bricks and blocks with the end of the handle nor the faced sides with the hammer head.

Their head of hammer must not be used to hit the faces of bricks and blocks.

Clean hammers daily also check that their head has not become loose and periodic soaking in water will prevent the head from working lose.

Never hit two hammer heads together to hear the ring or feel the bounce.

Sharp pieces of metal can fly off at great speed, seriously slicing anybody in contact with them.

Do Not Do This

Scutch Hammer

A scutch hammer may have two grooved ends to receive replacement steel blades or replacement combs for trimming or cutting bricks or blocks when cut with bolster.

The square blade is used in the same way as a brick hammer.

The blades are simply knocked sideways and turned round all replaced as necessary.

A periodic soaking in water will prevent the head working lose

Brick Hammer-Designed for cutting and setting bricks or blocks, and for chipping mortar.

The square end of the hammer is used for knocking in nails.

A periodic soaking in water will prevent the head working lose.

Sharp pieces of metal can fly off at great speed, seriously slicing anybody in contact with them.

Brick Hammer

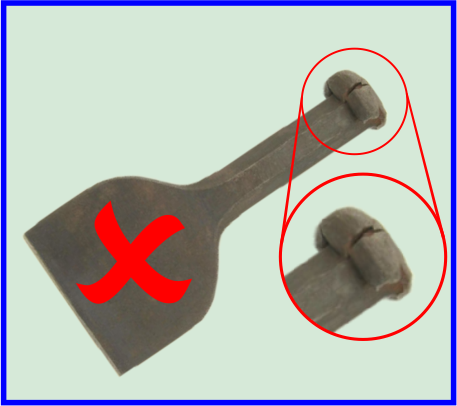

Bolster

Used for cutting bricks and concrete blocks.

Eye protection must be used at all times it is used.

The end of the handle should never be allowed to burr over after repeated hammering.

This is known as a Mushroom Head and can splinter when being hit.

The handle end should be kept free from Mushroom Head by a grinding wheel which can also be used to keep the cutting edge sharp.

Bolster

To build any wall we need a trowel to lay the bricks or blocks, and for the face brickwork, a pointing trowel and a jointer to provide a finish to the joints.

Brick Trowel

These come in various shapes and sizes ranging between ten and fourteen inches.

One side of the trowel has a more rounded edge, this being for rough cutting, however, this use is not advised for the beginner.

The measurements are the actual blade size, the width of trowel also varies and beginners will find a narrower trowel easier to use.

The rounded side on the trowel makes it suitable for both left and right handed operators.

When the trowel is not in use for a period of time, clean it off dry and apply a light coat of oil to avoid rusting.

Pointing trowels generally range in size from 75 mm to 150 mm blade length. They are used to fill any small gaps in the mortar between bricks/blocks and for producing the required pointing of the joints, e.g. weather struck, ruled.

Pointing Trowels

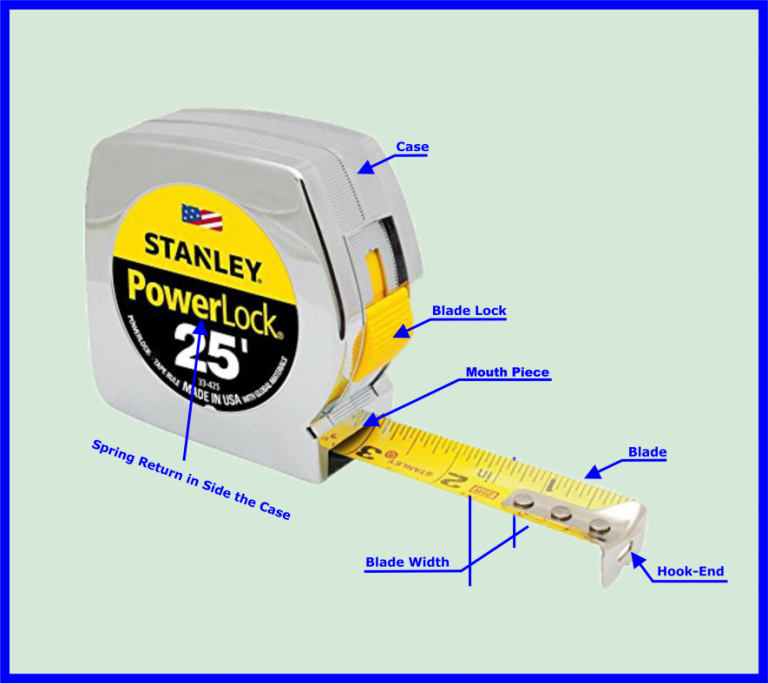

Pocket Tape Measure

A Tape Measure are needed to set out and check dimensions and cutting components.

