Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Employers have duties concerning the provision and use of Personal Protective Equipment (P.P.E.) at work.

PPE is equipment that will protect the user against health or safety risks at work.

It can include items such as safety helmets, gloves, eye protection, high-visibility clothing, safety footwear and safety harnesses.

It also includes respiratory protective equipment (RPE).

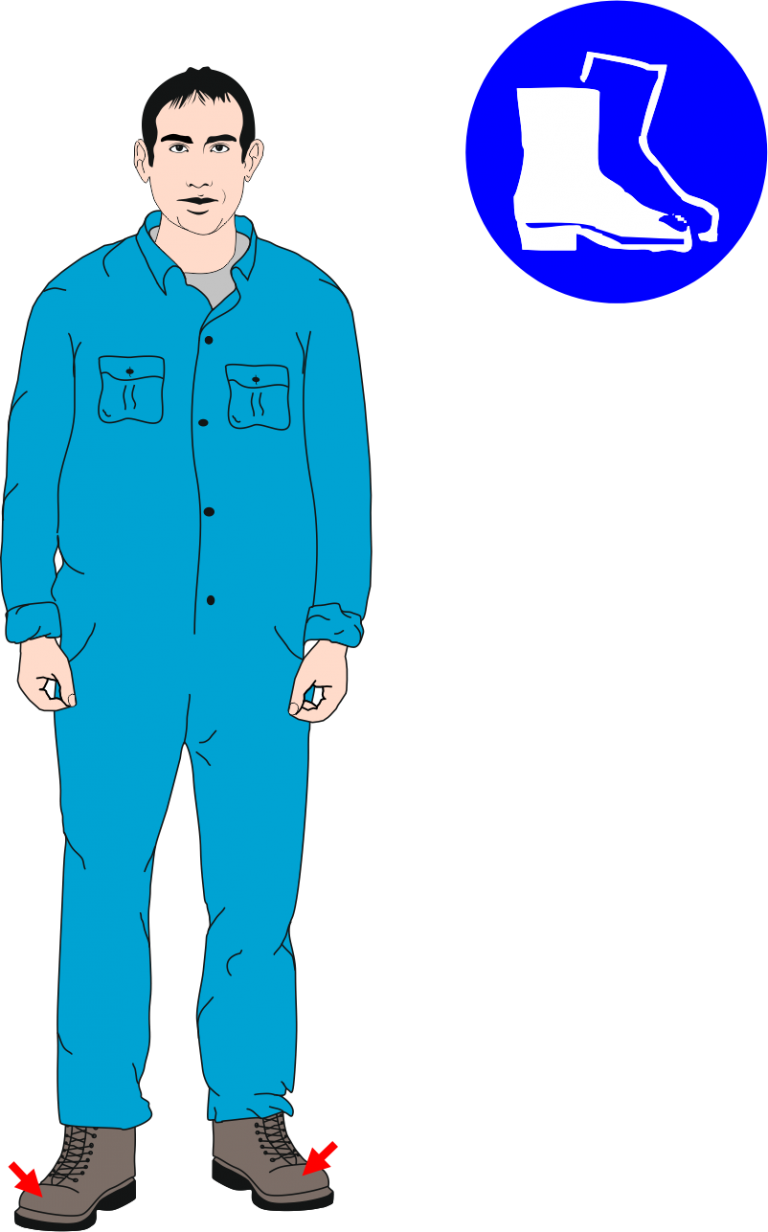

Wear Safety Boots

Purpose

Wet, hot and cold conditions, electrostatic build-up, slipping, cuts and punctures, falling objects, heavy loads, metal and chemical splash, vehicles

Options

Safety boots and shoes with protective toecaps and penetration-resistant, mid-sole wellington boots and specific footwear, eg foundry boots and chainsaw boots

Note

Footwear can have a variety of sole patterns and materials to help prevent slips in different conditions, including oil – or chemical-resistant soles.

It can also be anti-static, electrically conductive or thermally insulating.

