Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Unit 206 Construct cavity walling forming masonry structures

The aim of this unit is to provide the learner with the

knowledge and skills to construct walling to form masonry structures

The learner will:

3. understand how to erect cavity walling to the required specification.

The learner can:

3.4 Identify methods of cutting and preparing components

The bricklayer’s tool kit must be used with great care and properly maintained, firstly, because of the safety aspect arid secondly, because the tools can be of great expense.

When purchasing tools, consideration must be taken on how often the tools will be used.

With everyday use, the tools have to be made to be able to withstand the work.

Often this is not the case with less expensive tools.

It is a good idea to make a list of tools that will be required for the job before you start work.

Tools needed to build a cavity wall can be split into three main points

• Cutting

• Laying and Finishing.

• Checking

Bricklayers Tool Kit

To cut the bricks or blocks accurately we need a club or lump hammer and a brick bolster.

A brick hammer and a scotch hammer sometimes called a comb hammer are used to trim and shape bricks or blocks.

Additional information (See Cutting Bricks)

Scutch Hammer

Lump Hammer

Bolster Chisel

Always wear eye protection goggles when cutting bricks or blocks.

Wear Goggles

Lump Hammer

To cut the bricks or blocks accurately we need a club or lump hammer and a brick bolster.

A brick hammer and a scotch hammer sometimes called a comb hammer are used to trim and shape bricks or blocks.

Lump hammer Have different weights the popular weights are 2 lb, 2.5 lb, 3 lb, 4 lb for use with cold chisels and bolsters.

It is essential that the head is secure and checked regularly to ensure it never comes loose.

Do not hit bricks and blocks with the end of the handle nor the faced sides with the hammerhead.

Their head of hammer must not be used to hit the faces of bricks and blocks.

Clean hammers daily also check that their head has not become loose and periodic soaking in water will prevent the head from working loose.

Never hit two hammerheads together to hear the ring or feel the bounce.

Sharp pieces of metal can fly off at great speed, seriously slicing anybody in contact with them.

Scutch Hammer

A scutch hammer may have two grooved ends to receive replacement steel blades or replacement combs for trimming or cutting bricks or blocks when cut with bolster.

The square blade is used in the same way as a brick hammer.

The blades are simply knocked sideways and turned around all replaced as necessary.

A periodic soaking in water will prevent the head from working lose

Brick Hammer-Designed for cutting and setting bricks or blocks, and for chipping mortar.

The square end of the hammer is used for knocking in nails.

A periodic soaking in water will prevent the head from working lose.

Brick Hammer

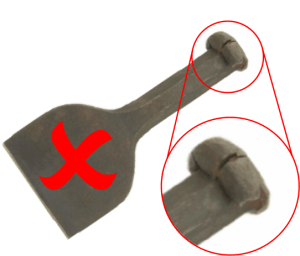

Bolster with Mushroom Head

Used for cutting bricks and concrete blocks.

Eye protection must be used at all times it is used.

The end of the handle should never be allowed to burr over after repeated hammering.

This is known as a mushroom and can splinter when being hit.

The handle end should be kept free from mushrooms by a grinding wheel which can also be used to keep the cutting edge sharp.

Bolster Chisel

Wear Goggles

Protective Footwear

Hand Protection

Protective Footwear

High Visibility

In addition to gloves and safety footwear, it is necessary to wear goggles when cutting bricks and blocks because of the risk of splinters flying from the cutting process.

Observers should be protected against this hazard.

Although there is some impact noise hammer to chisel and chisel to brick it is not usually necessary to wear ear defenders.

Additional information on Mandatory Signs go to (Mandatory Signs)

To build any wall we need a trowel to lay the bricks or blocks, and for the face brickwork, a pointing trowel and a jointer to provide a finish to the joints.

Brick Trowel

These come in various shapes and sizes ranging between ten and fourteen inches.

One side of the trowel has a more rounded edge, this being for rough cutting, however, this use is not advised for the beginner.

The measurements are the actual blade size, the width of trowel also varies and beginners will find a narrower trowel easier to use.

The rounded side on the trowel makes it suitable for both left and right-handed operators.

When the trowel is not in use for a period of time, clean it off-dry and apply a light coat of oil to avoid rusting.

A smaller version of the brick trowel but with both edges being straight, these are used for certain types of pointing or to add a finish to the brickwork and should be maintained as the brick trowel.

Pointing Trowel

Pointing Hawk

A small hawk is used when pointing a lot and makes it easier to hold the mortar.

Used for putting a finish to the joints in brickwork.

A half-round joint is also known as a bucket handle finish.

Two types are shown, these can now be bought from shops but an old pail or bucket handle can be bent to a suitable shape.