Tape measures come in different sizes and different materials they also can have combination of metric and imperial measurements or just metric.

Components of a Tape Measure

The blade lock is useful for repetitive measuring and also enables easier reading when measuring in restricted or confined spaces where the blade may be locked in the measuring position but read away from the work.

A spring return refers to an automatic spring return mechanism when the blade is rewound.

Tapes without automatic return are sometimes described as ‘pull-push’.

Spring return tapes should not be allowed to fly back uncontrolled from the extended position to prevent hook/blade damage.

Two kinds of spirit level are used. One is a long level, usually of metal, with bubbles that show horizontal and vertical levels.

Lengths vary but the favourite length for brickwork is 1200 mm long.

Spirit Level

Boat levels

The other is the boat level, which again has a horizontal and a vertical level.

It is usually made of wood with a brass face and is about 225 mm long.

Long levels are used for checking courses and facework for level and straightness.

These are used as a wall is being built up to provide a guide for the bricks between the pins.

The pins are tapered at the ends to allow them to be inserted into mortar joints.

It is important that the line is kept free of knots and clean of mortar.

Line and Pins

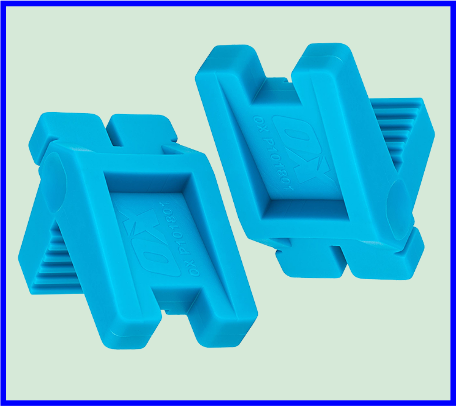

Corner Blocks

These are made from Hardwood, Plastic or Rubber Line Block and are used in pairs in conjunction with a building line to enable the line to be stretched taut between corners or, in this case, from end post to end post.

The line is fixed to the corner block by running it along the central slot lengthwise down the block then wrapping it around the end and passing it across the transverse slot to lock it.

For additional information on Line, Pins and Corner Blocks following the links below

Used for putting a finish to the joints in brick work.

A half-round joint is also known as a bucket handle finish.

Two types are shown, these can now be bought from shops but an old pail or bucket handle can be bent to a suitable shape.

Jointing Tools

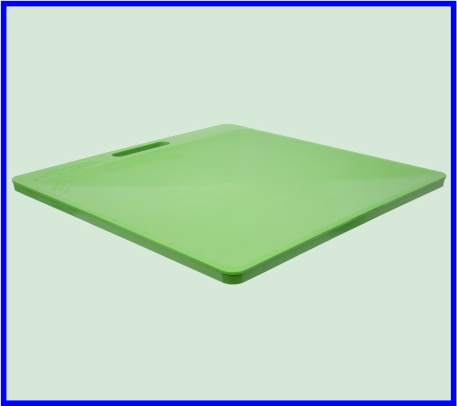

Mortar Board

Mortar Board or Spot Boards for many years bricklayers use a piece of timber to keep the mortar on so the bricklayer can get a Full Trowel to spread the on the wall.

Traditionally bricklayers had to wet the timber so timber boards didn’t absorb the water content from the mortar degrading the work ability of the mortar mix.

Nowadays we have polyethylene and steel mortar boards which help mortar and other building materials to retain more moisture.

Mortar boards need to be raised off the ground

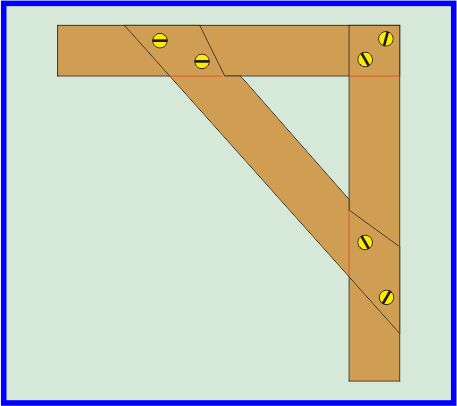

The Builders Square is used for the setting out process when constructing brick or concrete block walls.