Appropriate footwear should be selected for the risks identified

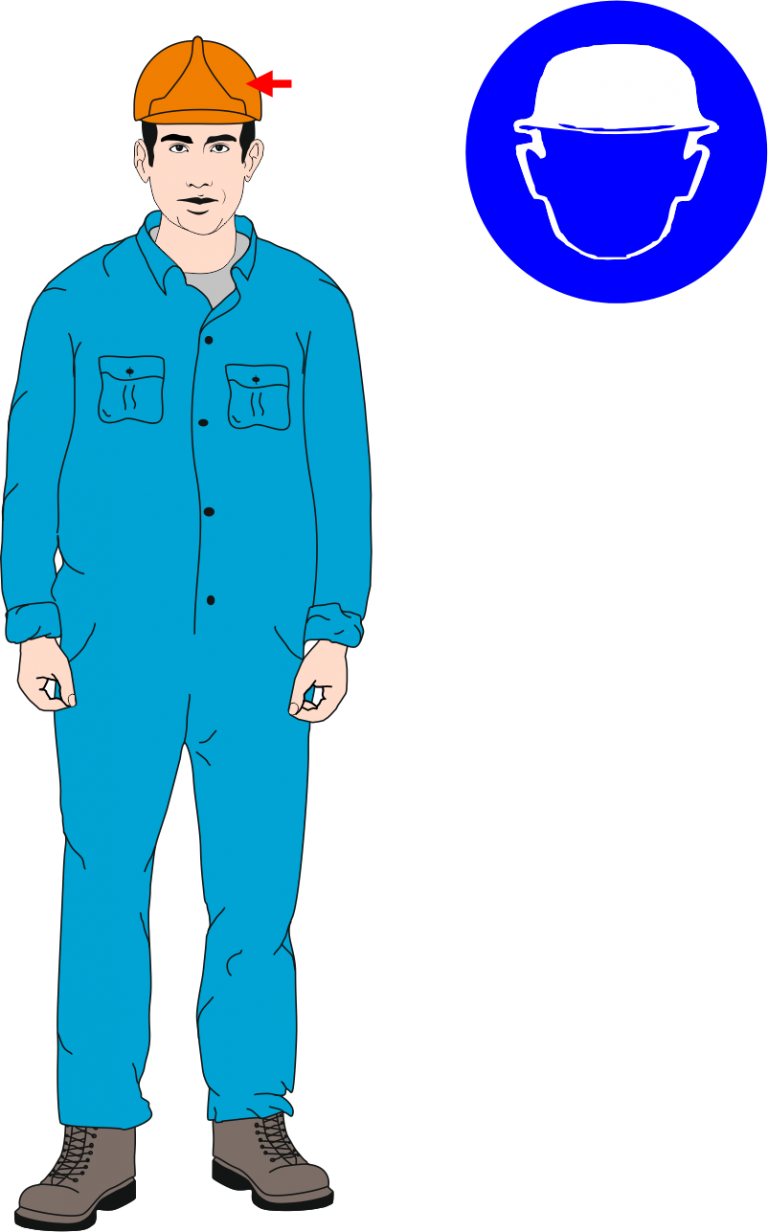

Purpose

Impact from falling or flying objects, risk of head bumping, hair getting tangled in machinery, chemical drips or splash, climate or temperature

Options

Industrial safety helmets, bump caps, hairnets and firefighters’ helmets

Note

Some safety helmets incorporate or can be fitted with specially-designed eye or hearing protection.

Don’t forget neck protection, eg scarves for use during welding.