Jointing Tools

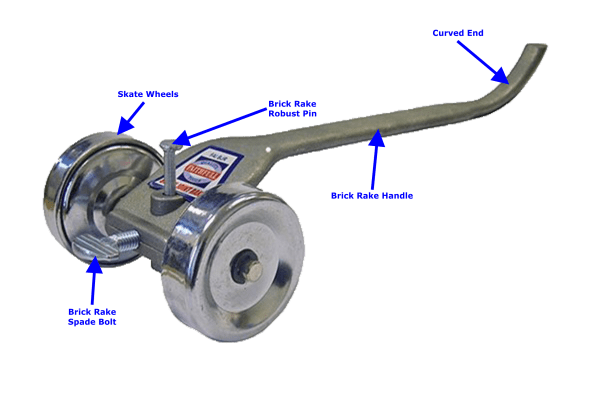

Brick Chariot

The Brick Chariot or Brick Joint Raker are used to removing mortar from between brickwork (Bed Joints and Perps) recess pointing

Adjustable Brick rake pin removes the mortar from the face of the wall to the required depth normally 5 mm or more, then finished off jointing with the curved end of the handle.

Jointing is a process which is ongoing as a wall is being built, on the other hand, pointing is a process where you remove existing mortar bed joint and perps to a depth of approximately 10mm and apply new mortar.

Brick Chariot Skate Wheels

The skate wheels are hard wearing wheels that move along the bricks as the robust pin rakes out mortar.

Brick rake spade bolt

The spade bolt is twisted to secure the robust pin in place.

Brick Chariot Robust Pin

The robust pin can be moved up and down by twisting the spade bolt to release the pin and then tightening it back up to secure the pin.

The flat end of the robust pin sticks out into the mortar and the sharp point sticks up out the top of the brick chariot.

Brick Chariot handle

The aluminium handle is gripped in the operator’s hand and runs parallel to the mortar.

Curved End

This type of design with a curved end allows the brick rake to double up as a ‘brick joint trowel’ which you run along freshly laid mortar before it sets to neaten up the joint.

Components of a Brick Chariot

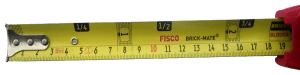

Tape Measure

A Tape Measure is needed to set out and check dimensions and cutting components.

Tape measures come in different sizes and different materials they also can have a combination of metric and imperial measurements or just metric.

The blade lock is useful for repetitive measuring and also enables easier reading when measuring in restricted or confined spaces where the blade may be locked in the measuring position but read away from the work.

A spring return refers to an automatic spring return mechanism when the blade is rewound.

Tapes without automatic return are sometimes described as ‘pull-push’.

Spring return tapes should not be allowed to fly back uncontrolled from the extended position to prevent hook/blade damage.

Components of a Tape Measure

Brick Tape Measure

Brick Tape Measure gives you the measurement of bricks and block lengths and course height

Brick Tape Measure Blade

Closed Steel Tape Measure

When setting out and checking dimensions from Working Drawings only use steel tape measures as they do not stretch like fibreglass tape measures.

Open Steel Tape Measure

Closed Case Fibre Tape Measure

With fibreglass tape measures can be washed with soap and water

With steel takes you must wipe clean and make sure the blade is dried before allowing it to go back into its case otherwise the steel tape will rust

Open Reel Fiberglass Tape Measure

Spirit Level

This will be the most expensive part of the tool kit.

It is used to check the brickwork as it is laid to check that the bricks are level (horizontal) and plumb (vertical).

These also come in various sizes.

The typical sizes for everyday work are 900 or 1200 millimetres long.

They are available in wood or metal, the metal ones are easier to keep clean as they are easy to wash to remove mortar.

Similar to the Spirit Level above, it has two bubbles, (one for levelling, the other for plumbing) but is smaller.

It is very handy for decorative panels and soldier brick courses

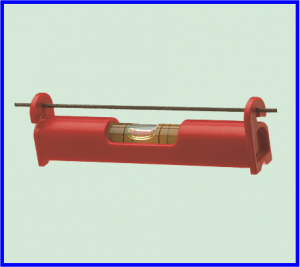

Line Level

The line-level is a single vial in a metal case with a hook on each end for hanging on a cord.

It is used to check whether two points are level, such as two points on a floor or in an elevation.

It must be used with a tightly stretched cord.

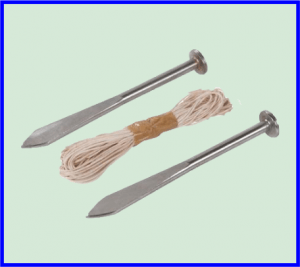

Line and Pins

These are used as a wall is being built up to provide a guide for the bricks between the pins.

The pins are tapered at the ends to allow them to be inserted into mortar joints.

It is important that the line is kept free of knots and clean of mortar.

The line is also used without the pins using

corner blocks.

Additional information can be found online level (Line Pins and Corner Blocks)

Corner Blocks and Line