You need to check the building square before using it to ensure it is still at 90° using a 3,4,5 method before use, ideal for corners and where walls meet.

For more information on how to check your building square for advocacy go to the following link

Builders Square

Masonry Saw

Suitable for cutting through aerated concrete blocks.

Features tungsten carbide welded blade tips for maximum cutting strength.

The Construction Skills (6219) only requires bricks to be laid to line.

There is no requirement to plumb ends or to build corners.

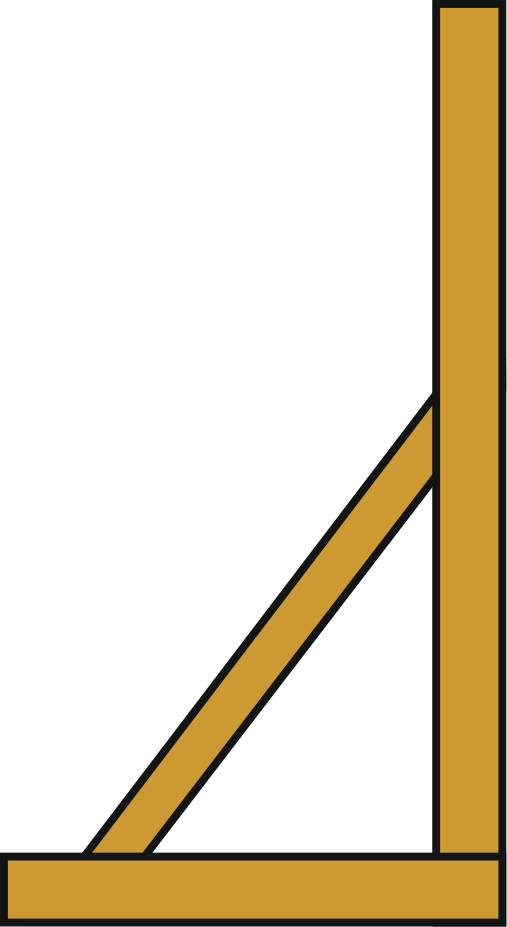

End stands can be constructed which can then be used in pairs to provide vertical ends between which students can lay bricks to bond, gauge and line.

A height of 675 mm only, for both bricks and blocks, is required to meet the Construction Skills (6219) criteria and end stands 1 metre high will be adequate.

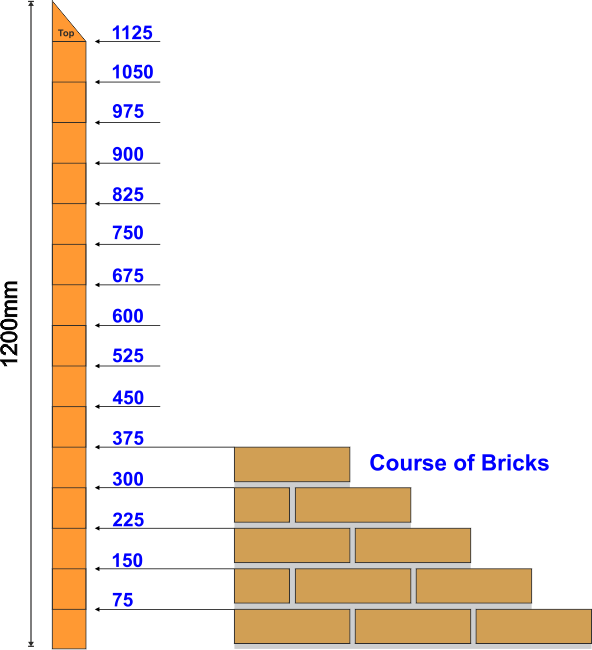

A gauge rod is constructed from a piece of timber approximately 1 metre long and 50 x 25mm in size, marked off in brickwork gauge.

It is used in conjunction with the datum peg to assist the bricklayer in gauging all further courses of brickwork when setting up the corner of a building.

Normal gauge is four courses to 300mm, i.e. each course is 75mm, which includes the brick and the joint.

Once the overall height of one course has been calculated dividers are used to mark out further courses along the gauge rod.

Pencil lines are marked across the face of the wood for each course.

Because the marks can be obliterated during use, a shallow saw cut is made along each line to give a permanent marking.

Gauge Rod