Replace head protection if it is damaged

Wear Safety Helmet

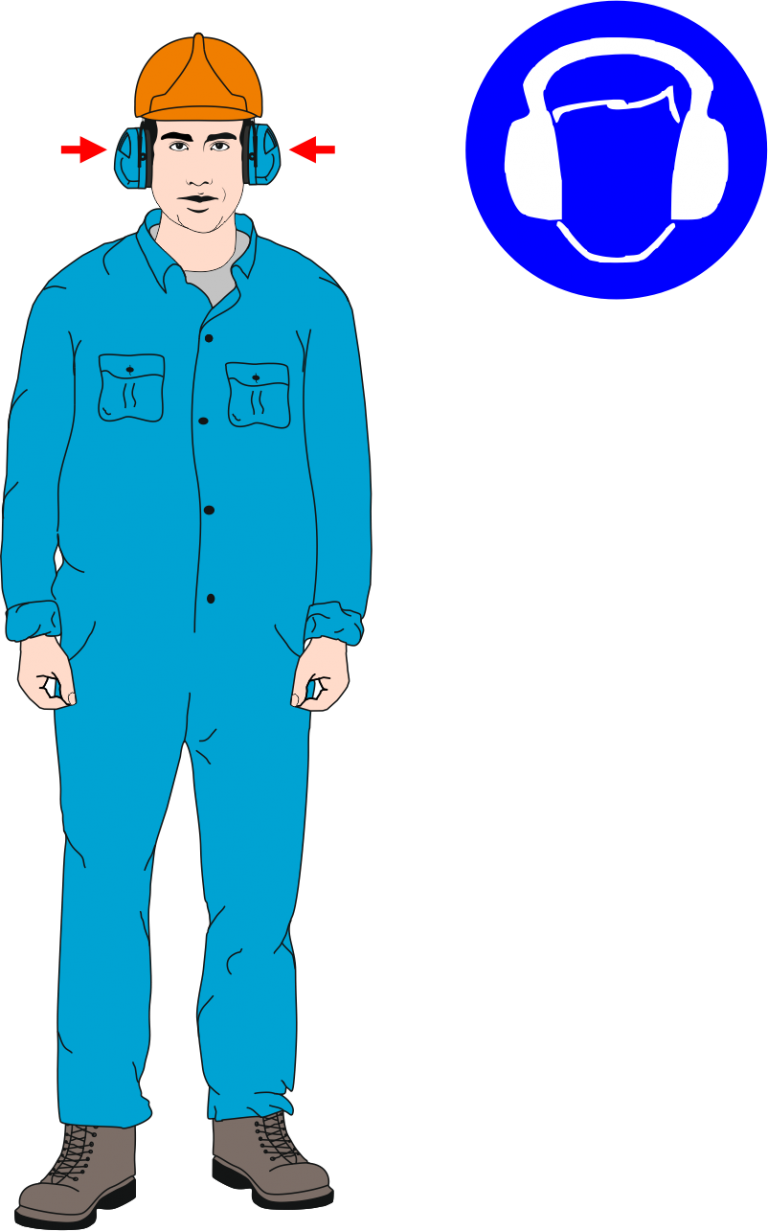

Wear Ear Defend

Purpose

Noise – a combination of sound level and duration of exposure, very high-level sounds are a hazard even with short duration

Options

Earplugs, earmuffs, semi-insert/canal caps

Note

Provide the right hearing protectors for the type of work, and make sure workers know how to fit them

Choose protectors that reduce noise to an acceptable level, while allowing for safety and communication

