Teaching and learning resources for the construction industry with NVQ and Diploma Assessment Criteria

Detached House

Older traditional houses in 1900-1930 were built with a solid external wall either out of stone or brick manufactured locally.

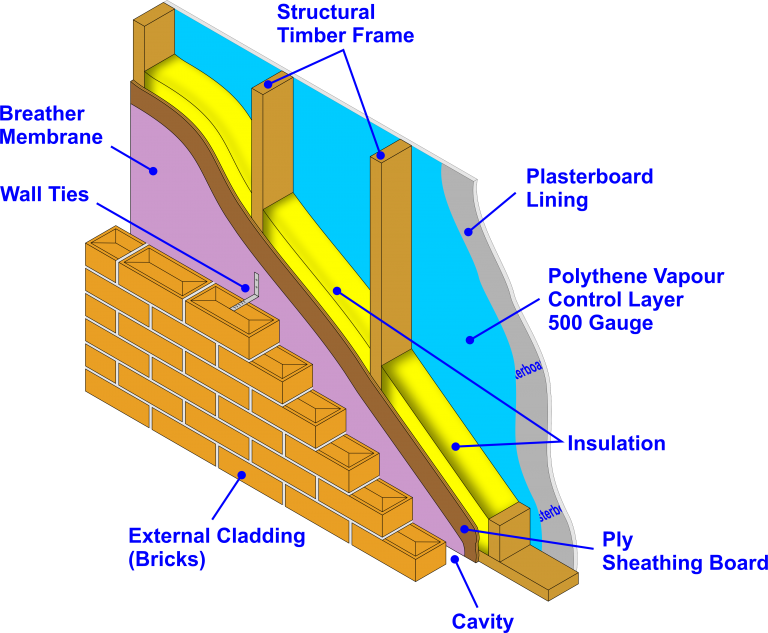

Traditional masonry houses have an internal and external wall forming a cavity which are normally referred to as leaves which prevents rainwater from penetrating through from the outer leaf to the inner leaf causing damp patches.

Early cavity walls had a 50mm cavity with metal wall ties, which has been replaced with mild steel coated with zinc to inhibit rust corrosion.

Cavities which have no insulation lose about third of their heat through the leaves of the wall, due to the increase in fuel prices and concern about the environment cavity walls have been increased from 50 mm 200 mm accommodating increased thickness of insulation and still maintain a cavities against rain penetration.

Detached Bungalow

Detached House

Homes come in various shapes and sizes can come in single units or several units grouped together, various terms are used in the way homes are constructed here are just a few

A detached house sits on its own ground with no other houses attach to its structure also can be a Detached Bungalow.

Semi-Detached House

Semi-Detached House

Semi-Detached Bungalows

Semi-detached house share at least one party wall in the construction which separates the two units.

Party walls is inherently thick and usually ranges from 250 to 300mm, half the thickness of the party wall will sit on the adjoining plots of land.

Just like detached houses, bungalows can be semi-detached as well.

Terrace housings are three or more units connected together separated by a party wall each side of the property.

The main advantage here is that this type of construction saves a great deal of space.

The end terraced house only has one party wall, you also can have a row of terraced bungalows.

Modern Terrace House

Traditional Terrace Houses

Modern Terrace Bungalow

The earliest form of steel frame building started around 1850s using of cold-formed steel members for construction of buildings.

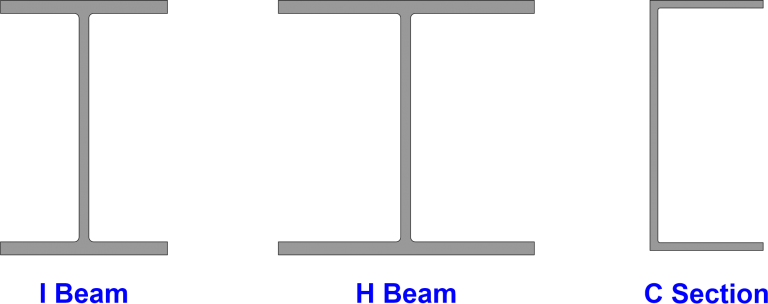

Steel frame are manufactured by passing a heated steel which softens the steel before going between two large rollers which form several shapes, some steel beams are named because of the shape of their profile for example.