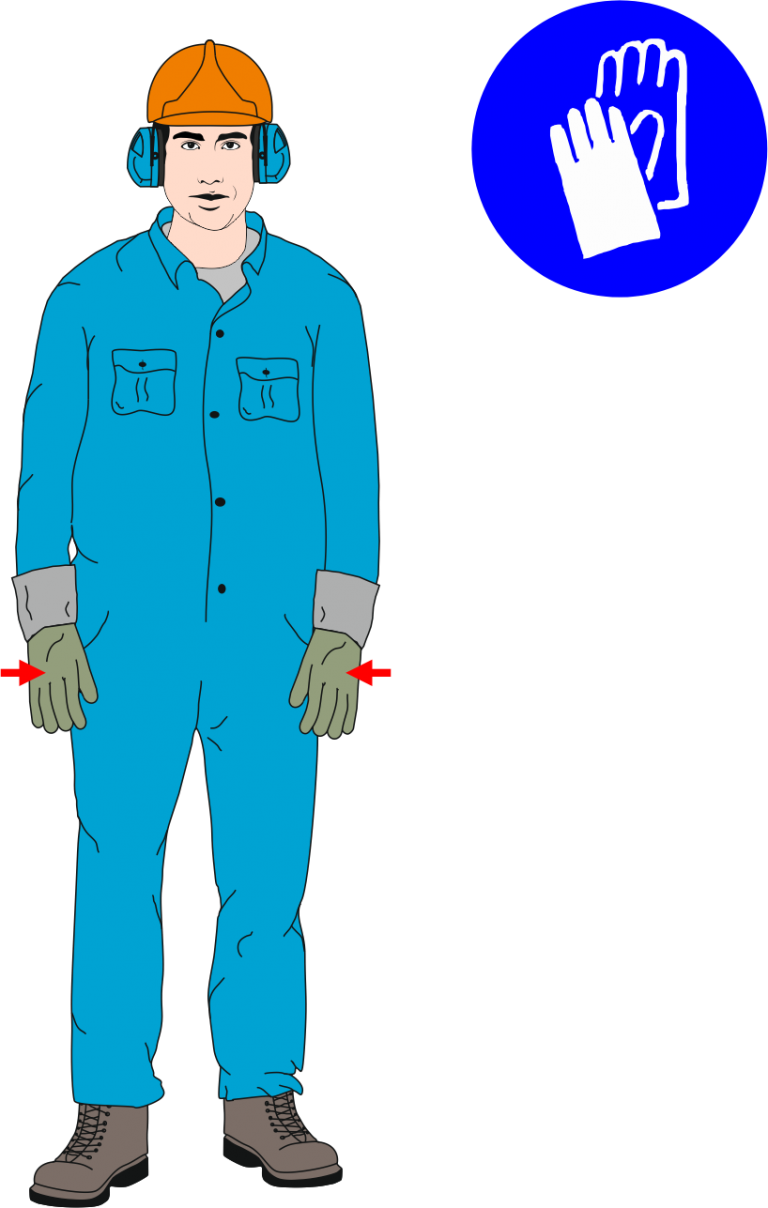

Purpose

Abrasion, temperature extremes, cuts and punctures, impact, chemicals, electric shock, radiation, vibration, biological agents and prolonged immersion in water

Options

Gloves, gloves with a cuff, gauntlets and sleeving that covers part or all of the arm

Note

Avoid gloves when operating machines such as bench drills where the gloves might get caught

Some materials are quickly penetrated by chemicals – take care in selection, see HSE’s skin at work website

Barrier creams are unreliable and are no substitute for proper PPE.

Wearing gloves for long periods can make the skin hot and sweaty, leading to skin problems.

Using separate cotton inner gloves can help prevent this

Wear Safety Gloves

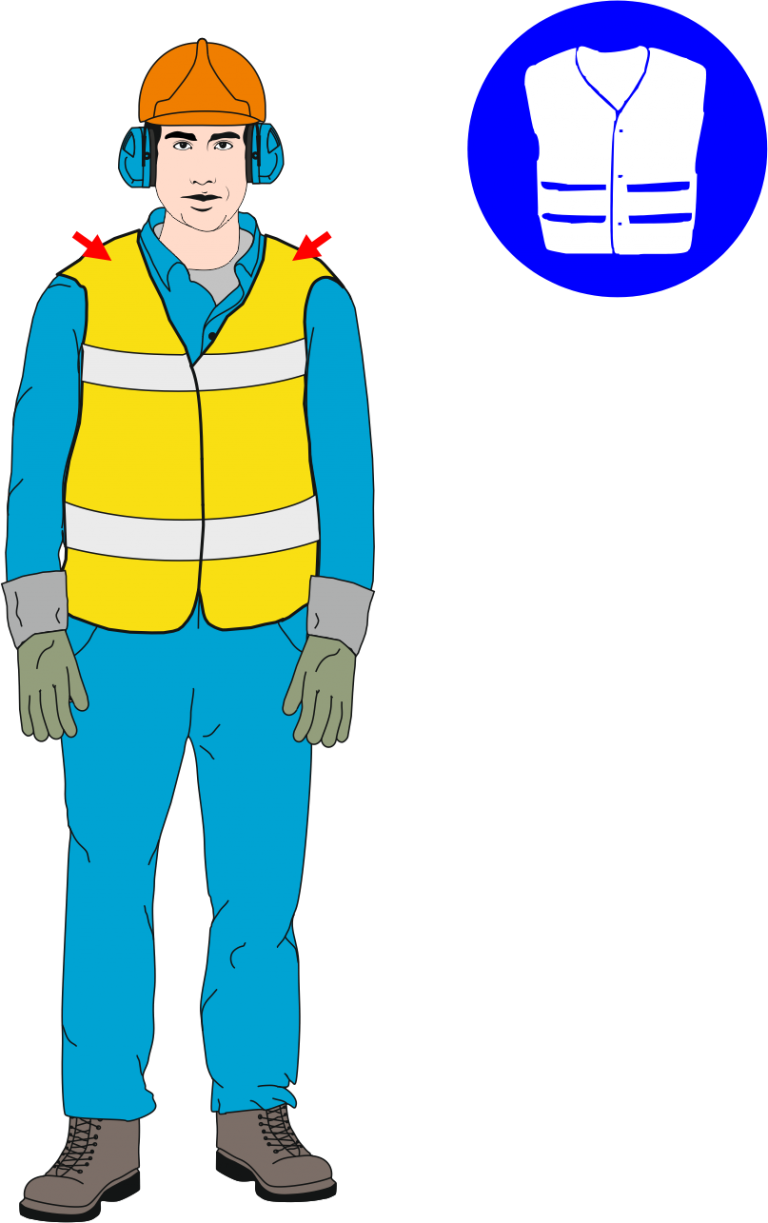

Wear (Hi-Viz) Jacket

Purpose

Temperature extremes, adverse weather, chemical or metal splash, spray from pressure leaks or spray guns, impact or penetration, contaminated dust, excessive wear or entanglement of own clothing.

Options

Conventional or disposable overalls, boiler suits, specialist protective clothing, eg chain-mail aprons, high-visibility clothing.

Note

The choice of materials includes flame-retardant, anti-static, chain mail, chemically impermeable, and high-visibility. Don’t forget other protection, like safety harnesses or life jackets.

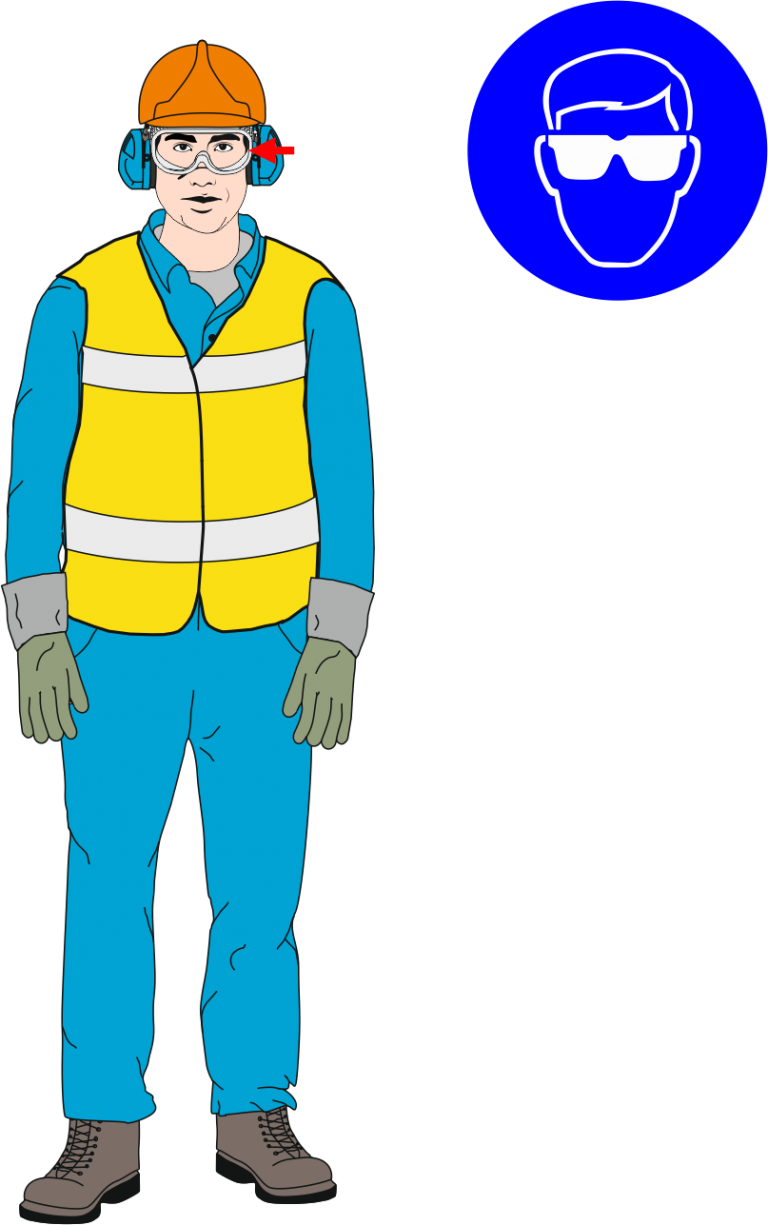

Purpose

Chemical or metal splash, dust, projectiles, gas and vapour, radiation

Options

Safety spectacles, goggles, face screens, faceshields, visors

Note

Make sure the eye protection chosen has the right combination of impact/dust/splash/molten metal eye protection for the task and fits the user properly