Steel Frame

Universal Beam (UB) is often referred to as an I beam

Universal Column (UC) an H beam

Parallel Flanged Channel (PFC) also called PFC or C-section

Shapes of Steel

Additional information on steel beams can be found at this location

https://road-to-learning.com/2021/06/02/types-of-steel-beams/

Steel frames are manufactured off-site which is tailored into different shapes and sizes, and deliver to site then assembled by Steel Fixers with the aid of a crane .

Corrosion is a major factor when using steel frame construction, operatives must follow the architects instructions to eliminate this issue.

Insulation is poor in steel houses steel conducts heat 300 to 400 times faster than wood and reduces the insulating properties of wall insulation by 60% because of thermal bridging.

The steel frame are self-supporting which is in-fill with concrete blocks or other materials which is then covered with various types of cladding materials such as,

Natural Stone Panels

Masonry Units (Bricks/Blocks or Prefabricated Masonry Units)

Profiled Metal Cladding

Pre-Cast Concrete Cladding Panel

Rain-Screen Cladding

Curtain Wall

Spider Glazing

One of the biggest challenges with a completed Steel framed property is that retrospectively it can often be very difficult to identify that it is actually a Steel framed structure

High-Rise Housing

Low-Rise Housing

Why build a High-Rise Building these types of buildings take up less ground to build on (Building Footprint), this means it has a small roof area with very tall frontages (Elevations)

Modern construction methods and materials greater heights can be achieved using a smaller building footprints which is to perimeter of the building on the outside edge of the walls of the building.

Conventionally in construction the building footprint is the area of a building measured from the outer surface of the exterior of the building multiplied by the depth measured in the same manner to give a square area.

The main reasons for building high-rise buildings is to solve the problem of less available building land for development also helps to solve a high density population.

The Burj Khalifa remains the World’s Tallest Building in 2020 it stands at 828 meters.

What’s inside the Burj Khalifa

900 Residences Apartments

Corporate Suites

Armani Hotel Dubai

Highest Restaurant

Leisure and Retail

The Offices

The Club

Parking for 3,000.

Water Features

Tallest Building the Burj Khalifa

Traditional Timber Framed

Timber frame houses have been around for many hundreds of years, for example, timber frame Tudor houses are very easily recognised with their black timber frames with white infill panels.

Oak timber frames were used and wooden pegs to secure the joints.

When the frame was completed the area’s between the timbers would have been infilled with a technique known as ‘wattle and daub’.

Wattle and daub is a method of weaving small branches between parts of the timber frame and then ‘plastering’ onto the weaved branches a mixture of clay, horsehair and sometimes horse dung! With water.

This could be smoothed before drying, then painted with limewash given that white colour finish.

The wattle and daub began to disappear as infill when locally made bricks became more affordable.

Modern timber frames are fabricated off-site into prefabricated units like walls, floors and roofs.

Compartment units are prefabricated individual rooms or sections of the building, for example kitchens and bathrooms can be supplied as finish compartment units.

Construction time is much shorter for timber frame houses, a typical semidetached unit after the concrete slab has been laid, is 4 to 5 days to a higher standard of workmanship.

Modern Timber Framed House

Render Not on Self-Supporting Blockwork

Tile or Slate Cladding

Metal Sheet Cladding

Brick Slips

Timber Cladding

Shingles

One of the biggest challenges Just like steel frame After timber frame has been completed it is difficult to identify it is actually a timber frame construction.

Prefabrication Unit

Three main steps 1.

1. Manufacturing components off-site (Factories or Workshops)

2. Transport components to site

3. Assembly at needed positions

Prefabrication Unit

Prefabrication Unit

Prefabricated modular buildings have several applications for example residential use, offices, Canteens, Classrooms, and even Temporary Construction Sites welfare Facilities.

Can be delivered as a complete unit and have modular units up and running within a day, easy to remove for relocation.

Additional learning resources for this unit can be found on the following links