Wear Goggles

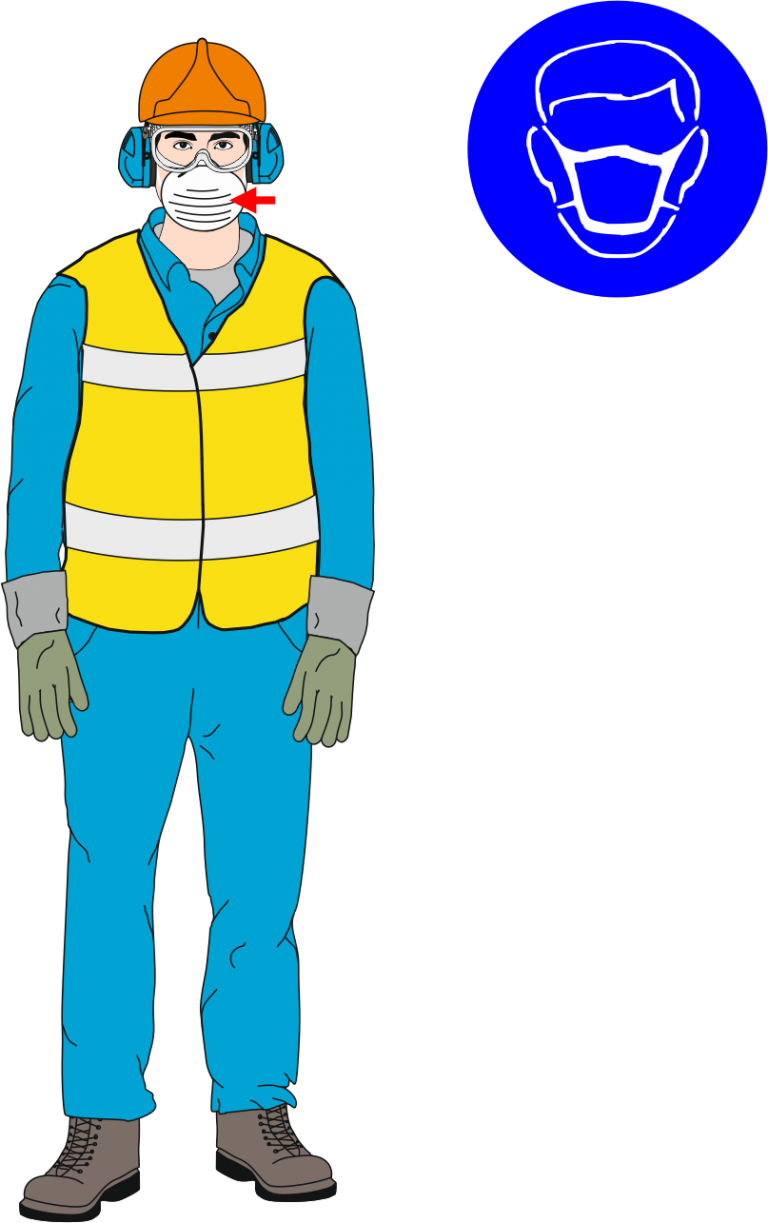

Wear Dust Masks

Purpose

Dust, vapour, gas, oxygen-deficient atmospheres.

Options

Disposable filtering face-piece or respirator, half- or full-face respirators, airfed helmets, breathing apparatus.

Note

The right type of respirator filter must be used as each is effective for only a limited range of substances.

Where there is a shortage of oxygen or any danger of losing consciousness due to exposure to high levels of harmful fumes, only use breathing apparatus – never use a filtering cartridge.

Filters only have a limited life; when replacing them or any other part, check with the manufacturer’s guidance and ensure the correct replacement part is used.

Equipment is kept clean and in good repair – follow the manufacturer’s maintenance schedule (including recommended replacement periods and shelf Lives)

Do not use PPE if it is damaged and in need of repair.

It is the responsibility of the employee to make their supervisor aware as soon as PPE becomes damaged so that new PPE can be obtained.

Do not attempt to repair PPE.

Identify who is responsible for maintenance and how to do it;

Simple maintenance can be carried out by the trained wearer, but more intricate repairs should only be done by specialists;

Replacement parts match the original, eg respirator filters;

Additional learning resources for this unit can be found on the following links